Tsis yog-tus qauv kev cai CNC Machining

Tus lej tswj machining yog ib hom kev ua haujlwm uas tsis yog tus qauv, uas hloov qhov loj ntawm qhov chaw ua haujlwm lossis cov khoom ua haujlwm.Thaum siv CNC Machinery rau tshuab tshuab qhov chaw, tus kws tshaj lij yuav tsum tau ntaus tag nrho cov txheej txheem kev, cov txheej txheem kev ua haujlwm thiab cov ntaub ntawv hloov pauv tau muab tso ua ke rau hauv ib qho kev pab cuam, thiab nyob rau hauv txoj kev ntawm cov ntaub ntawv digital kaw rau hauv nruab nrab tswj los tswj cov cuab yeej siv tshuab.

Yog li nws tuaj yeem pom tias CNC tshuab cuab yeej ua cov cuab yeej siv tshuab thiab cov cuab yeej siv tshuab ua tshuab dav dav yuav luag tib yam hauv cov ntsiab lus, tab sis tag nrho cov txheej txheem ntawm CNC tshuab cuab yeej ua haujlwm yog nquag thiab zoo, txawm li cas los xij, nws kuj muaj nws tus yam ntxwv.

Numerical tswj machining cov txheej txheem ntau lawm thiab cov txheej txheem ntws

1. Cov txheej txheem ntau lawm:

Cov txheej txheem ntawm converse cov khoom raw rau hauv cov khoom yog hu ua txheej txheem ntau lawm.Cov txheej txheem tsim khoom feem ntau suav nrog kev thauj mus los thiab khaws cov khoom siv raw, kev npaj ntau lawm, kev npaj ua haujlwm dawb paug, kev siv tshuab ua haujlwm, kev kho deg, kev sib dhos, kev sim, kev debugging, kev tiv thaiv oxidation thiab ntim cov khoom, thiab lwm yam.

Cov txheej txheem tsim khoom kuj tseem tuaj yeem muab faib ua cov txheej txheem tsim khoom ntawm tag nrho lub tshuab lossis cov txheej txheem tsim khoom ntawm ib feem, hais txog cov txheej txheem tsim khoom ntawm tag nrho lub Hoobkas kev sib koom tes lossis cov txheej txheem tsim khoom ntawm ib qho kev cob qhia.

2. Cov txheej txheem thev naus laus zis:

Nyob rau hauv cov txheej txheem tshwj xeeb ntawm kev tsim khoom, hloov cov duab thiab qhov loj ntawm cov ntaub ntawv dawb huv ncaj qha, hloov mus rau cov khoom peb xav tau, thiab ua kom tiav cov khoom tiav lossis cov khoom tiav ib nrab hu ua txheej txheem thev naus laus zis.Cov txheej txheem thev naus laus zis yog qhov tseem ceeb heev thiab tseem ceeb ntawm tag nrho cov txheej txheem tsim khoom.Ib feem tseem ceeb ntawm kev ua tshuab ua lub Hoobkas tsim cov txheej txheem yog machining thev naus laus zis txheej txheem.

Dab tsi yog Cov Cheebtsam ntawm mMachining Process Flow?

1. Kev npaj ntawm Machining txheej txheem:

Cov txheej txheem machining yog xa mus rau kev ua haujlwm lossis cov txheej txheem ntawm cov neeg ua haujlwm, ua haujlwm nyob rau hauv ib qho chaw ruaj khov lossis ntawm lub tshuab ua haujlwm ruaj khov, rau ib lossis ntau qhov chaw kom tiav los ntawm cov txheej txheem machining, cov txheej txheem machining yog lub hauv paus ntawm cov txheej txheem kev ua haujlwm. , kuj yog lub hauv paus ntawm kev npaj cov phiaj xwm ntau lawm;

2. Kev teeb tsa ntawm lub workpiece:

Clamping ib feem ntawm lub tshuab nyob rau hauv ib lub sij hawm yog hu ua txheej txheem installation.Qee lub sij hawm, nyob rau hauv tib txoj kev, lub workpiece yuav tsum tau ntsia ob peb zaug kom ua tiav lub hom phiaj kawg.Nws yuav tsum tau muab sau tseg ntawm no hais tias tus naj npawb ntawm installation yuav tsum tau txo nyob rau hauv cov txheej txheem ntawm kev ua, thiaj li yuav txo tau qhov yuam kev ntawm installation thiab txuag lub sij hawm pab ntxiv.

