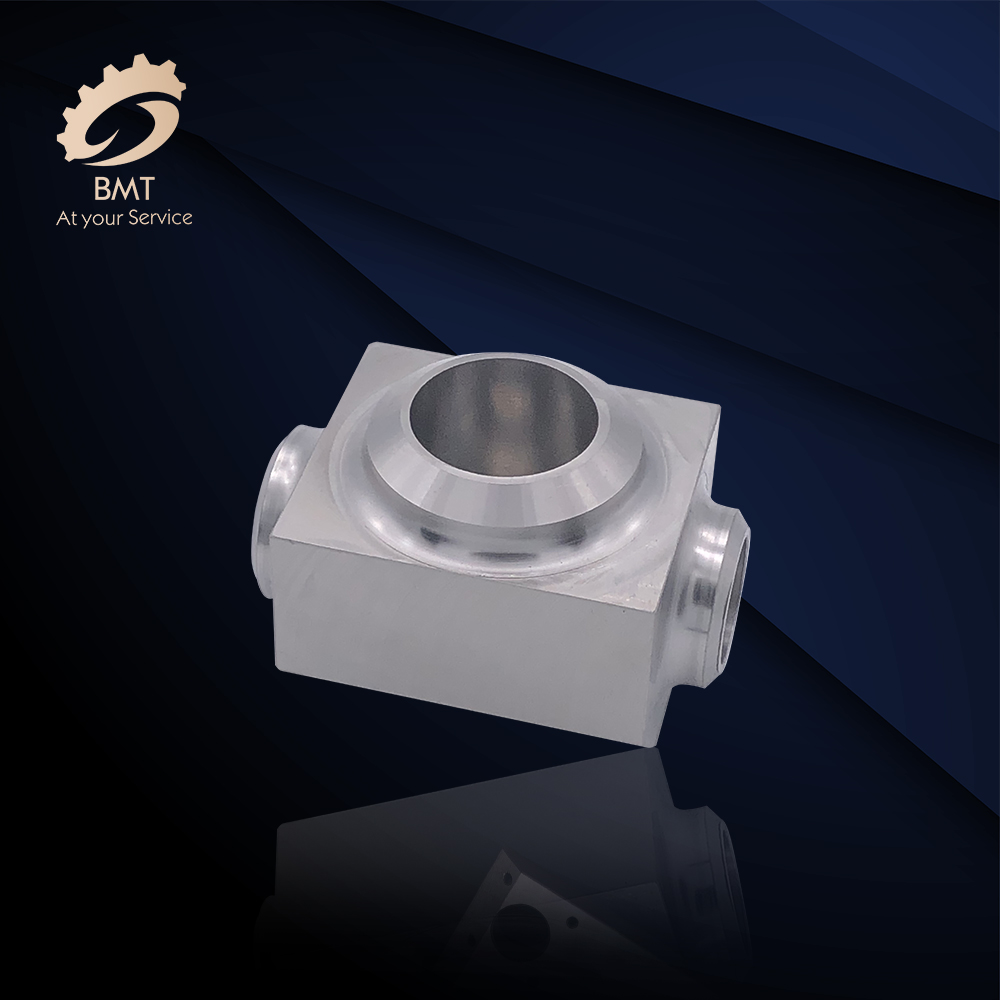

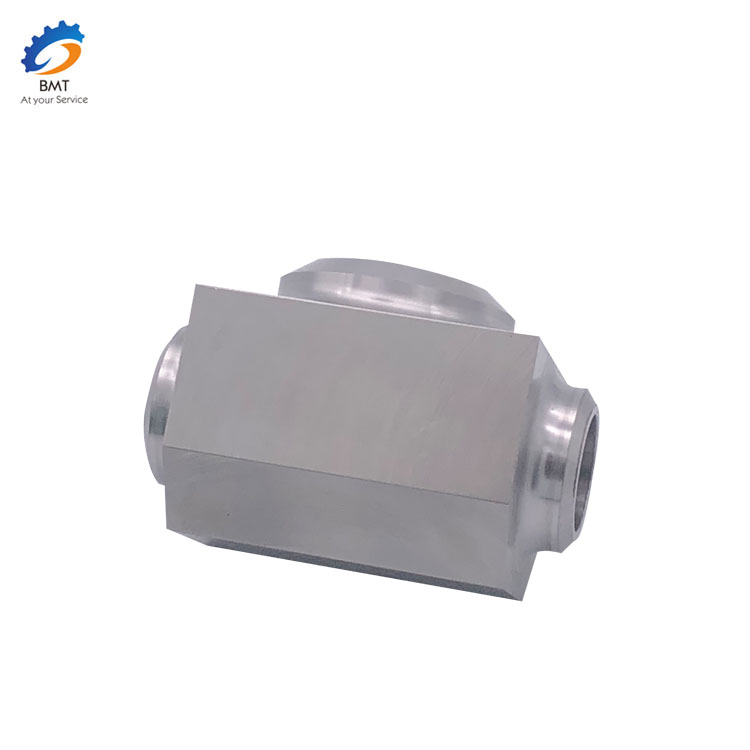

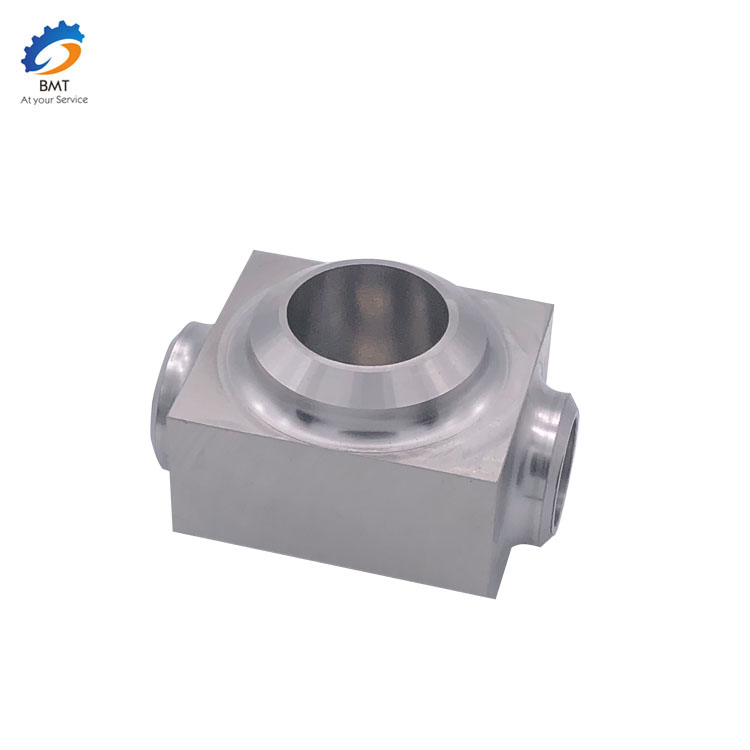

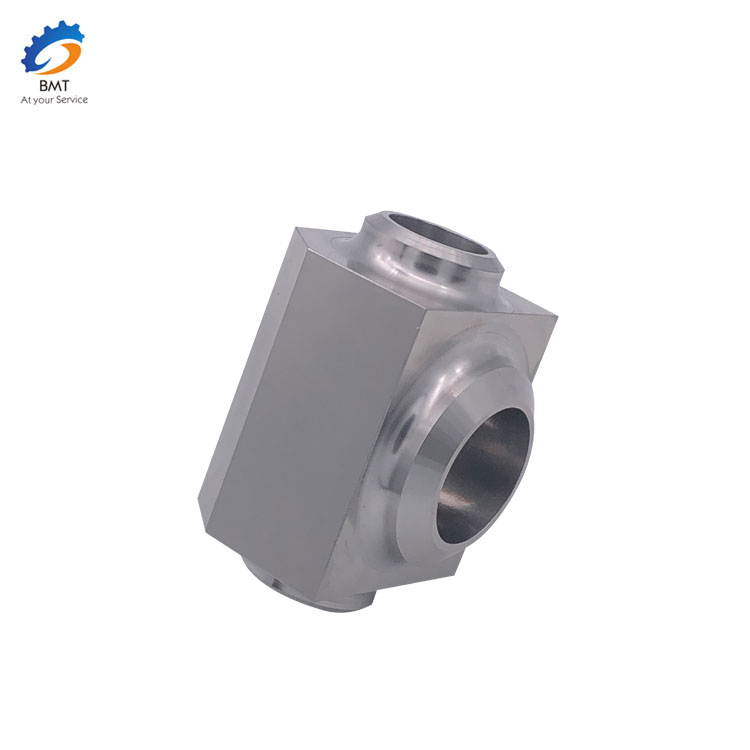

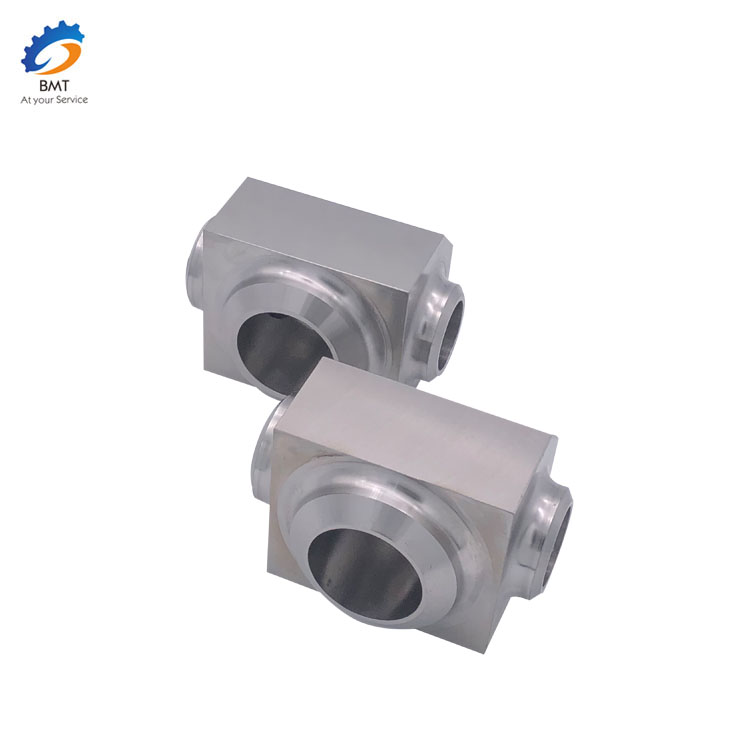

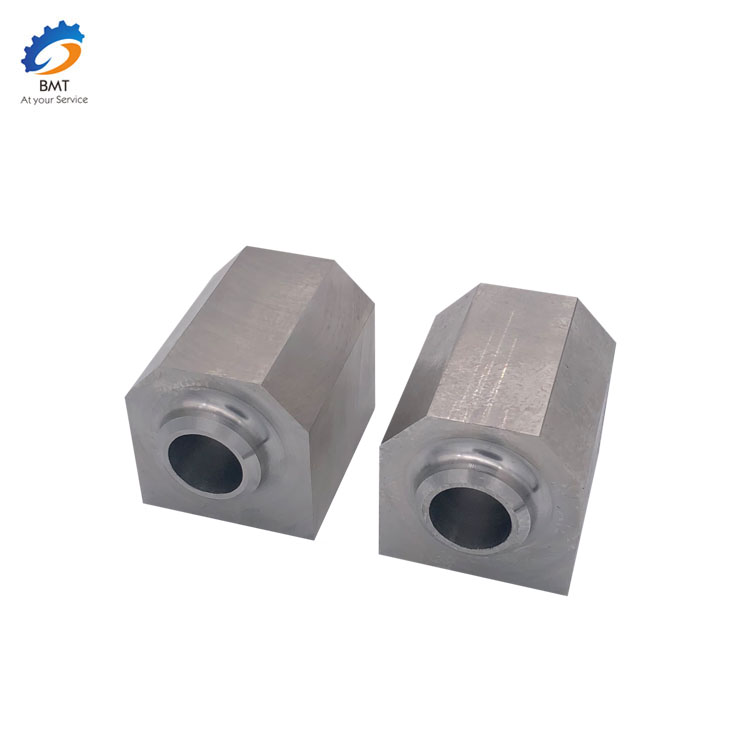

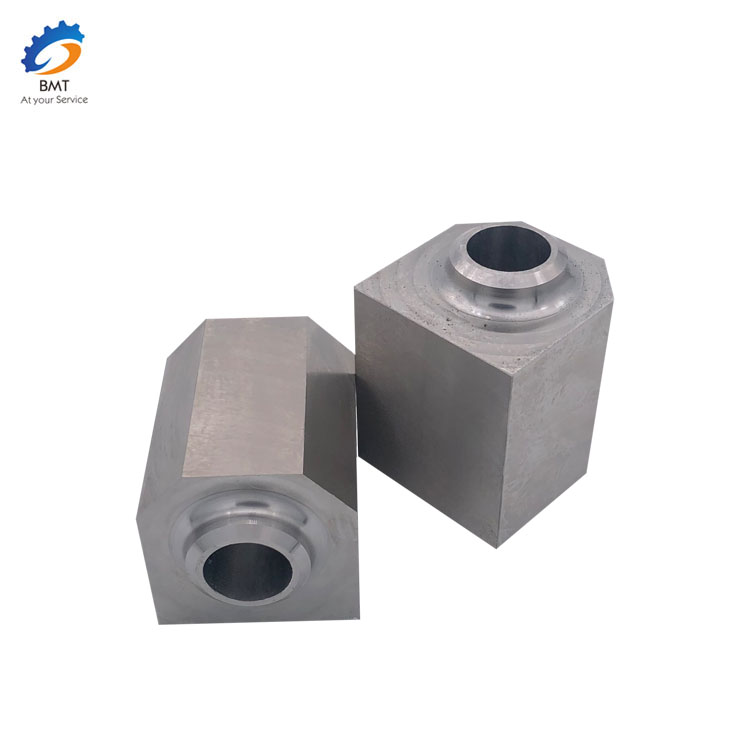

CNC Auto Parts Professional Chaw tsim tshuaj paus

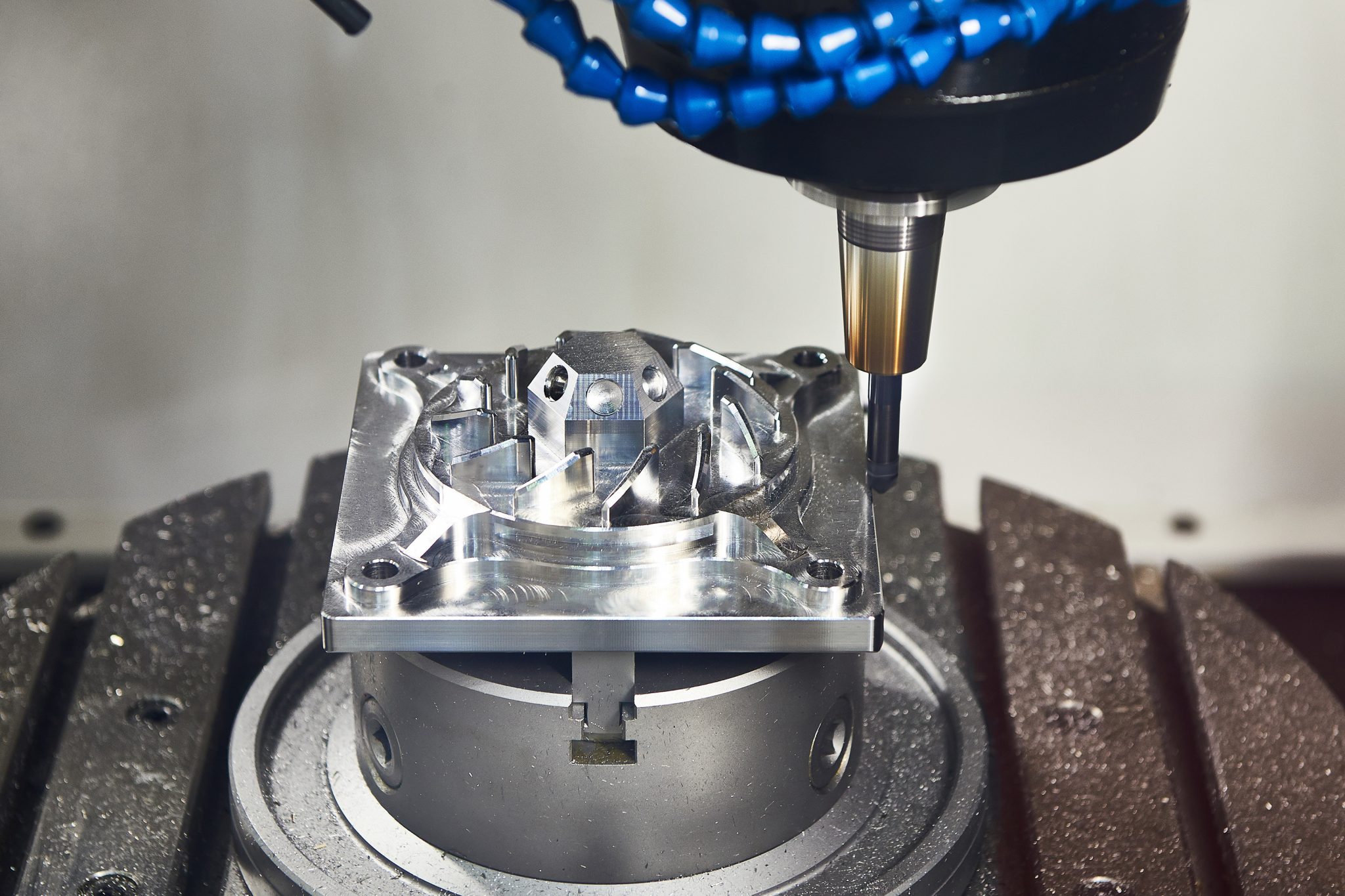

BMT yog tshwj xeeb hauv precision machining, uas tsis yog-tus qauv kev ua, CNC tej qhov chaw ua, cov lej tswj tsheb qhov chaw ua, batch titanium alloy nyob rau hauv high precision qhov chaw ua, ncej qhov chaw ua, semiconductor khoom qhov chaw ua, thiab lwm yam, muaj kev nplua nuj, nruab. nrog CNC machining chaw, CNC lathes, hlau txiav, milling tshuab, sib