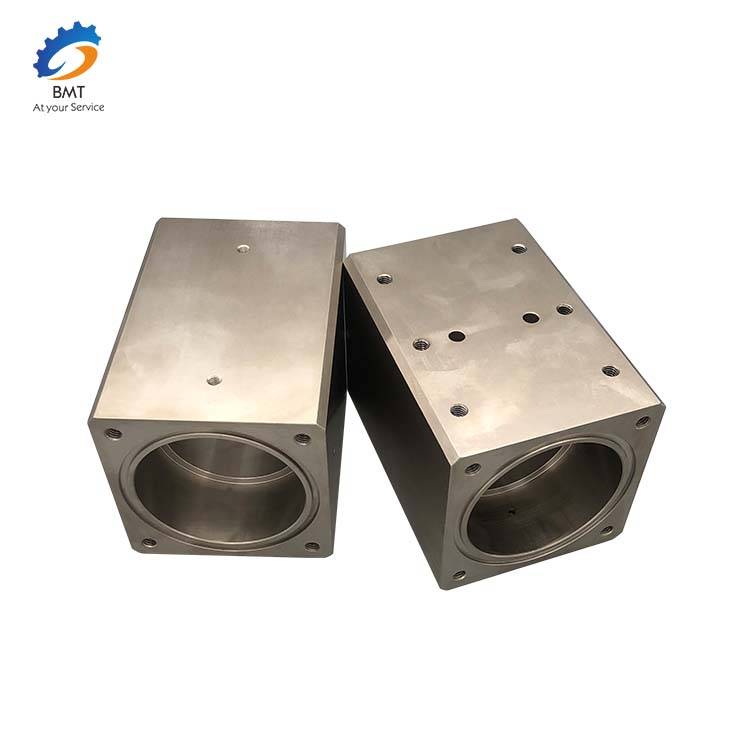

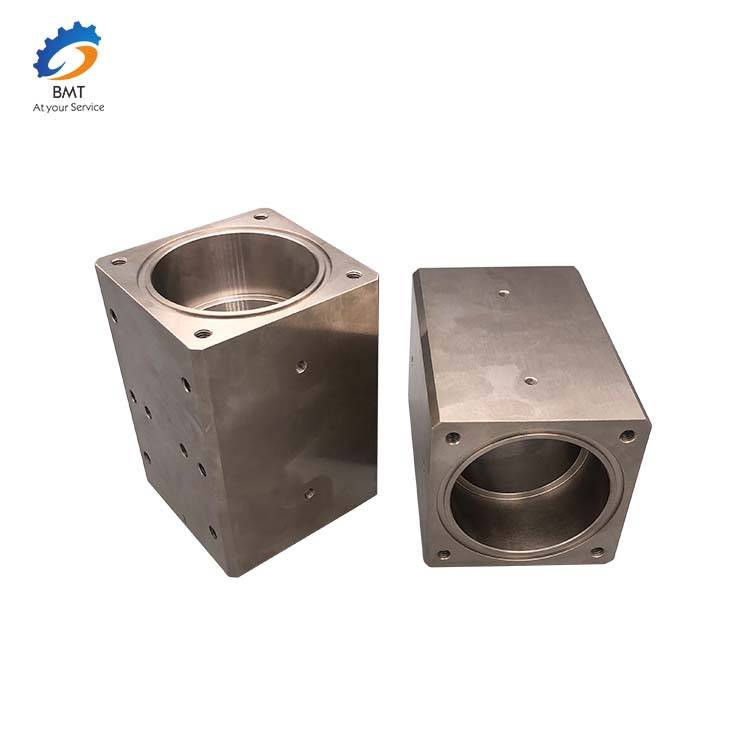

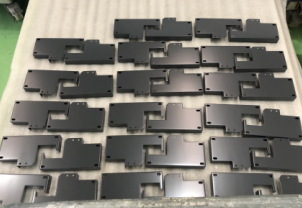

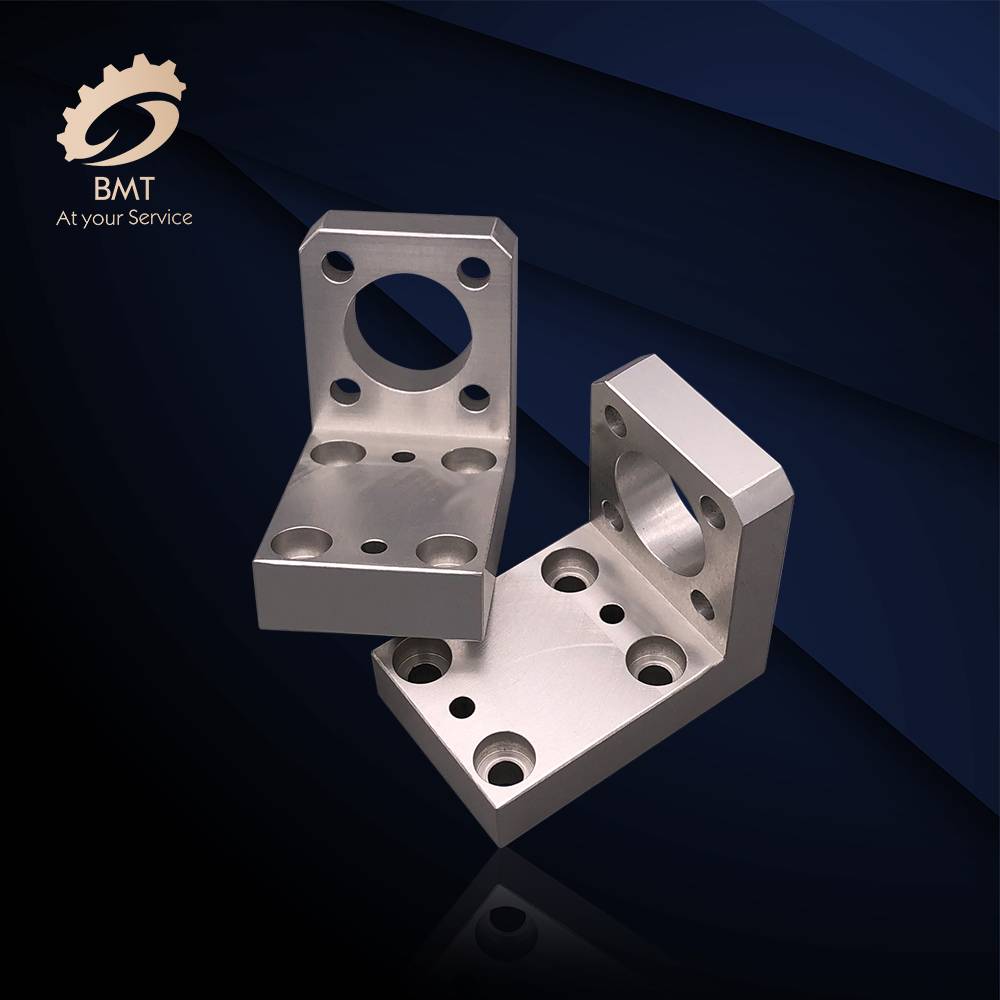

BMT CNC Machining Nto Kho Kho

Qee lub sij hawm, Cov neeg siv khoom xaiv cov kev kho mob saum npoo hlau tom qab machining ntawm BMT los txhim kho qhov zoo ntawm qhov chaw, kom tau qhov chaw du, thiab ncav cuag corrosion, thiab lwm yam. Nrog rau ntau tshaj 10 xyoo kev paub nrog CNC Precision Machining Parts thiab kawm los ntawm cov neeg siv khoom, peb cov neeg muas zaub. Feem ntau xaiv Oxide Blacking, Polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Thaum tshav kub kub kho, hmoov Coated, thiab lwm yam. Qhov txawv ntawm cov kev kho deg no yog dab tsi?

