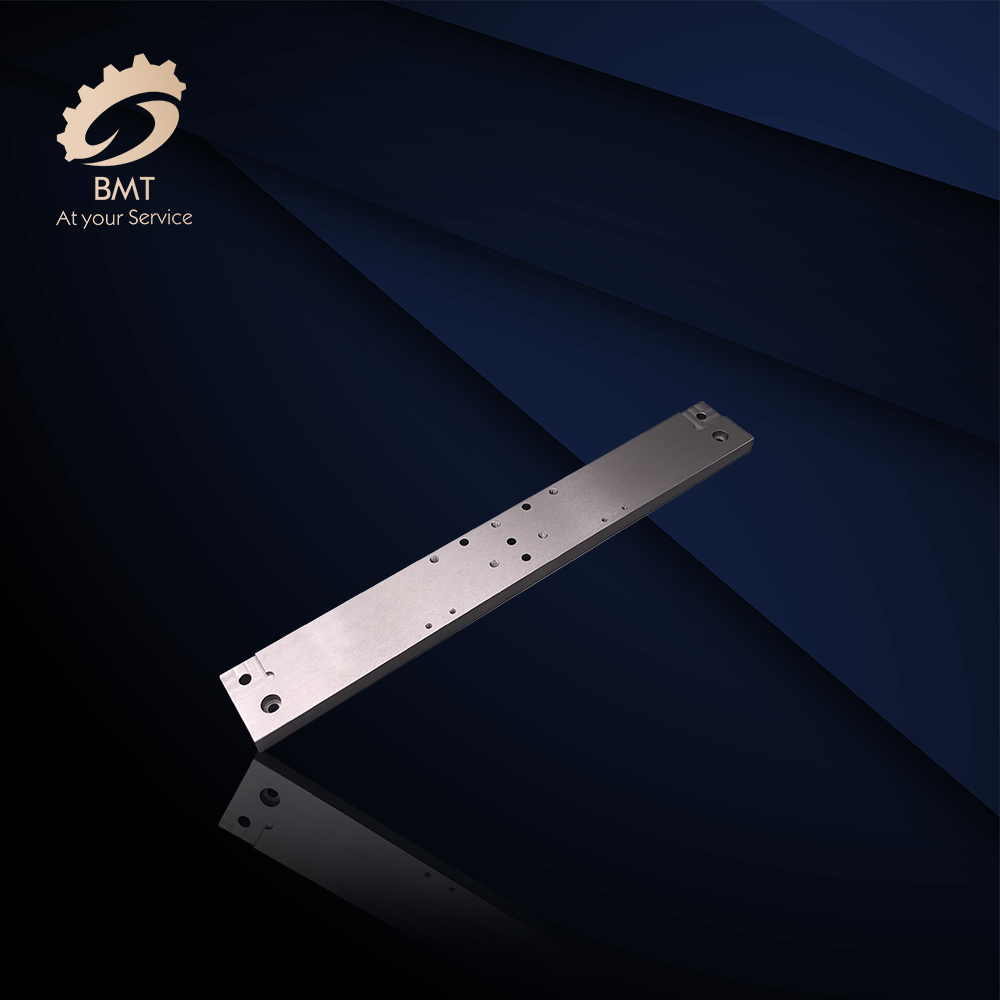

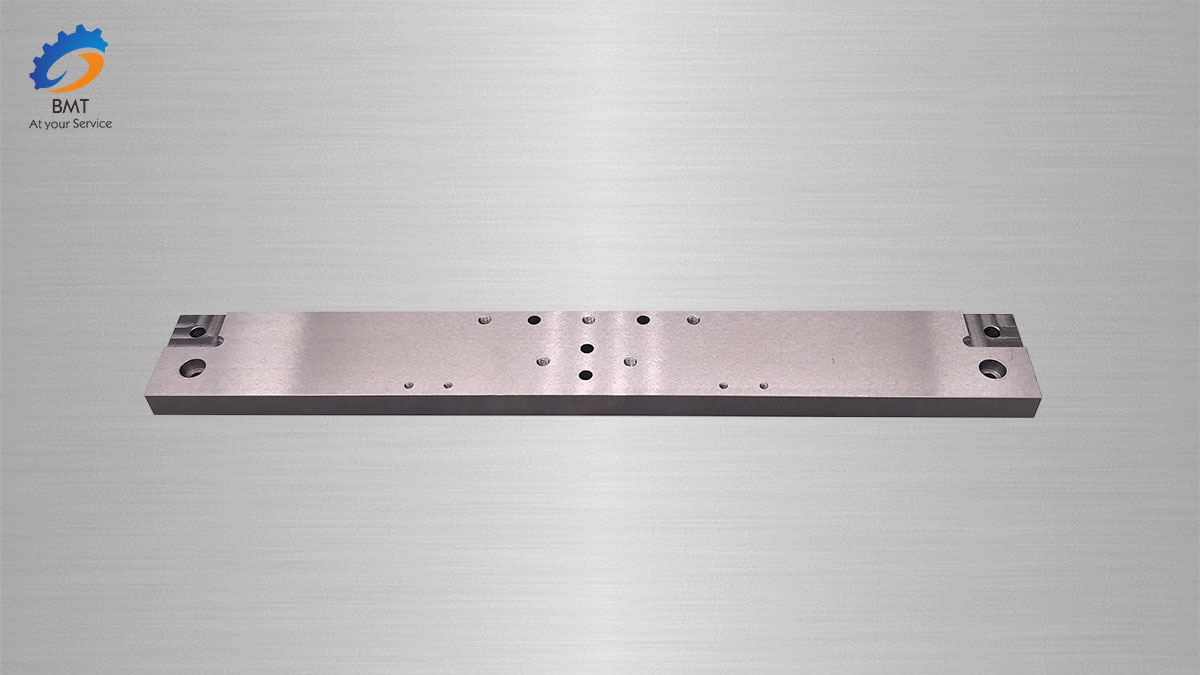

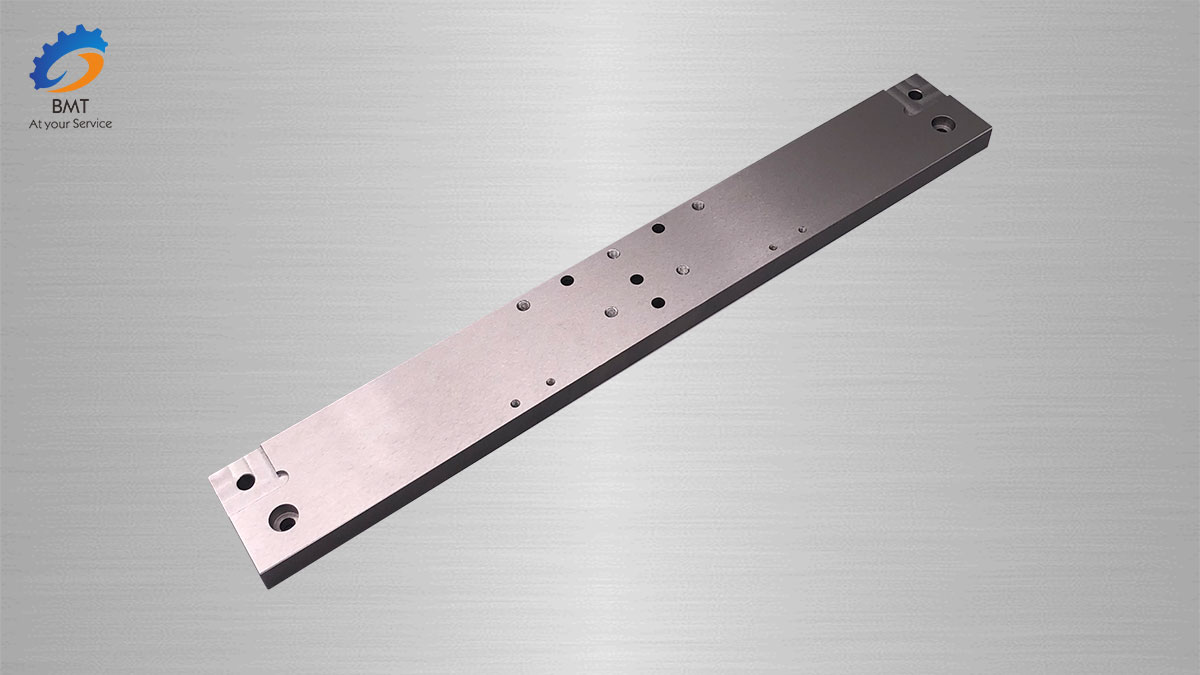

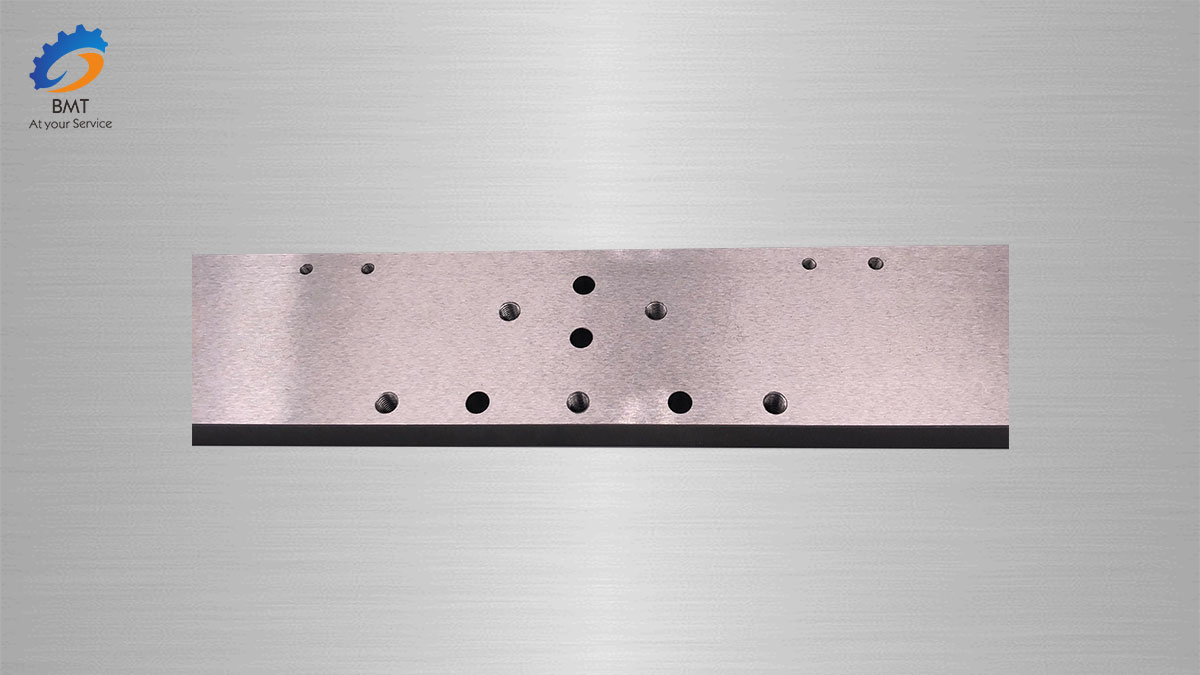

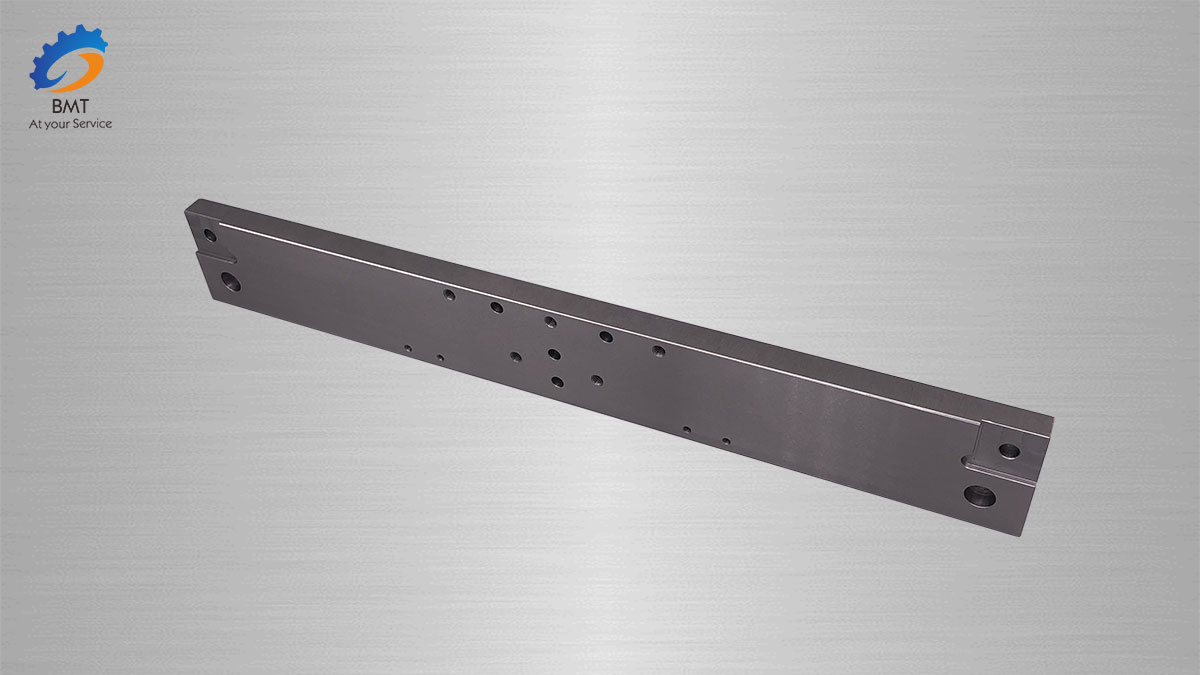

