BMT peev xwm

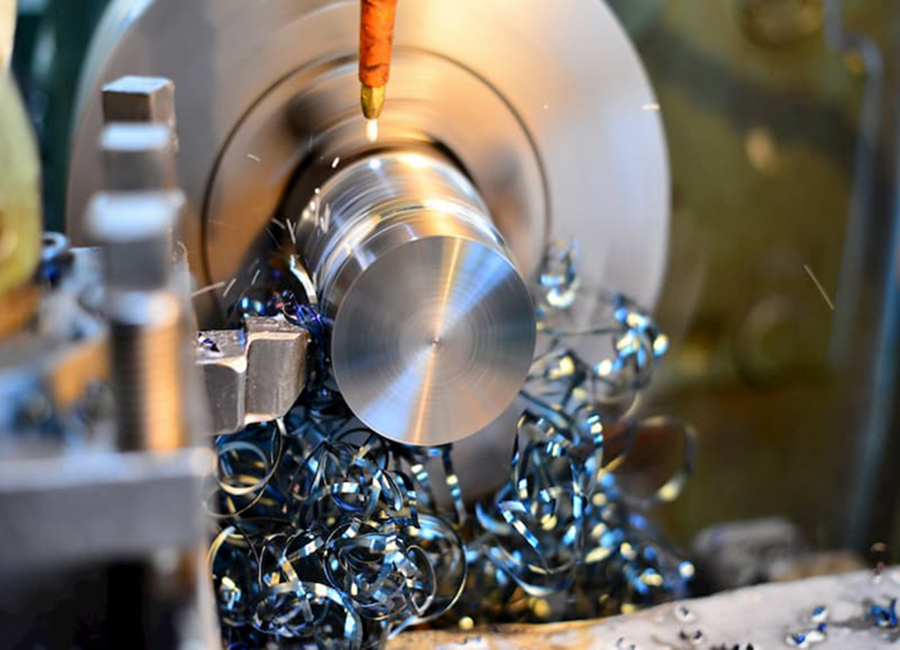

CNC (Computer Numerical Control) Machiningyog ib hom kev tsim cov khoom thiab cov khoom ua los ntawm cov khoom xws li hlau, alloys thiab engineering plastics.

Peb yog ib tug txhim khu kev qha tsum ntawm machined yas thiab hlau Cheebtsam.Ntawm no ntawm BMT, peb muaj peev xwm muab cov qauv, ib feem thiab cov khoom siv ntau lawm.Peb nkag siab tag nrho thiab meej txog qhov yuav tsum tau teb sai sai los ntawm kev nug thawj zaug mus rau kev xa khoom thiab kev pabcuam tomqab muag.

Ntawm no, Peb ua ib daim ntawv teev npe rau koj siv, tab sis qhov peb tuaj yeem ua tau tsis txwv nrog qhov no.Peb cov kev paub dhau los thiab cov kws tshaj lij engineers muab kev pabcuam rau koj ib-nres.Qhov koj yuav tsum ua yog tso siab rau peb thiab muab sijhawm rau peb ob leeg los ua haujlwm ua ke thiab koj yuav paub meej tias peb yog leej twg thiab peb tuaj yeem muab tau.Zoo siab txais tos koj txhua lub sijhawm.

Khoom siv thiab kev kho deg

| Peb yog leej twg? | Kev cai CNC Machining Parts |

| Cov ntaub ntawv muaj | Aluminium: AL5052 / AL6061 / AL6063 / AL6082 / AL7075, thiab lwm yam. |

| Brass thiab Copper: C11000 / C12000 / C36000 / C37700 / 3602 / 2604 / H59 / H62, thiab lwm yam. | |

| Carbon Steel: A105, SA182 Gr70, Q235 / Q345 / 1020 (C20) / 1025 (C25) / 1035 (C35) / 1045 (C45), thiab lwm yam. | |

| Stainless hlau: SUS304 / SUS316L / SS201 / SS301 / SS3031 / 6MnR, thiab lwm yam. | |

| Alloy Steel: Alloy 59, F44 / F51 / F52 / F53 / F55 / F61, G35, Inconel 628/825, 904L, Monel, Hastelloy, thiab lwm yam. | |

| Pwm Hlau: 1.2510 / 1.2312 / 1.2316 / 1.1730, thiab lwm yam. | |

| Yas: ABS / Polycarbonate / Nylon / Delrin / HDPE / Polypropylene / Clear Acrylic / PVC / Resin / PE / PP / PS / POM, thiab lwm yam. | |

| Lwm cov ntaub ntawv: Casting thiab Forging Pars thiab raws li tus neeg thov kev thov. | |

| Kev kho saum npoo | Oxide Blacking, Polishing, Carburizing, Anodize, Chrome Plating, Zinc Plating, Nickel Plating, Sandblasting, Laser engraving, Kev kho cua sov, hmoov txheej, thiab lwm yam. |

| Cov ntaub ntawv tawm tswv yim | CAD, DXF, STEP, PDF, thiab lwm hom ntawv tau txais. |

Machining Peev Xwm

| Kev pabcuam | Kev cai, OEM, Tsim, thiab lwm yam. |

| Hom txheej txheem | CNC tig,Milling, Drilling, Sib tsoo, Polishing, WEDM Txiav, Laser Engraving, thiab lwm yam. |

| Ua siab ntev | 0.002-0.01mm, qhov no kuj tuaj yeem kho tau. |

| Roughness | Ra0.4, Ra0.8, Ra1.6, Ra3.2, Ra6.3, thiab lwm yam, raws li Cov Neeg Siv Khoom Thov. |

| Hloov Peev Xwm | Φ1 ~ φ400 * 1500mm |

| Milling Peev Xwm | 1000 * 800 * 600 hli |

| Drilling Capacity | 2-50 hli |

| Khoom Dimension | Raws li cov neeg siv khoom thov. |

| Cov cuab yeej tshuaj xyuas | A. Mitutoyo Electronic Digital Display Caliper; B. Mitutoyo OD Digimatic Micrometer; C. Mitutoyo Precision Thaiv ntsuas; D. Caliper Depth Rule thiab Go-no Go Gauge; E. Plug Gauge thiab R Gauge; F. ID Digimatic Micrometer; G. Xov Ring Gauge thiab Plug Gauge; H. Peb Lub Tshuab Ntsuas Ntsuas; I. Lub kaum ntse ntse thiab ntsuas ntsuas; J. ID Gages thiab Microscope; K. Qhov taw qhia qhov siab thiab Dial qhov taw qhia; L. Sab hauv Caliper thiab Dialgage; M. Projector kuaj tshuab; N. Qib ntawm Marble Platform; |

Post lub sij hawm: Jan-10-2021