| Electroplating | Ib txheej txheem ntawm kev siv hluav taws xob tam sim no los txo cov hlau yaj cations kom lawv tsim cov hlau coherent nyias txheej ntawm cov electrode, hloov cov khoom ntawm cov hlau nto los yog tsim cov thickness rau undersized qhov chaw. |

|

| Polishing | Cov txheej txheem ntawm kev txhuam qhov chaw ntawm qhov chaw los yog siv cov tshuaj ua haujlwm los tsim qhov chaw du thiab ci ntsa iab, ua rau saum npoo tau txais qhov tseem ceeb ntawm kev xav lossis txo qhov cuam tshuam ntawm qee cov ntaub ntawv. |

|

| Kev pleev xim | Hais txog kev hloov kho qhov chaw tiav, cov xim pleev xim, xim xim, lossis xim rau cov khoom saum npoo raws li cov xim tiv thaiv, thiab tuaj yeem ua rau cov hlau lossis cov hlau tsis yog hlau CNC machined Cheebtsam ntawm txhua daim duab, feem ntau siv rau txhuas, stainless hlau thiab steel alloy qhov chaw.Lub hom phiaj yog txhawm rau txhim kho qhov zoo nkauj thiab tiv thaiv corrosion lossis oxidation. |

|

| Passivation | Ib txoj kev kho tshuaj lom neeg ntawm cov hlau thiab stainless hlau, kom tshem tawm cov kab mob ferrous los yog siv lub teeb lub tsho tiv thaiv los tsim lub plhaub rau kev txhim kho corrosion los yog txo cov tshuaj reactivity. |

|

| Hmoov txheej | Kev ua haujlwm zoo thiab kho kom zoo nkauj tiav, uas yog siv los ua cov hmoov dawb-ntws, qhuav hmoov, ua haujlwm electrostatically thiab tom qab ntawd kho hauv qab cua sov, los tsim cov tawv tiav uas yog tawv dua li cov xim pleev xim.Cov ntawv thov tseem ceeb suav nrog cov khoom siv hauv tsev, aluminium extrusion, nruas hardware, tsheb, maus taus, thiab tsheb kauj vab qhov chaw. |

|

| Anodizing | Cov txheej txheem electrolytic passivation ntawm kev tsim cov txheej txheej nyias ntawm aluminium oxide rau sab nrauv ntawm aluminium CNC machined qhov chaw kom cov thickness ntawm lub ntuj oxide txheej thiab tiv thaiv cov hlau, raws li cov txheej txheem muaj ntau dua corrosion thiab abrasion tsis kam tshaj txhuas. |

|

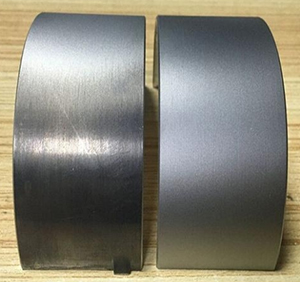

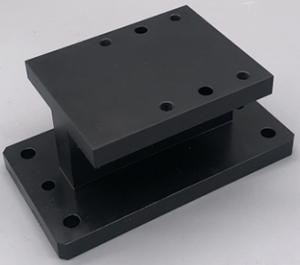

| Dub oxide | Cov txheej txheem tshuaj ntawm kev tsim cov txheej txheem xim dub ntawm cov hlau tsis muaj steel, tooj liab thiab tooj liab raws li alloys, zinc, hmoov hlau, nyiaj solder, thiab ferrous cov ntaub ntawv, los txhim kho corrosion kuj thiab txo lub teeb pom kev zoo. |  |

| Abrasive blasting / Sandblasting | Cov txheej txheem los yog kev khiav hauj lwm ntawm propelling ib tug kwj ntawm cov khoom abrasive muaj li ntawm high-ceev xuab zeb-qhov loj me hais tawm tsam cov hlau nto nyob rau hauv siab siab nrog blast cov cuab yeej xws li cua siab system, kom tshem tawm cov kab mob deg, huv si hlau los yog ua kom ib tug zoo nkauj, ces hloov lub smoothness los yog roughness ntawm nto. |

