Pulse thiab Nruam Wave Hom

Ib qho tseem ceeb ntawm kev kho qhov muag micromachining yog kev hloov ntawm tshav kub mus rau thaj tsam ntawm substrate nyob ib sab ntawm cov khoom siv micro-machined. Lasers tuaj yeem ua haujlwm hauv hom mem tes lossis hom nthwv dej tsis tu ncua. Nyob rau hauv kev nruam nthwv dej hom, lub laser tso zis ntau yam tas li nyob rau lub sij hawm.

Nyob rau hauv hom mem tes, lub laser tso zis yog concentrated nyob rau hauv me me pulses. Pulsed hom laser li muab pulses thiab me me mem tes ntev nrog lub zog txaus rau micromachining ntawm cov khoom muab. Lub sijhawm me me pulse txo qis cov cua sov mus rau cov khoom nyob ib puag ncig. Laser pulses tuaj yeem sib txawv ntawm qhov ntev ntawm milliseconds mus rau femtoseconds.

Lub zog siab tshaj plaws yog cuam tshuam nrog lub sijhawm ntawm lub laser mem tes, yog li cov lasers pulsed tuaj yeem ua tiav ntau dua peaks tshaj qhov nruam tsis tu ncua.

Laser ua feem ntau muaj kev sib cuam tshuam uas ua rau ablation ntawm cov khoom siv substrate. Lub zog hloov pauv uas tshwm sim nyob ntawm cov khoom siv thiab cov khoom siv laser. Laser cov yam ntxwv uas cuam tshuam rau cov yam ntxwv muaj xws li lub zog siab tshaj plaws, mem tes dav, thiab emission wavelength. Kev txiav txim siab ntawm cov khoom yog seb nws puas tuaj yeem nqus tau lub zog laser los ntawm cov txheej txheem thermal thiab / lossis photochemical.

Vim li cas qhov dav pulse tseem ceeb?

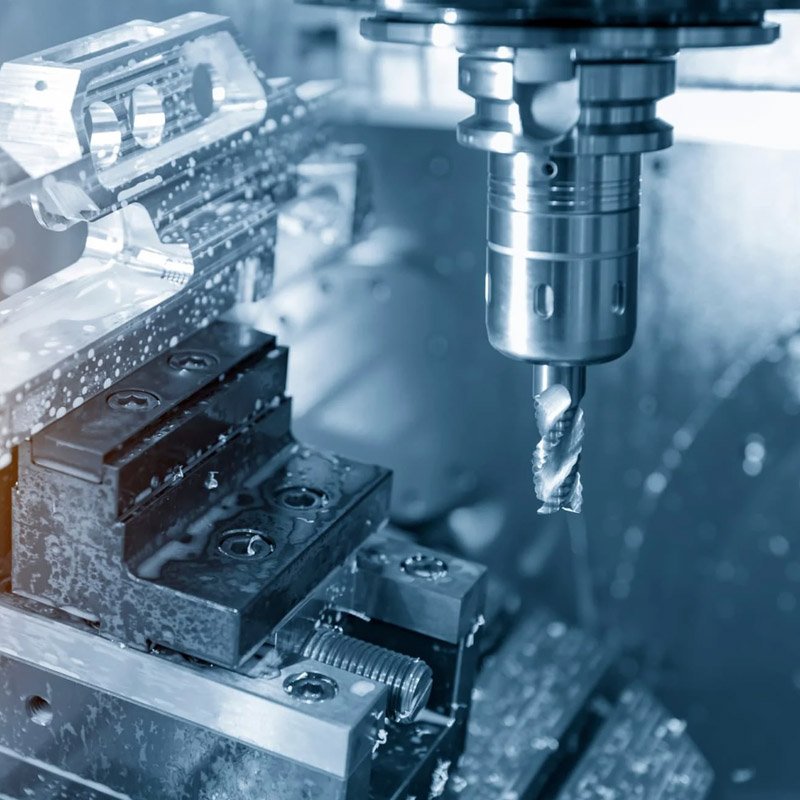

Laser txiav yog huv si thiab meej. Qhov yuav tsum tau ua kom me me, nrawm dua, sib dua thiab qis dua cov khoom siv yuav tsum tau lasers kom tau raws li qhov kev sib tw. Pulsed lasers yog siv rau precision micromachining ntawm ntau yam ntaub ntawv. Lub peev xwm los tsim kom muaj qhov sib txawv pulse widths yog tus yuam sij rau qhov raug, dhau los, zoo thiab raug nqi.

Nanosecond lasers siv tib lub zog nruab nrab nrog ntau dua cov khoom tshem tawm cov nqi thiab yog li ntawd siab dua throughput tshaj picosecond thiab femtosecond lasers.

Picosecond thiab femtosecond lasers yaj cov khoom kom tshem tawm los ntawm cov txheej txheem ntawm vaporizing thiab melting cov khoom kom tshem tawm nws. Qhov melting no tuaj yeem cuam tshuam qhov precision thiab zoo ntawm machining, vim tias cov khoom tshem tawm tuaj yeem ua raws li cov npoo thiab resolidify.

Kev nce qib hauv cov tshuab laser pulsed tau ua rau nws tuaj yeem siv micromachining ntawm cov khoom siv me me, xws li cov khoom siv kho mob, nrog rau kev puas tsuaj me me rau cov khoom nyob ib puag ncig. Nrog rau kev kawm sai sai hauv kev lag luam lasers, laser micromachining kev txawj ntse yog qhov tseem ceeb.

Cov txheej txheem ntau lawm ntawm lub tshuab yog hais txog tag nrho cov txheej txheem ntawm kev tsim cov khoom los ntawm cov khoom siv raw (lossis cov khoom tiav ib nrab). Rau kev tsim tshuab, nws suav nrog kev thauj mus los thiab khaws cov ntaub ntawv raw, kev npaj ntau lawm, kev tsim khoom tsis muaj, kev ua haujlwm thiab kev kho cua sov, cov khoom sib dhos, thiab kev debugging, painting thiab ntim, thiab lwm yam. Cov ntsiab lus ntawm cov txheej txheem ntau lawm yog qhov dav heev. Cov tuam txhab niaj hnub siv cov ntsiab lus thiab cov txheej txheem ntawm cov tshuab engineering los npaj thiab qhia kev tsim khoom, thiab suav nrog cov txheej txheem tsim khoom raws li cov txheej txheem tsim khoom nrog kev tawm tswv yim thiab tawm.

Post lub sij hawm: Oct-13-2022