Hauv ntiaj teb nokev tsim khoom, muaj peev xwm tshuab qhov chaw los ntawm ntau yam khoom siv yog qhov tseem ceeb rau kev tsim cov khoom zoo. Los ntawm cov hlau mus rau cov khoom sib xyaw, qhov kev thov rau precision machining ntawm cov ntaub ntawv sib txawv tau ua rau muaj kev nce qib tseem ceeb hauv kev siv tshuab machining. Ib qho ntawm cov teeb meem tseem ceeb hauv kev ua cov khoom sib txawv yog qhov sib txawv ntawm txhua yam khoom. Cov hlau xws li txhuas, hlau, thiab titanium xav tau cov txheej txheem sib txawv vim lawv cov tawv tawv, ductility, thiab thermal conductivity. Ib yam li ntawd, cov khoom sib xyaw zoo li carbon fiber thiab fiberglass nthuav qhia lawv tus kheej cov teeb meem nrog lawv cov xwm txheej thiab nyiam delaminate thaum lub sijhawm ua haujlwm.

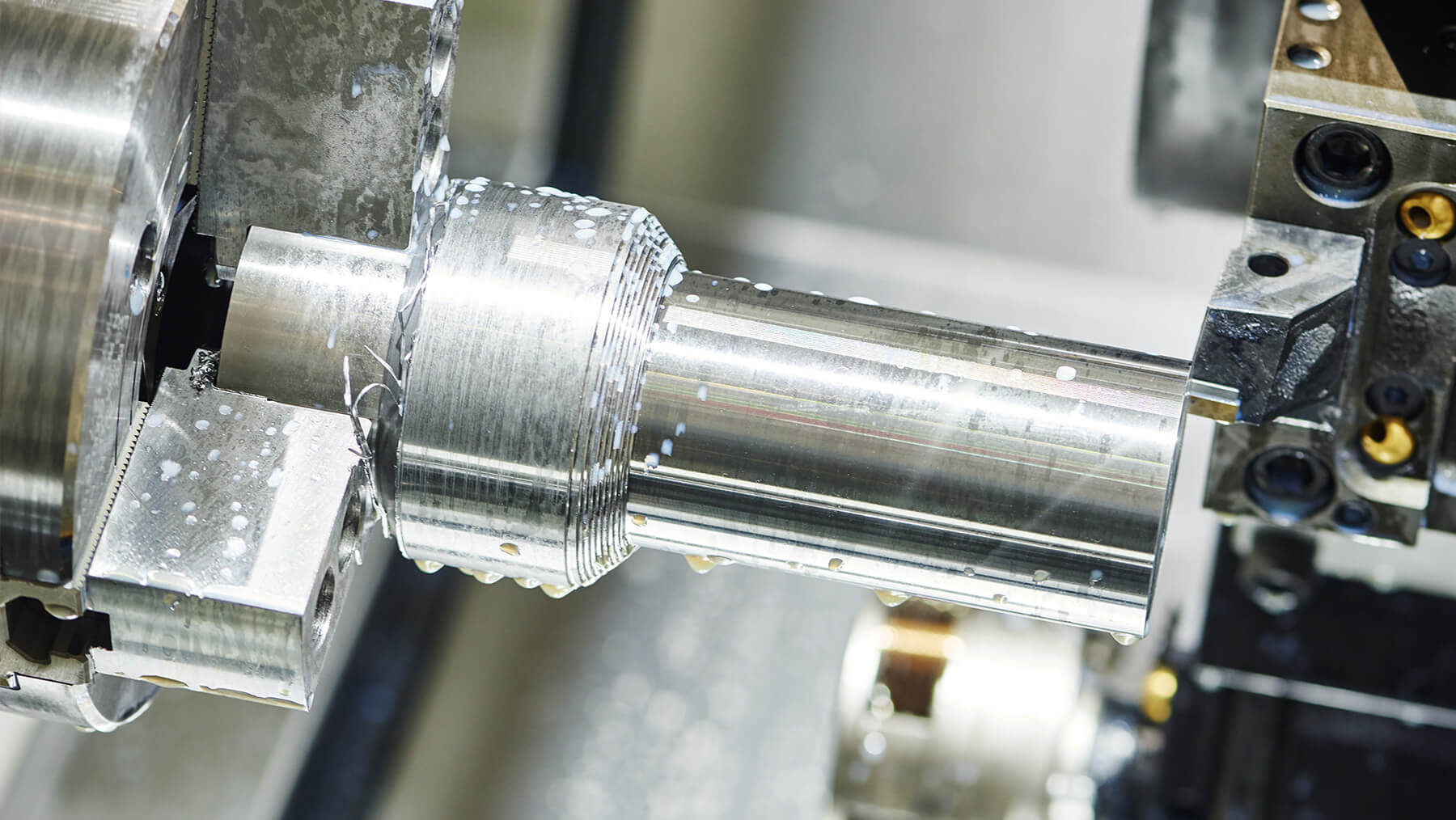

Txhawm rau daws cov teeb meem no, cov tuam txhab lag luam tau nqis peev hauv cov thev naus laus zis thev naus laus zis uas tuaj yeem tswj hwm ntau yam khoom siv nrog qhov tseeb thiab ua haujlwm tau zoo. Ib tug xws li technology yogMulti-axis CNC machining, uas tso cai rau cov geometry complex thiab nruj tolerances ua tiav nyob rau hauv ntau yam ntaub ntawv. Los ntawm kev siv cov cuab yeej txiav qib siab thiab cov tswv yim zoo, CNC machining tau dhau los ua ntau yam kev daws teeb meem rau machining qhov chaw los ntawm cov hlau, cov khoom sib xyaw, thiab cov khoom sib txawv xws li ceramics thiab super alloys. Ntxiv nrog rau CNC machining, kev nce qib hauv cov cuab yeej txiav cov cuab yeej kuj tau ua lub luag haujlwm tseem ceeb hauv kev ua cov khoom sib txawv. High-speed steel (HSS) thiab cov cuab yeej carbide tau yog cov kev xaiv ib txwm siv rau kev ua cov hlau, tab sis qhov nce ntawm cov khoom siv ceramic thiab pob zeb diamond-coated tau nthuav dav lub peev xwm ntawm machining kom muaj cov ntaub ntawv nyuaj thiab abrasive.

Cov no advancedcov cuab yeej txiavmuab kev txhim kho hnav tsis kam thiab thermal stability, tso cai rau kev txiav nrawm dua thiab lub neej ntev dua thaum siv cov khoom siv xws li Inconel, hardened steel, thiab carbon composites. Tsis tas li ntawd, kev sib koom ua ke ntawm kev tsim khoom ntxiv nrog cov txheej txheem machining ib txwm tau qhib qhov muaj peev xwm tshiab rau kev tsim khoom los ntawm ntau yam khoom siv. Hybrid manufacturing systems, uas ua ke 3D luam ntawv nrog CNC machining, tau enabled zus tau tej cov complex, high-kev ua tau zoo qhov chaw nrog tailored khoom zog. Txoj hauv kev no tau muaj txiaj ntsig tshwj xeeb rau kev lag luam xws li aerospace thiab automotive, qhov twg lub teeb yuag, cov ntaub ntawv muaj zog muaj zog heev.

