CNC Machining Processing cov lus nug tiag

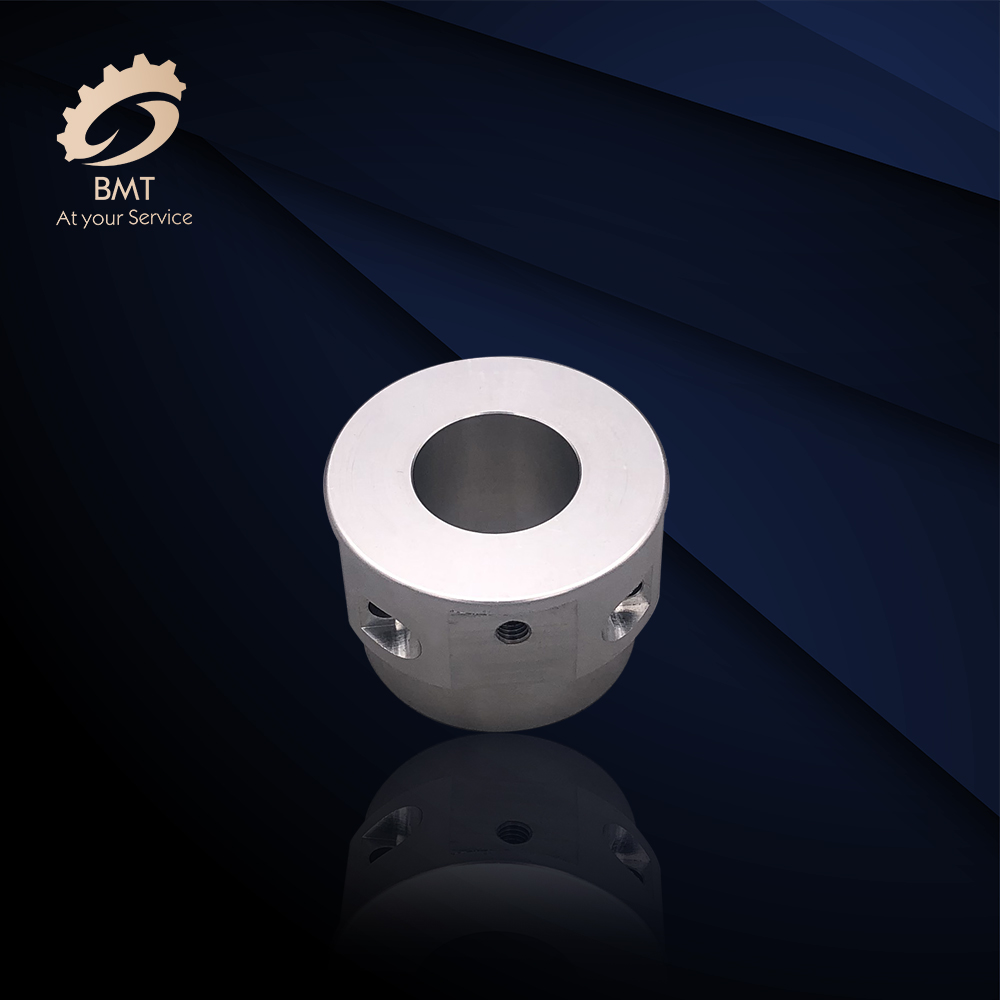

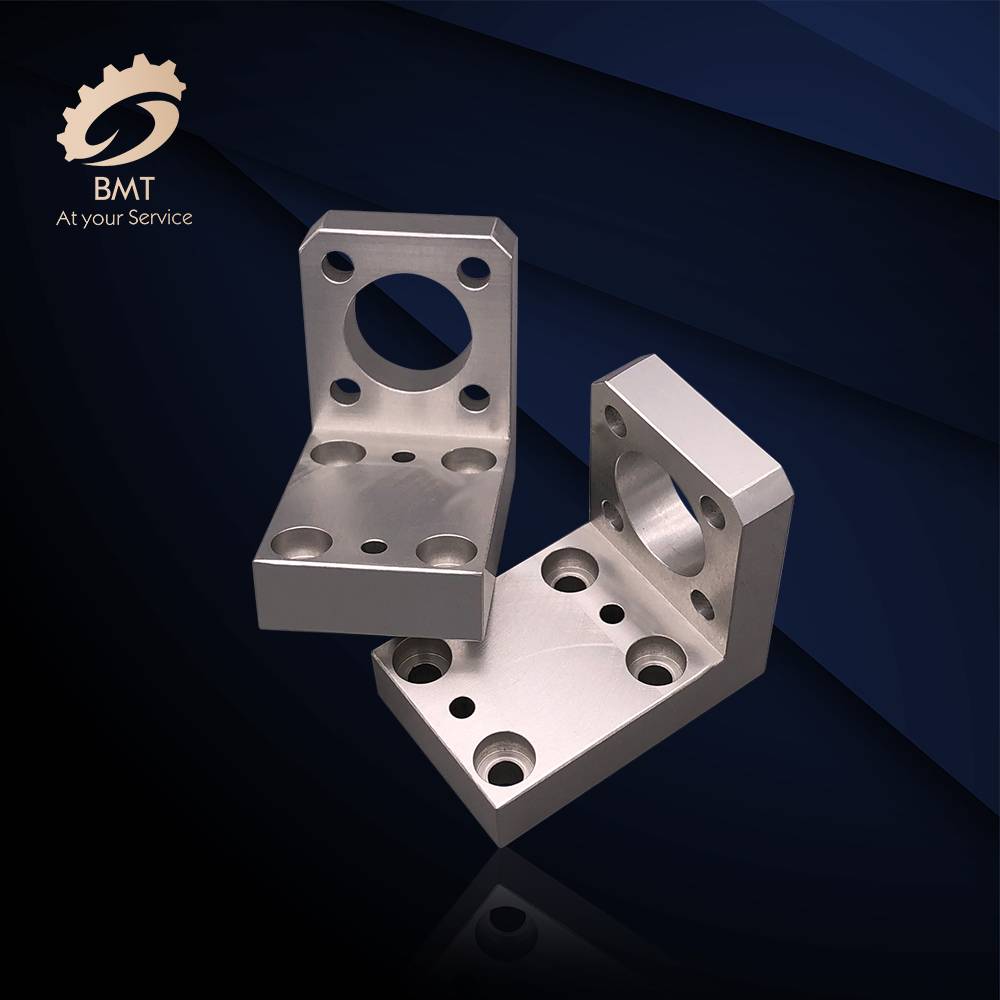

Precision machining tuaj yeem nqa cov txheej txheem tsim khoom mus rau qib tom ntej.Nws tuaj yeem ua haujlwm zoo rau kev ua haujlwm zoo, txo lub sijhawm hloov pauv, thiab txiav cov nqi tsim khoom.Leej twg paub qhov no zoo dua li ib qho ntawm Tuam Tshoj tus loj CNC tig thiab Milling Cheebtsam manufacturers nrog 15 xyoo ntawm kev paub nyob rau hauv nws txoj siv?BMT tau muab qhov tshwj xeeb precision qhov chaw rau kev lag luam txij li thaum.

Mechanical processing vibration tiv thaiv thiab tswj:

Txhawm rau tshem tawm lossis ua kom tsis muaj zog ntawm cov xwm txheej uas tsim kev co machining;Txhawm rau txhim kho cov yam ntxwv zoo ntawm cov txheej txheem los txhim kho kev ruaj ntseg ntawm cov txheej txheem siv ntau yam kev co damping li