|

| Phosphating | Cov txheej txheem tshuaj rau kev kho qhov chaw ntawm cov hlau, qhov uas tsis tshua muaj cov txheej txheem hlau-phosphate yog tsim los ntawm cov khoom siv hauv paus.Cov khaubncaws sab nraud povtseg tsim yog ntxeem tau, absorbent thiab haum raws li ib tug hloov dua siab tshiab txheej rau cov hmoov txheej tom ntej tsis muaj kev kho mob ntxiv. |  |

BMT kuj muab kev sib tsoo, kev lag luam etching, thiab ntau cov kev cai hlau tiav rau kev nthuav tawm cov txiaj ntsig zoo tshaj plaws ntawm koj txoj haujlwm.Tsuas yog qhia peb yam koj xav tau thiab peb yuav saib xyuas tus so!

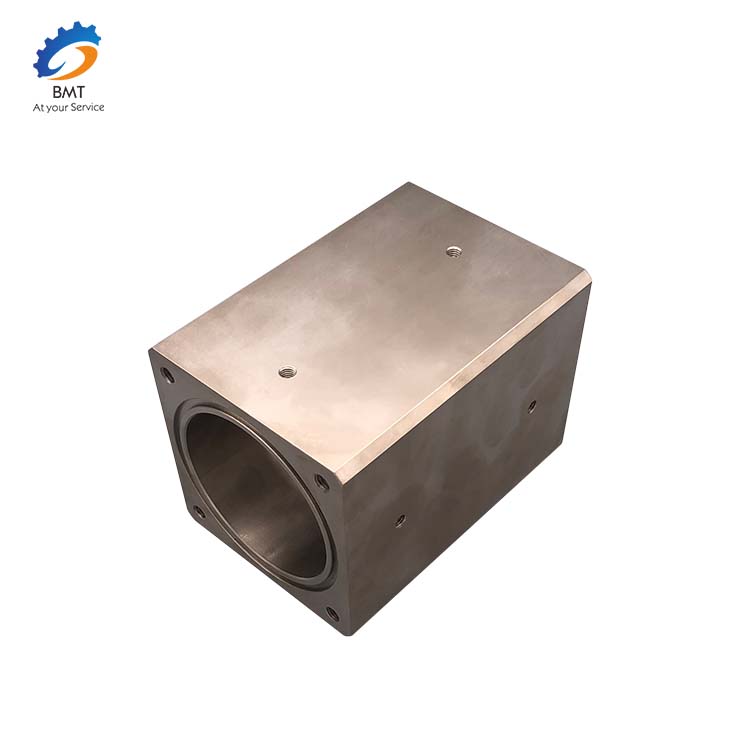

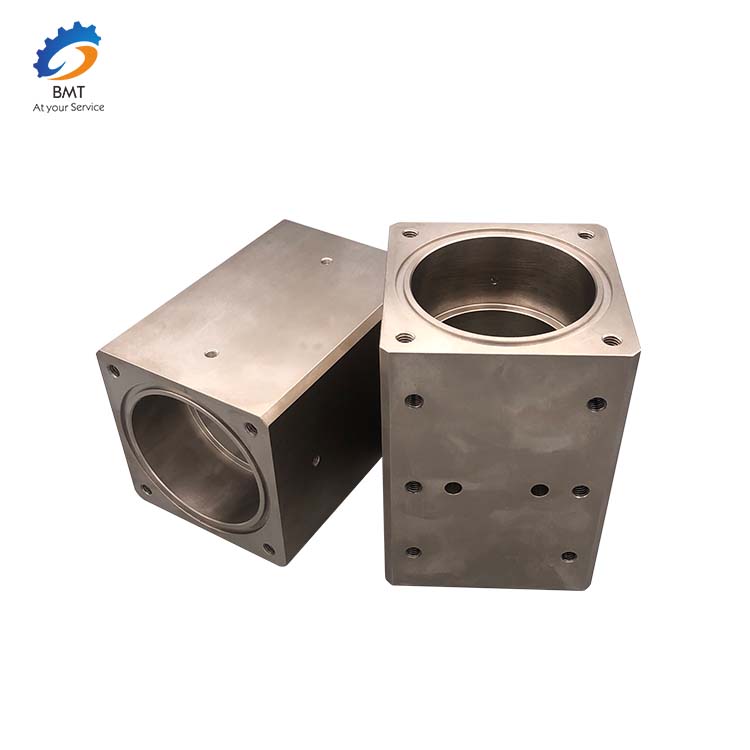

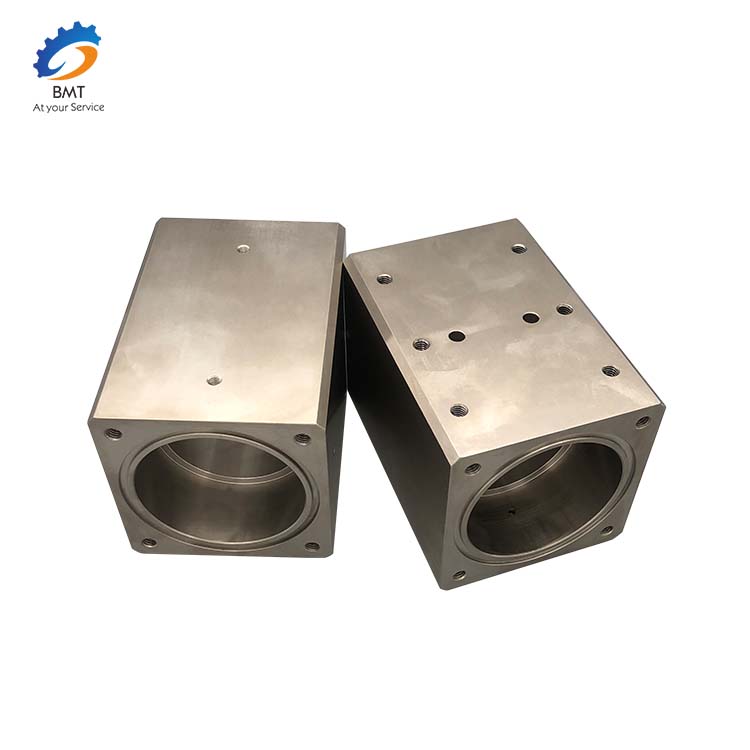