Kev nce qib hauv machining thev naus laus zis rau cov khoom sib txawv kuj tau raug tsav los ntawm kev xav tau ntau ntxiv rau kev tsim khoom lag luam. Nrog rau kev tsom mus rau txo cov khoom pov tseg thiab kev siv hluav taws xob, cov txheej txheem machining tau hloov zuj zus los ua kom muaj txiaj ntsig zoo thiab ib puag ncig zoo. Piv txwv li, kev siv cov tshuab ua kom txias txias thiab qhov tsawg kawg nkaus kom muaj nuj nqis lubrication tau txhim kho nti khiav tawm thiab txo qis kev noj cov kua dej, ua rau muaj kev ruaj khov dua.txheej txheem machining. Tsis tas li ntawd, kev siv cov thev naus laus zis thev naus laus zis, xws li simulation software thiab lub sijhawm saib xyuas lub sijhawm, tau txhim kho qhov kev kwv yees thiab kev tswj xyuas cov txheej txheem machining rau cov khoom sib txawv. Los ntawm kev simulating machining ntawm ntau yam ntaub ntawv, manufacturers tuaj yeem ua kom zoo dua cov cuab yeej txoj kev tswv yim thiab txiav cov kev txwv kom txo cov cuab yeej hnav thiab ua kom muaj txiaj ntsig zoo.

Kev saib xyuas lub sijhawm tiag tiag muab kev nkag siab zoo rau cov cuab yeej thiab cov txheej txheem kev ruaj ntseg, tso cai rau kev saib xyuas thiab kev ruaj ntseg zoo thaum lub sijhawm ua haujlwm machining. Hauv kev xaus, kev nce qib hauv machining thev naus laus zis rau cov khoom sib txawv tau hloov pauv kev lag luam tsim khoom, ua rau kev tsim cov khoom zoo nrog ntau dua.precision, efficiency, thiab sustainability. Nrog rau kev txhim kho txuas ntxiv ntawm ntau lub axis CNC machining, cov cuab yeej txiav siab heev, kev tsim khoom sib txuas, thiab cov thev naus laus zis tsim digital, cov tuam txhab tsim khoom zoo kom tau raws li qhov xav tau ntawm cov khoom siv los ntawm ntau yam khoom siv. Raws li kev lag luam txuas ntxiv mus, kev sib koom ua ke ntawm cov ntaub ntawv tshiab thiab thev naus laus zis yuav nthuav dav ntxiv rau kev siv tshuab, tsav tsheb tshiab thiab kev nce qib hauv kev tsim khoom.

Post lub sij hawm: May-06-2024