3. Txheej txheem txheej txheem:

Nyob rau hauv qhov chaw 'ua nto, nyob rau hauv cov kev hloov pauv ntawm cov cuab yeej, ceev thiab pub, cov txheej txheem ua tiav tas li ntawm qhov ntawd yog hu ua txheej txheem kauj ruam.Cov txheej txheem txheej txheem yog lub hauv paus chav tsev ntawm cov txheej txheem machining;

4. Chaw nres tsheb ua haujlwm:

Txhawm rau ua kom tiav ib qho txheej txheem, tom qab ib zaug clamping, lub workpiece thiab lub fixture txav tau los ntawm txhua txoj hauj lwm, piv txwv li, nrog lub taub hau indexing rau milling ib hexagonal, txhua tig yog li hu ua chaw nres tsheb.

5. Pub:

Nyob rau hauv tib txoj kev cov kauj ruam, yog hais tias tus txheej txheem kuj loj, koj yuav tsum tau siv tib lub cuab tam, nyob rau tib lub ceev thiab pub, nyob rau tib txoj kev nto rau ntau zaus txiav, txhua txiav yog li hu ua ib tug pub.

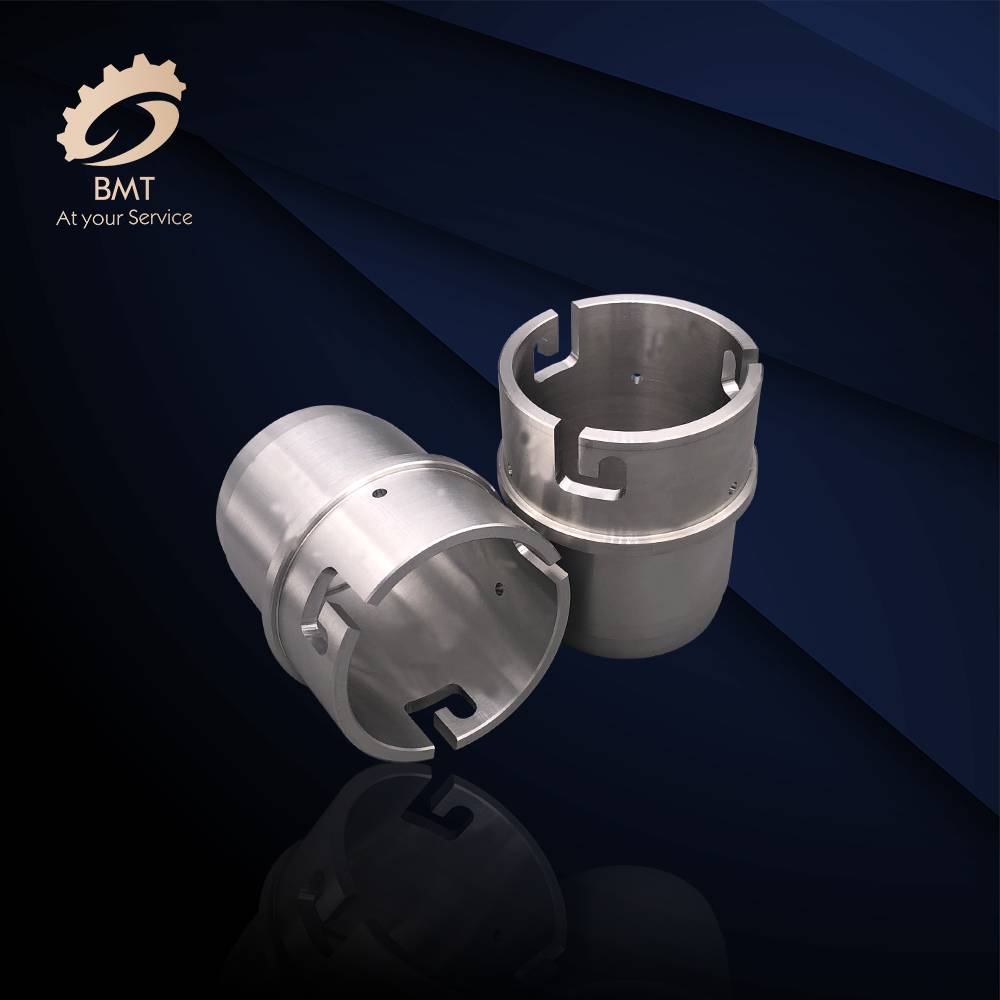