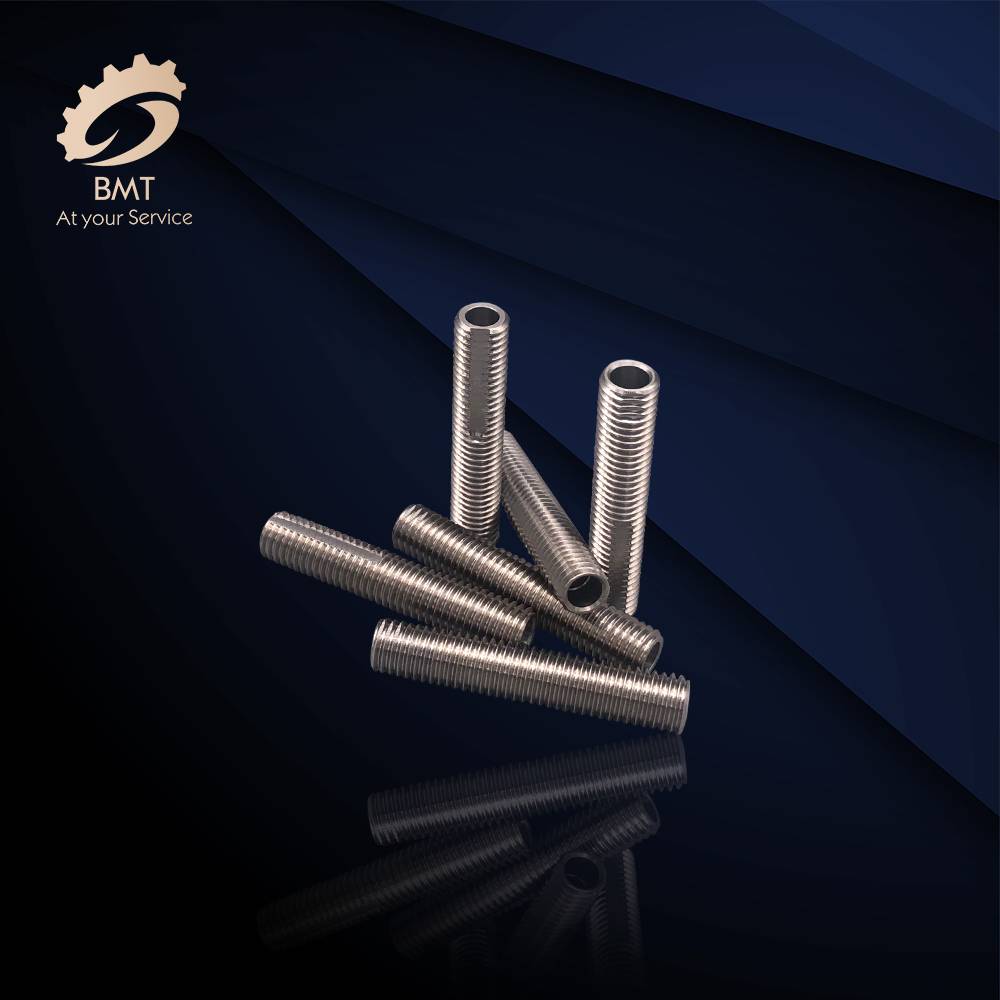

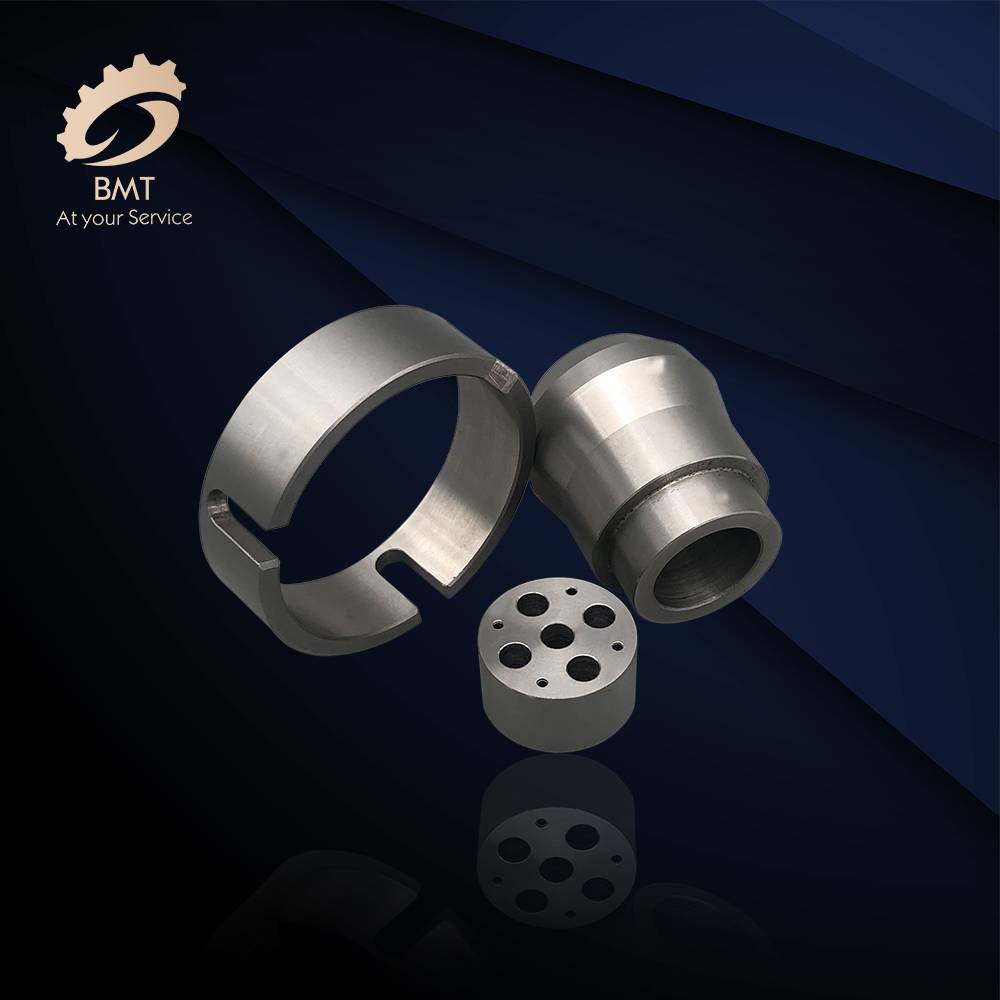