CNC Machining Clamping txuj ci

Machining Part Clamping:

Lub hauv paus ntsiab lus ntawm folding positioning installation

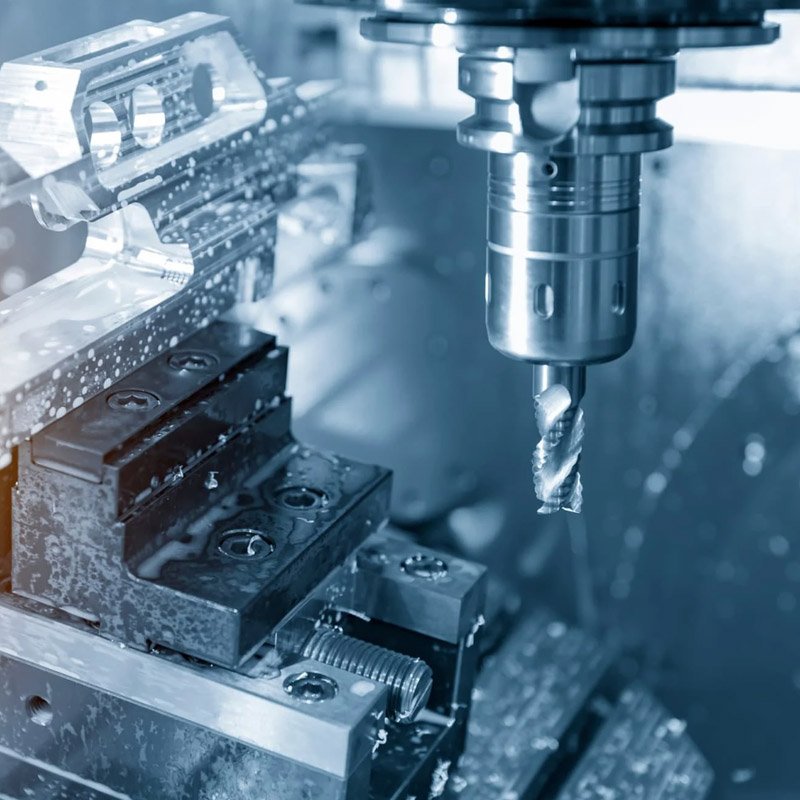

Thaum machining qhov chaw ntawm CNC tshuab cuab yeej, lub hauv paus ntsiab lus ntawm qhov chaw thiab installation yog xaiv ib tug tsim nyog positioning datum thiab clamping txoj kev npaj.Ua tib zoo mloog cov ntsiab lus hauv qab no thaum xaiv:

1. Sib zog ua kom muaj kev sib koom ua ke rau kev tsim, txheej txheem thiab kev ua haujlwm suav.

2. Txo cov sij hawm clamping tsawg, thiab ua txhua qhov chaw kom ua tiav tom qab muab tso rau thiab clamping ib zaug kom ntau li ntau tau.