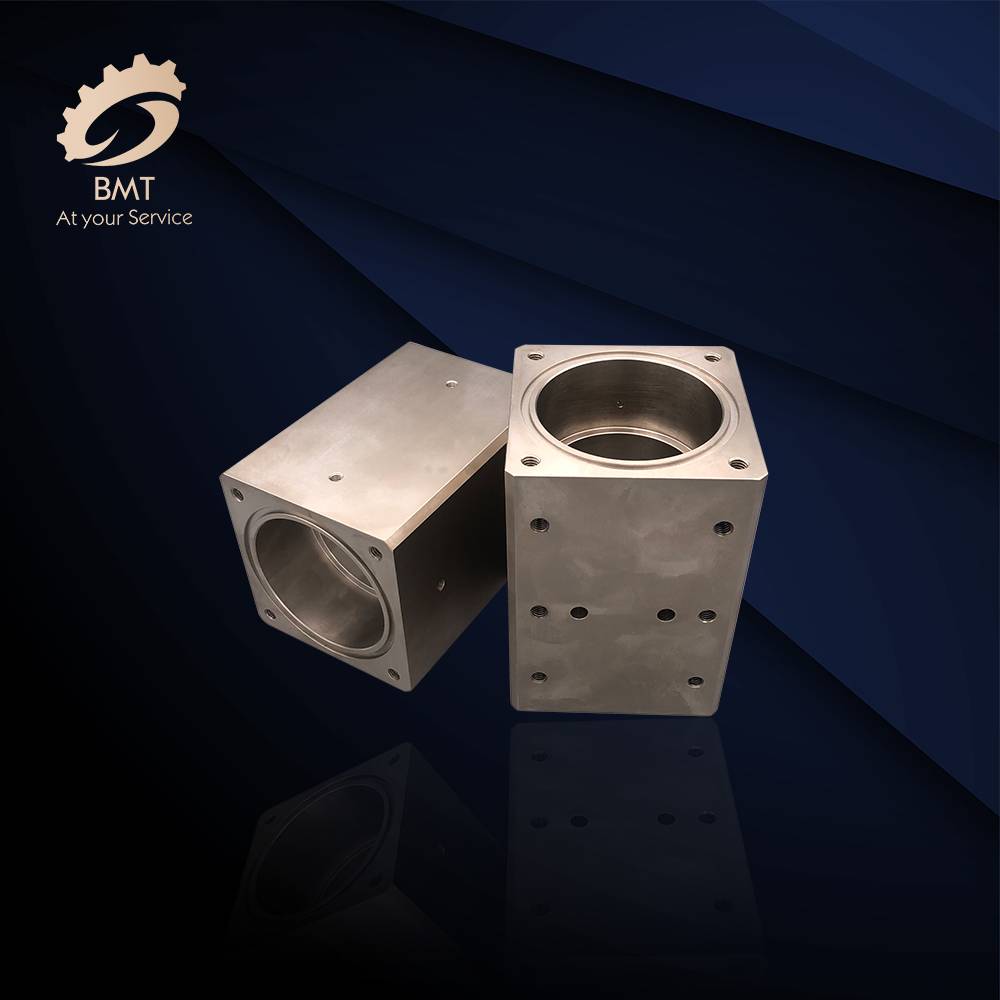

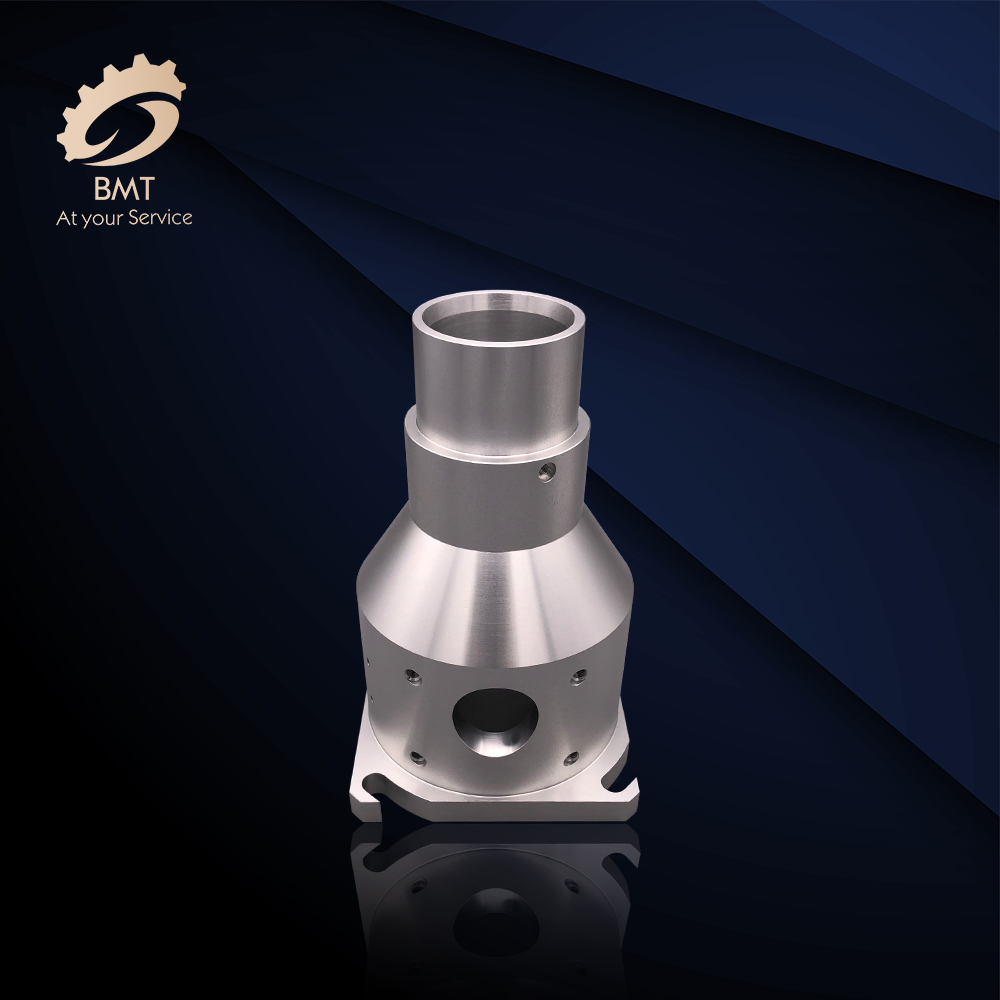

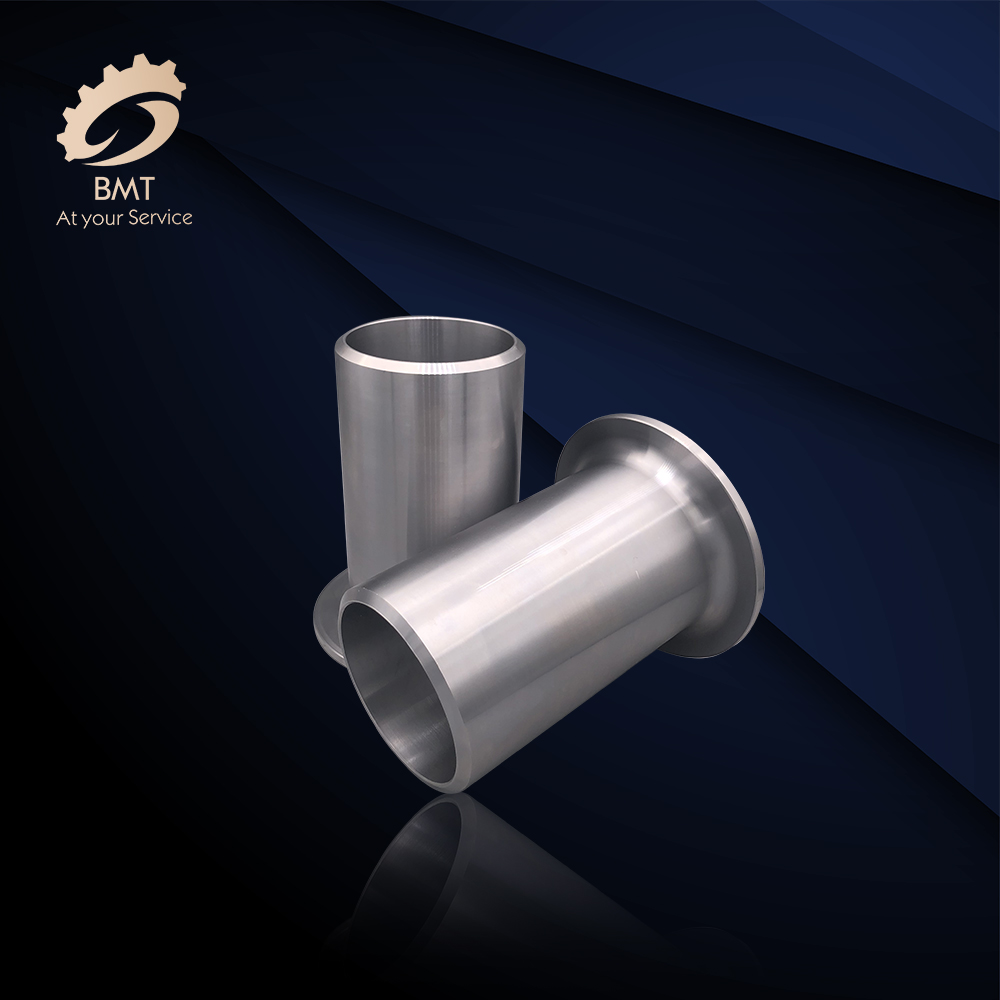

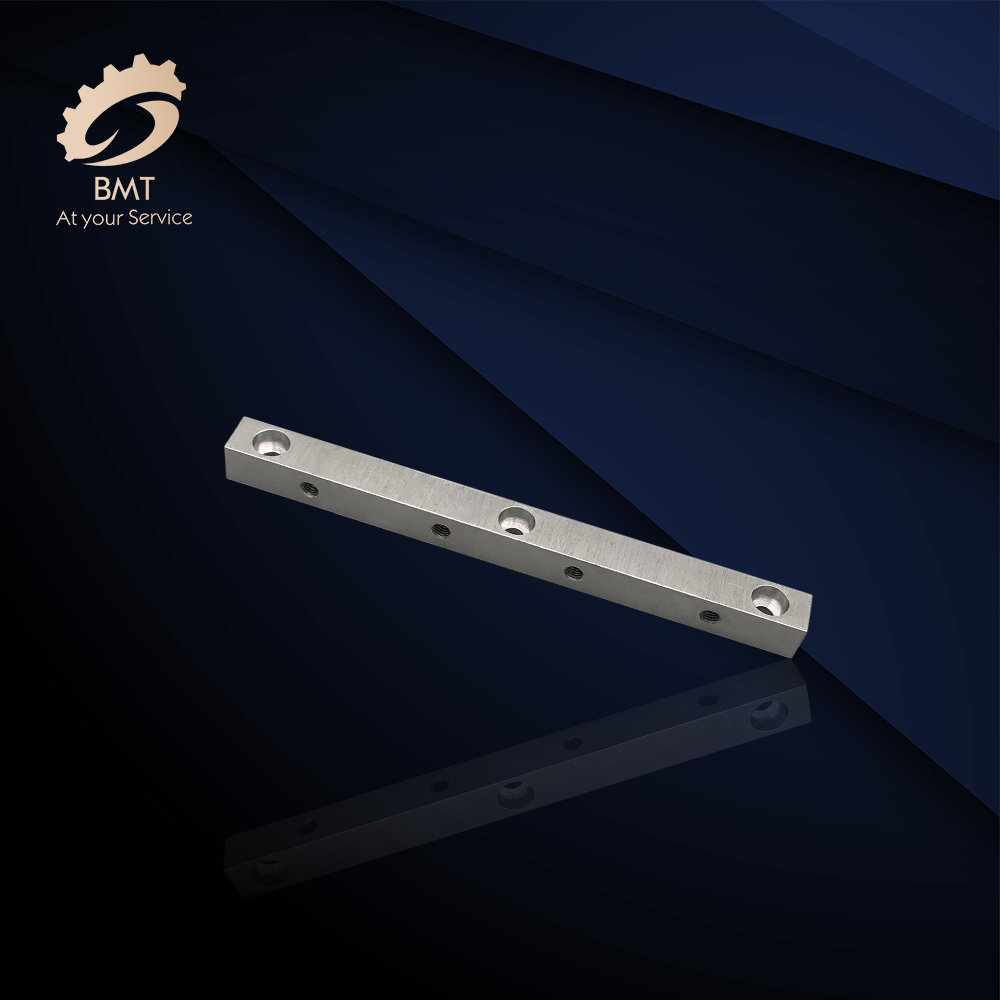

Product Description