tsoo tshuab, carved, peb coordinates ntsuas ntsuas, qhov siab ntsuas ntsuas thiab lwm yam high precision ntau lawm thiab nrhiav kom tau cov khoom.

1. Txheeb xyuas cov duab kos duab thiab txiav txim siab cov txheej txheem ua haujlwm

Raws li cov txheej txheem kev kos duab muab los ntawm tus neeg siv khoom, cov txheej txheem cov neeg ua haujlwm tuaj yeem txheeb xyuas cov duab, qhov tseeb qhov tseeb, qhov roughness ntawm qhov chaw, cov khoom siv ua haujlwm, yam tsis muaj thiab kho cua sov ntawm qhov chaw, thiab tom qab ntawd xaiv lub tshuab cuab yeej, cuab yeej, txiav txim siab qhov chaw clamping. ntaus ntawv, txheej txheem txheej txheem, ua ntu zus thiab qhov loj ntawm qhov txiav ntau npaum li cas.Nyob rau hauv tus txheej txheem ntawm kev txiav txim siab cov txheej txheem machining, cov lus txib ua haujlwm ntawm CNC tshuab cuab yeej yuav tsum tau txiav txim siab tag nrho, muab kev ua si tag nrho rau kev ua haujlwm ntawm lub tshuab cuab yeej, kom txoj kev ua haujlwm yog qhov tsim nyog, tsawg dua riam lub sijhawm thiab lub sijhawm ua haujlwm luv.

2. Xam cov nqi sib koom tes ntawm cov cuab yeej txoj hauv kev tsim nyog

Raws li lub geometric loj ntawm lub machining ib feem thiab lub teeb programming kev tswj qhov system, txoj kev txav ntawm qhov chaw ntawm txoj kev cutter yog xam, thiab tag nrho cov ntaub ntawv ntawm txoj hauj lwm cutter tau txais.General CNC system muaj kev ua haujlwm ntawm linear interpolation thiab ncig interpolation, rau qhov yooj yim cov qauv