3. Tsis txhob siv lub tshuab ua haujlwm hauv phau ntawv hloov kho cov txheej txheem los muab kev ua si tag nrho rau kev ua haujlwm ntawm CNC tshuab cuab yeej.

Lub hauv paus ntsiab lus ntawm folding thiab xaiv fixtures

Cov yam ntxwv ntawm CNC machining muab tso rau pem hauv ntej ob qho yooj yim yuav tsum tau rau lub fixture: ib tug yog los xyuas kom meej tias kev sib koom tes kev taw qhia ntawm lub fixture yog tsau nrog cov kev taw qhia ntawm lub tshuab cuab yeej;lwm qhov yog los tswj qhov kev sib raug zoo ntawm cov khoom thiab lub tshuab cuab yeej tswj qhov system.Tsis tas li ntawd, cov ntsiab lus hauv qab no yuav tsum tau xav txog:

1. Thaum lub batch ntawm qhov chaw tsis loj, modular fixtures, adjustable fixtures thiab lwm yam kev fixtures yuav tsum tau siv ntau npaum li sai tau los txo lub sij hawm npaj ntau lawm thiab txuag nqi ntau lawm.

2. Tsuas yog xav txog kev siv cov khoom siv tshwj xeeb thaum lub sijhawm tsim khoom loj, thiab siv zog kom muaj cov qauv yooj yim.

3. Kev thauj khoom thiab tshem tawm ntawm qhov chaw yuav tsum ceev, yooj yim thiab txhim khu kev qha kom txo lub sijhawm ntawm lub tshuab nres.

4. Cov khoom ntawm lub fixture yuav tsum tsis txhob cuam tshuam lub machining ntawm qhov chaw ntawm lub tshuab cuab yeej, uas yog, lub fixture yuav tsum tau qhib, thiab nws positioning thiab clamping mechanism yuav tsum tsis txhob cuam tshuam rau lub riam thaum lub sij hawm ua (xws li kev sib tsoo. , thiab lwm yam).

Machining yuam kev

Tus lej tswj machining yuam kev ntxiv yog tsim los ntawm kev ua haujlwm yuam kev kho, tshuab cuab yeej yuam kev tshuab, qhov chaw yuam kev ruaj khov, cov cuab yeej teeb tsa yuam kev thiab lwm yam yuam kev.

1. Programming yuam kev yog tsim los ntawm approximation yuam kev δ thiab rounding yuam kev.Lub approximation yuam kev δ yog tsim nyob rau hauv tus txheej txheem ntawm approximating ib tug uas tsis yog-cim nkhaus nrog ib tug ncaj kab ntu los yog ib ncig arc ntu, raws li qhia nyob rau hauv daim duab 1.43.Qhov yuam kev rounding yog qhov ua yuam kev uas tsim los ntawm kev sib npaug ntawm tus nqi sib koom ua ke rau tus nqi sib npaug ntawm cov mem tes sib npaug thaum ua cov ntaub ntawv.Pulse equivalent yog hais txog qhov kev hloov ntawm txhua chav tsev mem tes sib haum mus rau qhov kev sib koom ua ke axis.Ib txwm-precision CNC tshuab cuab yeej feem ntau muaj cov mem tes sib npaug ntawm 0.01mm;ntau cov cuab yeej CNC tshuab cuab yeej muaj cov mem tes sib npaug ntawm 0.005mm lossis 0.001mm, thiab lwm yam.

2. Qhov yuam kev ntawm lub tshuab cuab yeej yog tshwm sim los ntawm qhov yuam kev ntawm CNC system thiab cov khoom noj khoom haus.

3. Qhov teeb meem ntawm qhov chaw yog ib txwm tshwm sim thaum lub workpiece yog positioned ntawm lub fixture thiab fixture yog positioned ntawm lub tshuab cuab yeej.

4. Cov cuab yeej teeb tsa yuam kev yog tsim thaum txiav txim siab qhov chaw txheeb ze ntawm lub cuab yeej thiab cov khoom ua haujlwm.