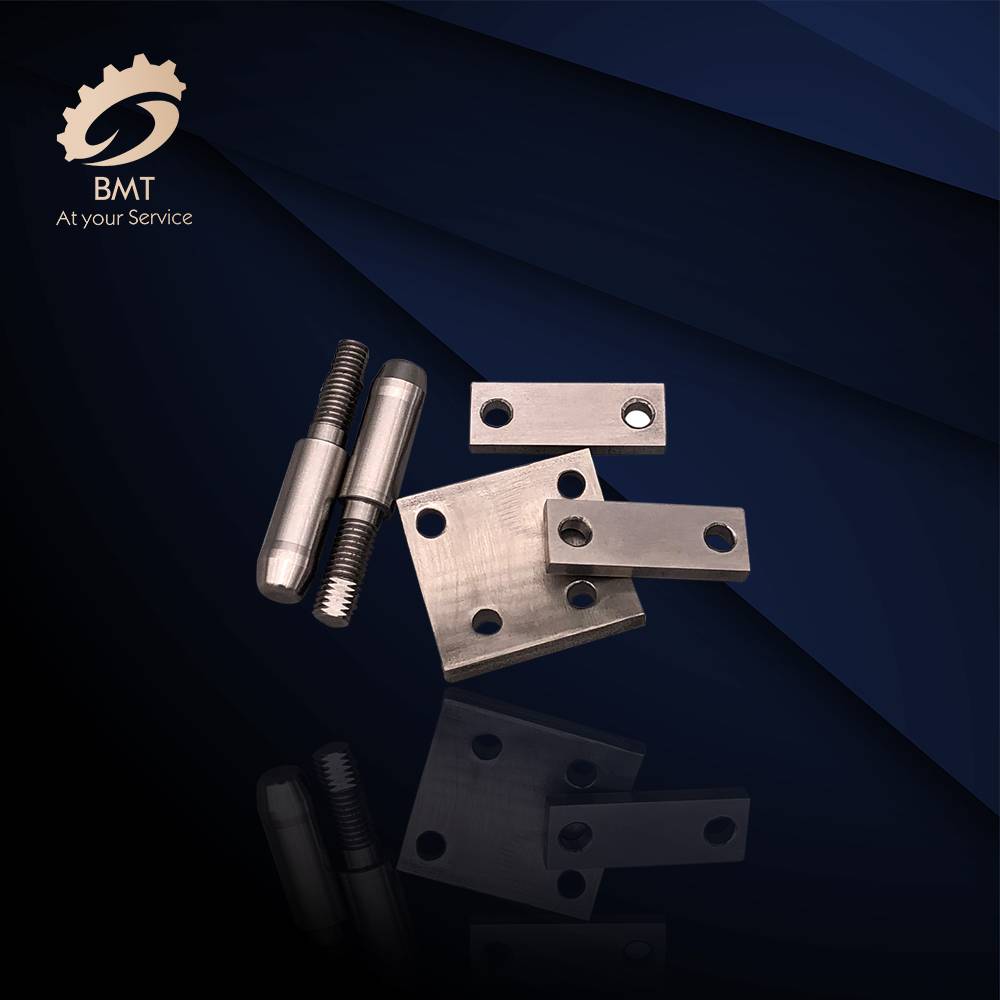

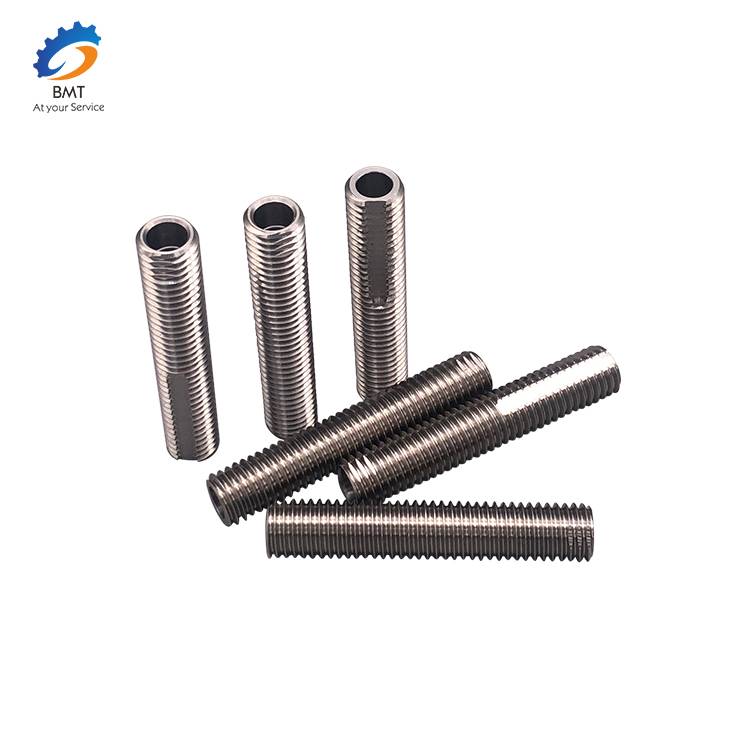