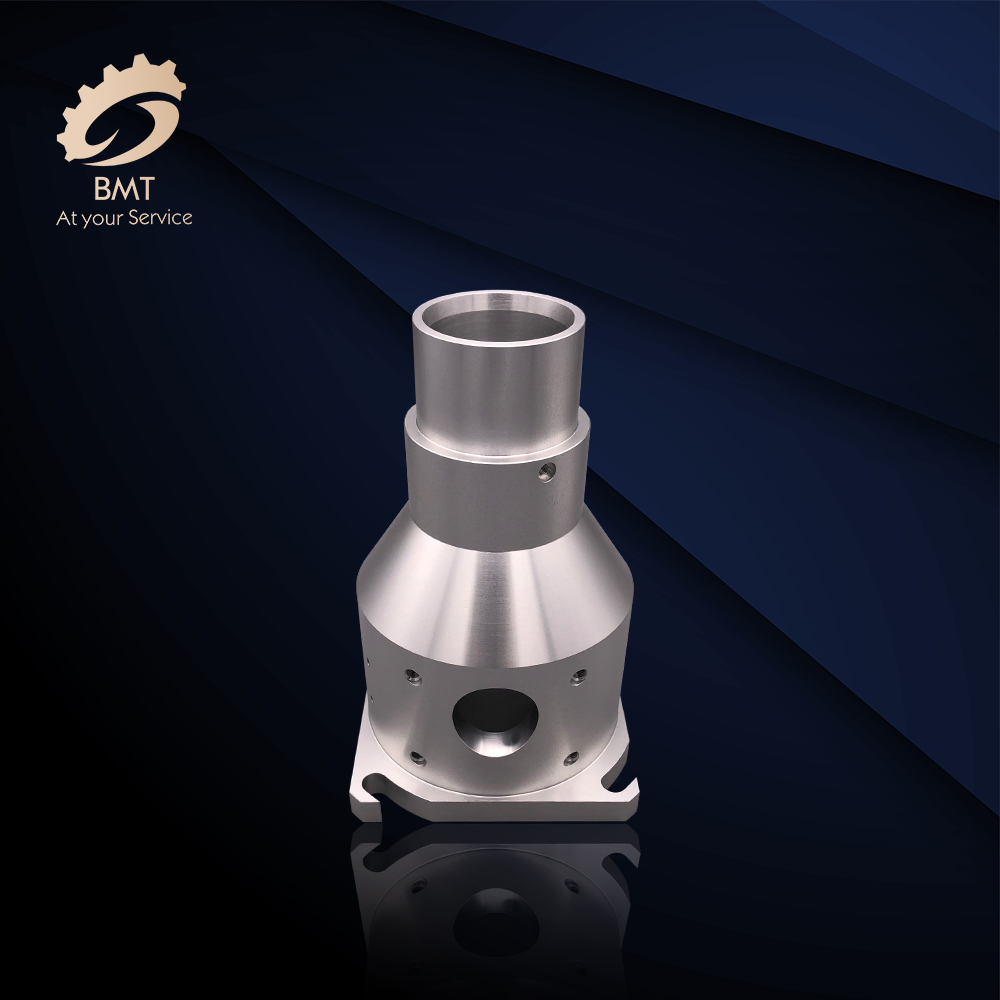

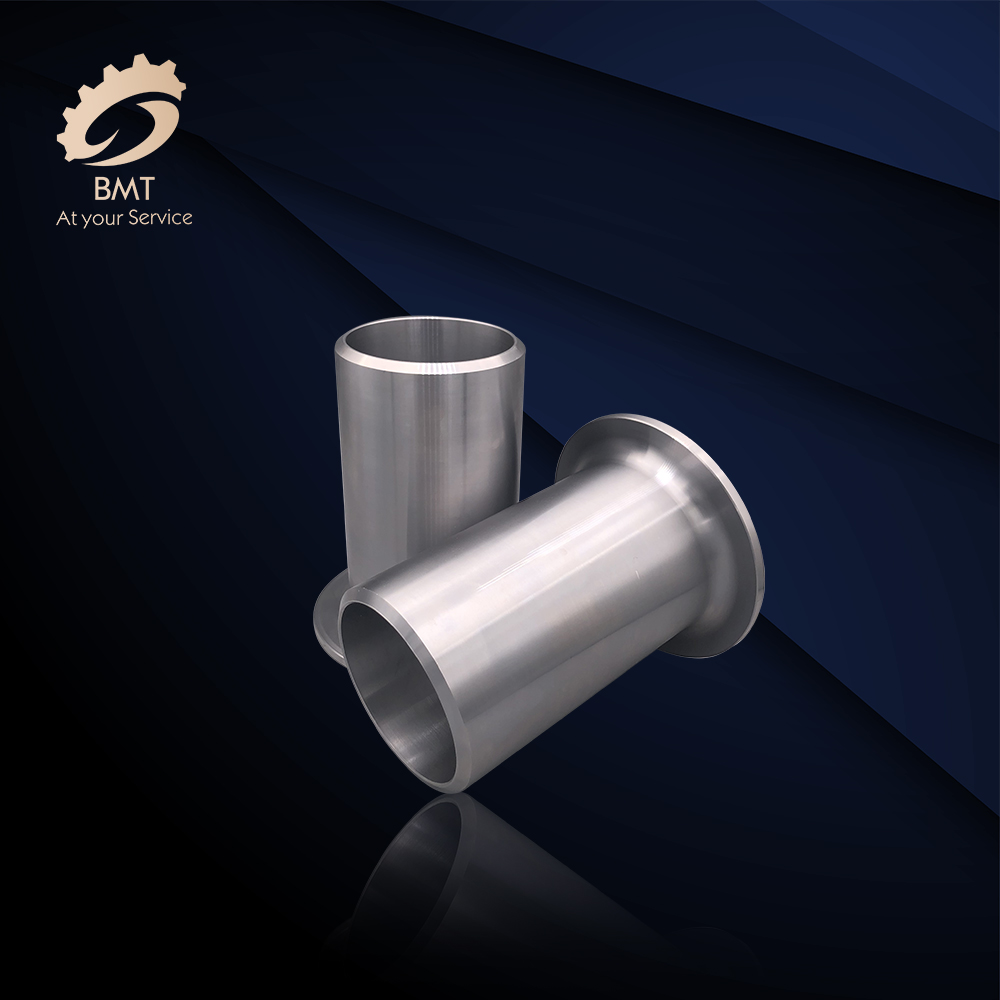

BMT yog ib tug kws CNC machinery manufacturers, Hoobkas muaj precision ua machinery, muab CNC, mechanical machining thiab lwm yam kev pab cuam.

BMT muaj kev nplua nuj nyob rau hauv kev lag luam tsheb, aerospace, mechanical, khoom noj khoom haus, lub zog, roj, kev ua liaj ua teb, thiab lwm yam., peb txais kev cai qhov chaw ua thiab txais tos koj rau kev sib tham.