qauv, xws li cov kab thiab arc contour machining, tsuas yog yuav tsum xam cov ntsiab lus geometric ntawm qhov pib thiab qhov kawg taw tes, lub voj voog ntawm lub voj voog ( los yog lub vojvoog arc), ob lub ntsiab lus geometrical kev sib tshuam taw tes lossis tangent point kev tswj hwm qhov tseem ceeb.Yog hais tias lub nc system tsis muaj cov cuab yeej them nyiaj ua haujlwm, cov cuab yeej nruab nrab trajectory coordinate tus nqi yuav tsum raug xam.Rau cov khoom uas muaj cov duab nyuaj (xws li cov khoom uas tsis yog lub voj voog thiab qhov chaw), nws yuav tsum tau siv cov kab ncaj nraim (los yog ntu arc) kom kwv yees qhov tseeb nkhaus lossis nto, thiab suav cov nqi sib koom tes ntawm nws. nodes raws li qhov yuav tsum tau machining raug.

3. Sau CNC machining program rau qhov chaw

Raws li qhov chaw ntawm riam txoj kev los xam cov cuab yeej txoj kev cov ntaub ntawv thiab cov txheej txheem tsis tau txiav txim siab thiab pab txiav txim, programming neeg ua hauj lwm yuav ua tau raws li kev siv NUMERICAL tswj system teev nyob rau hauv cov lus qhia ua hauj lwm thiab cov kev pab cuam hom, seem los ntawm ntu sau cov ntu ntawm cov txheej txheem ua haujlwm.Kev saib xyuas yuav tsum tau them rau: ua ntej, kev tsim qauv ntawm kev sau ntawv yuav tsum yooj yim rau kev nthuav qhia thiab sib txuas lus;Thib ob, hauv kev siv CNC tshuab cuab yeej kev ua tau zoo thiab cov lus qhia nyob rau hauv lub hauv paus ntawm kev paub tag nrho, kev qhia txog kev siv cov txuj ci, kev txawj ua haujlwm.