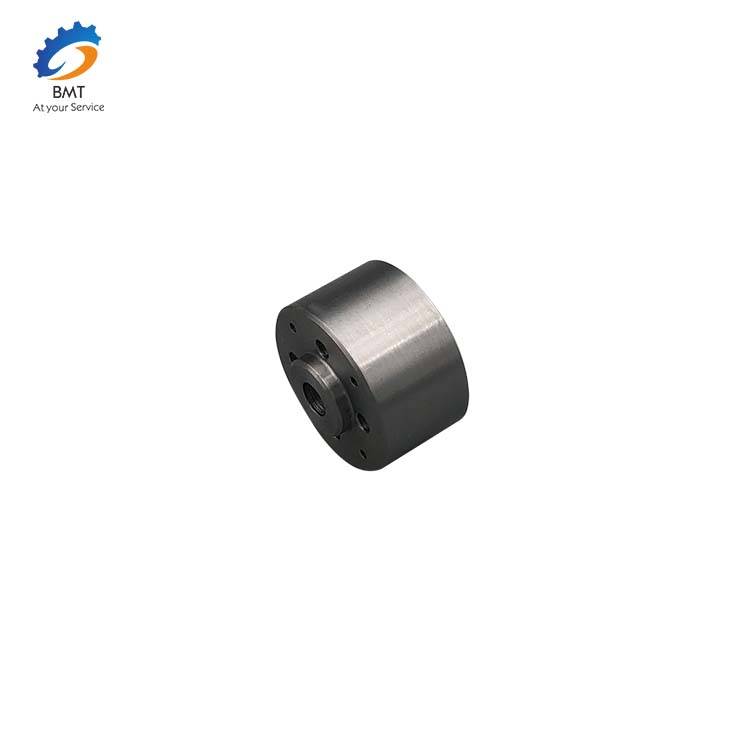

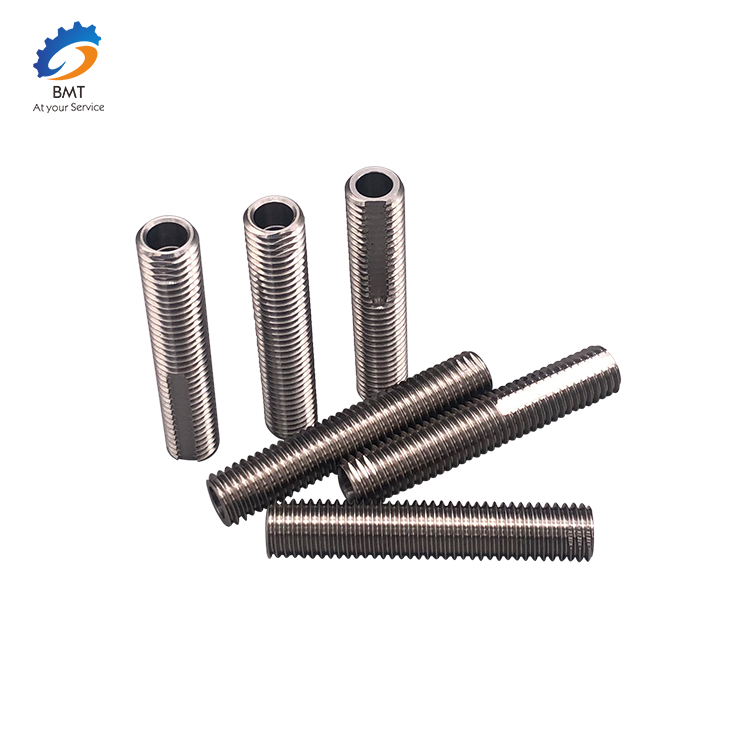

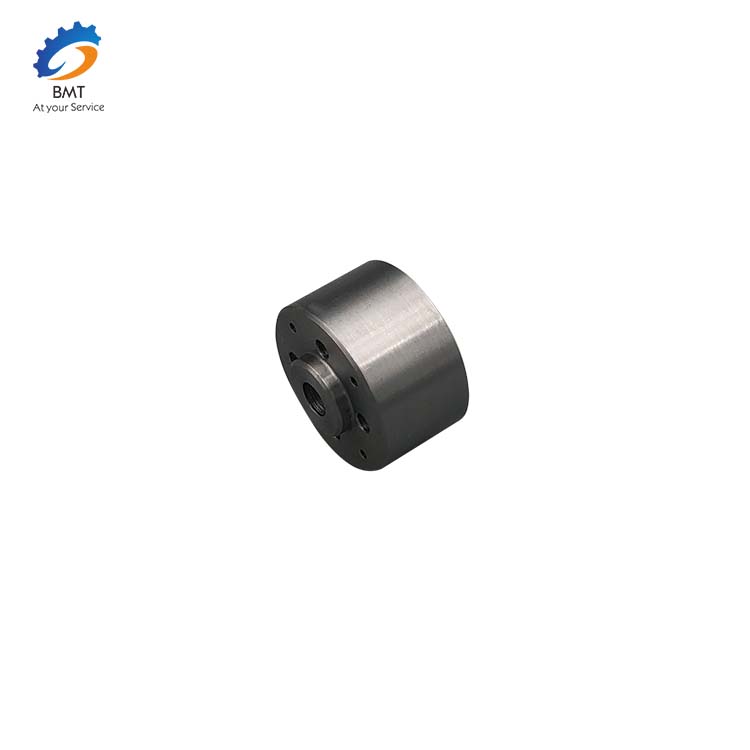

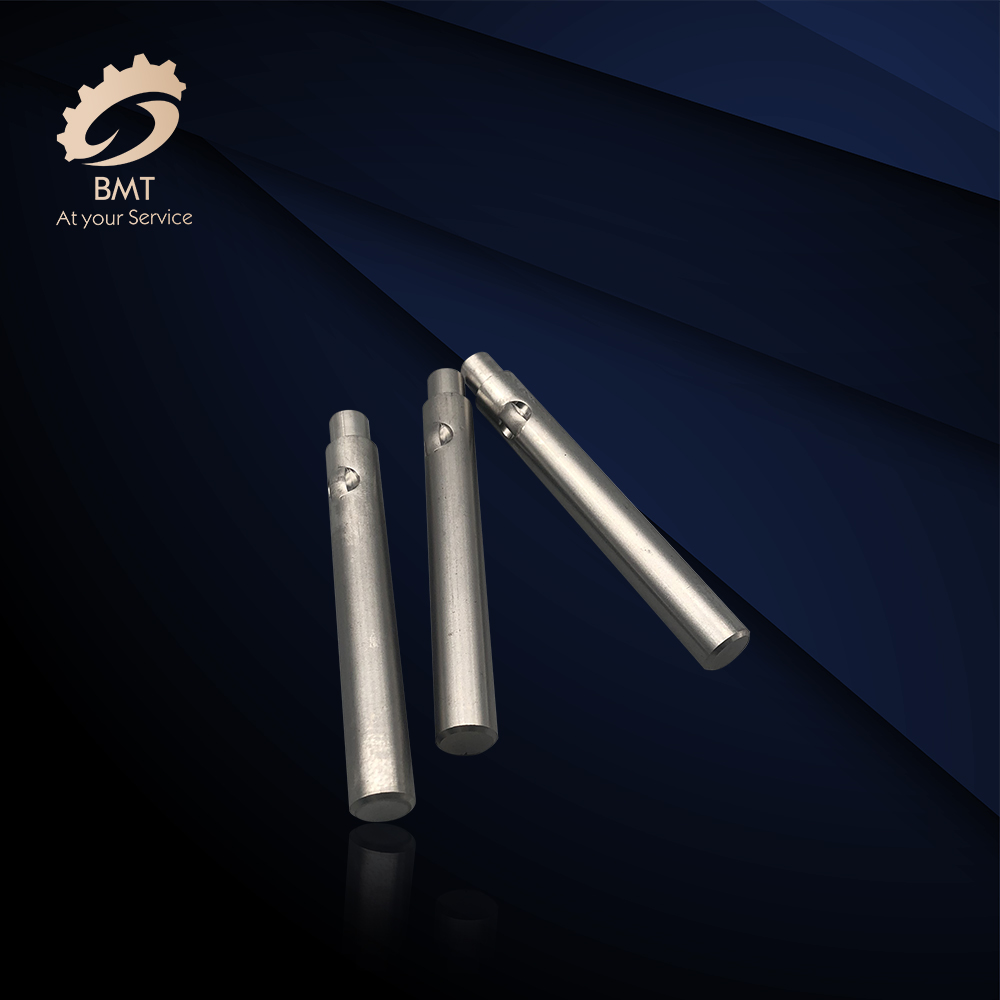

Product Description

Vim li cas thiaj xaiv peb CNC Machined Parts?

Rough benchmark xaiv txoj cai?Lub hauv paus ntsiab lus ntawm kev xaiv tus qauv zoo?

Crude benchmark:

1. Lub hauv paus ntsiab lus ntawm kev ua kom muaj kev sib koom ua haujlwm;

2. Lub hauv paus ntsiab lus ntawm kev ua kom ntseeg tau qhov tsim nyog faib ntawm machining pub ntawm machining nto;

3. Lub hauv paus ntsiab lus ntawm kev yooj yim workpiece clamping;

4. Lub hauv paus ntsiab lus hais tias coarse datum yuav tsum tsis txhob rov qab siv nyob rau hauv dav dav

Cov txiaj ntsig zoo:

1. Txoj cai ntawm datum sib tshooj;

2. Unified benchmark txoj cai;

3. Kev sib nrig sib benchmark txoj cai;

4. Kev pabcuam tus kheej lub hauv paus ntsiab lus;

5. Yooj yim rau clamp txoj cai.

Dab tsi yog cov ntsiab lus ntawm cov txheej txheem ua ntu zus?

a) Thawj txheej txheem datum theem, thiab tom qab ntawd txheej txheem lwm qhov chaw;

b) Nyob rau hauv ib nrab ntawm cov rooj plaub, qhov saum npoo yog ua ntej, thiab tom qab ntawd lub qhov yog ua tiav;

c) Lub ntsiab nto yog ua ntej, thiab qhov chaw thib ob yog ua tiav tom qab;

d) Npaj cov txheej txheem roughing ua ntej, tom qab ntawd ua tiav cov txheej txheem.

Yuav faib cov txheej txheem ua li cas?Dab tsi yog cov txiaj ntsig ntawm kev faib cov txheej txheem ua tiav?

Processing theem faib:

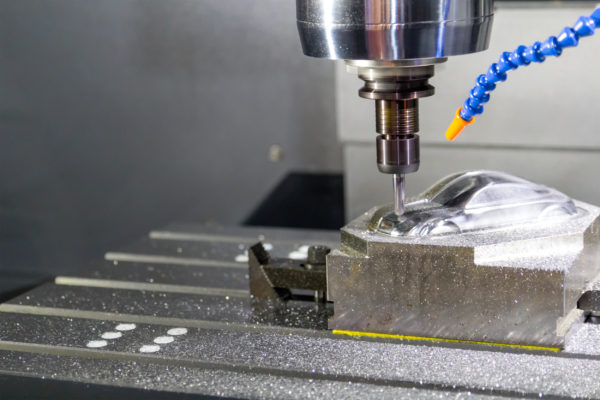

1) Rough machining theem

2) Semi-finishing theem

3) Kev ua tiav theem

4) Precision finishing theem

Nws tuaj yeem ua kom lub sijhawm txaus los tshem tawm cov thermal deformation thiab cov kev ntxhov siab uas tshwm sim los ntawm kev ua haujlwm ntxhib, txhawm rau txhim kho qhov tseeb ntawm kev ua haujlwm tom ntej.Tsis tas li ntawd, nyob rau hauv cov txheej txheem ntxhib pom qhov tsis xws luag tsis tas yuav tsum tau ua tiav hauv theem tom ntej ntawm kev ua, kom tsis txhob pov tseg.Tsis tas li ntawd, kev siv cov cuab yeej tsim nyog, cov cuab yeej siv tshuab tsis tshua muaj siab rau cov cuab yeej siv tshuab ua kom zoo rau kev ua tiav, txhawm rau tswj cov qib precision ntawm cov cuab yeej siv tshuab;Kev tsim nyog tsim nyog ntawm tib neeg cov peev txheej, cov neeg ua haujlwm siab ua haujlwm tshwj xeeb hauv kev ua tiav cov txheej txheem ultra-precision, uas yog qhov tseem ceeb heev los xyuas kom meej cov khoom zoo, txhim kho qib ntawm kev siv tshuab.