Peb txaus siab rau cov neeg siv khoom txaus siab thiab kev lees paub dav dav vim peb qhov kev pheej hmoo siab tshaj plaws ntawm txhua qhov kev daws teeb meem thiab kho kom txo qis Tuam Tshoj CNC Tig Brass Parts Lathe Turning Mechanical Parts CNC Machining Works Hlau Fabrication Service, Peb zoo siab tos txais cov neeg tuaj saib, me me. cov koom haum ua lag luam thiab cov phooj ywg los ntawm txhua daim ntawv hauv ntiaj teb kom tau tuav peb thiab nrhiav kev koom tes rau kev sib nrig sib zoo.

Peb zoo siab rau cov neeg yuav khoom txaus siab thiab kev lees txais dav vim peb pheej nrhiav kev sab saum toj ntawm txhua qhov kev daws teeb meem thiab kho rauTuam Tshoj CNC tig Part, Cov khoom yas, Peb lees paub rau pej xeem, kev koom tes, yeej-yeej qhov xwm txheej raws li peb lub hauv paus ntsiab lus, ua raws li lub tswv yim ntawm kev ua neej zoo, ua kom muaj kev ncaj ncees, ua siab dawb cia siab tias yuav tsim kom muaj kev sib raug zoo nrog ntau thiab ntau tus neeg siv khoom thiab cov phooj ywg, kom ua tiav qhov xwm txheej yeej-yeej thiab kev vam meej.

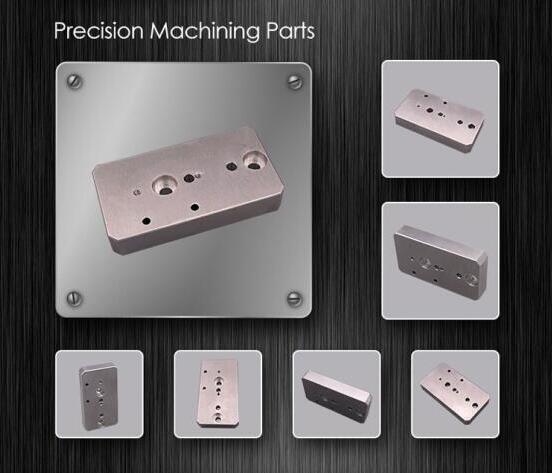

Niaj hnub Machining cuab yeej

Cov txheej txheem hlau fabrication feem ntau yog ib txoj hauv kev zoo los tsim cov khoom muab, txawm li cas los xij, ib tus xav tau cov cuab yeej niaj hnub ntxiv kom ua tiav qib siab ntawm qhov tshwj xeeb thiab sib xws. Ua li no, cov cuab yeej machining tuaj yeem siv los xaiv tshem tawm lossis ua tiav ib daim hlau lossis cov khoom siv hlau. Cov cuab yeej siv tshuab niaj hnub yog ib txwm siv los ntawm hluav taws xob; Ntxiv automation ntawm cov txheej txheem machining tuaj yeem ua tiav los ntawm kev siv lub tshuab CNC tshuab, coj los ntawm lub khoos phis tawj programming. Cov txiaj ntsig tseem ceeb ntawm cov cuab yeej machining niaj hnub yog qhov tshwj xeeb tsis sib xws uas lawv xa thaum tsim khoom ntau yam nrog cov tsis sib xws thiab cov kev xav tau. Ntau cov cuab yeej machining niaj hnub no tsuas yog kev txhim kho ntawm phau ntawv machining cov cuab yeej uas tau nyob ib puag ncig rau ntau pua xyoo. Lwm qhov kev tsim qauv tshiab tuaj yeem ua tau vim tias tsis ntev los no kev nce qib hauv thev naus laus zis.

Cov cuab yeej niaj hnub siv hauv kev tsim khoom

Niaj hnub no, feem ntau hom machining thiab hlau fabrication cov cuab yeej tuaj yeem muab tso rau hauv cov hauv qab no:

Tshuab dhos

Drilling tshuab

Milling tshuab

Hobbing tshuab

Honing tshuab

Iav shapers

Planer tshuab

Sib tsoo tshuab

Broaching tshuab

Lub tshuab dhos muaj ib qho kev sib hloov ua haujlwm raws li qhov khoom siv tau (qhov no, hlau) tau muab tso rau - qhov tshwm sim yog qhov sib luag thiab qhov tshwj xeeb ntawm cov khoom. Raws li cov khoom tig, ntau yam cuab yeej siv los txiav, knurl, laum lossis lwm yam hloov cov hlau. Kev sib txhuam ntawm kev sib hloov ua rau muab cov txheej txheem yooj yim rau kev xa cov txiaj ntsig zoo ib puag ncig ntawm tag nrho ib puag ncig ntawm ib qho khoom, ua lathes xaiv zoo rau cov khoom lag luam uas sib luag nyob ib puag ncig axis ntawm kev sib hloov. Lathes sib txawv me me, nrog rau qhov tsawg tshaj plaws yog handheld versions siv rau cov hniav nyiaj hniav kub thiab watchmaking.

Drilling tshuab, tseem hu ua laum presses, muaj xws li ib tug ruaj laum uas yog mounted los yog bolted rau ib tug sawv los yog workbench. Drill presses yog siv ntau yam tib yam li kev tuav tes thiab lub zog xyaum, txawm li cas los xij, qhov chaw nyob ruaj khov ntawm cov xovxwm yuav tsum muaj kev tawm dag zog tsawg kom ua tiav qhov drilling thiab ruaj khov dua. Cov yam ntxwv xws li lub kaum sab xis ntawm lub laum ntxaiv tuaj yeem kho thiab tswj kom tso cai rau rov ua dua thiab zoo ib yam. Niaj hnub nimno hom drilling tshuab muaj xws li pedestal xyaum, lub rooj ntev zaum xyaum, thiab pillar xyaum.

Zoo ib yam li cov tshuab drilling,milling tshuabsiv lub stabilized rotating cutter rau tshuab ib piece ntawm hlau, tab sis cia ntau versatility los ntawm kev ntxiv rau kev txiav sideways. Qee lub tshuab milling niaj hnub no muaj lub tshuab txiav txawb, thaum lwm tus muaj lub rooj txawb uas txav ntawm lub tshuab txiav kom ua tiav qhov xav tau ua tiav. Ntau hom milling tshuab suav nrog tes milling tshuab, milling tshuab, universal milling machines thiab universal milling machines. Txhua hom milling tshuab muaj nyob rau hauv ntsug thiab kab rov tav configurations.

Ahobbing tshuabzoo ib yam li lub tshuab milling nyob rau hauv uas ib tug rotating cutter ua qhov txiav txiav, txawm li cas los xij, lawv tso cai rau ib txhij txav ntawm ob lub cutter thiab cov khoom raug machined. Lub peev xwm tshwj xeeb no ua rau hobbing zoo tagnrho rau 3D machining daim ntawv thov uas xav tau cov hniav sib xws. Iav txiav yog ib qho kev siv ntau tshaj plaws rau cov tshuab hobbing niaj hnub.

Honing tshuab, tseem hu ua hones, muaj feem ntau ntawm ib los yog ntau lub tswv yim rotating uas, nyob rau hauv metalworking, loj qhov rau ib tug meej txoj kab uas hla thiab txhim kho nto tiav. Hom honing tshuab muaj xws li handheld, phau ntawv thiab tsis siv neeg. Cov khoom tsim nrog kev pab ntawm honing muaj xws li lub tog raj kheej cav.

Whereas lub tshuab hobbing txiav cov hniav sab nraud ntawm lub iav, niaj hnubiav shaperstsim cov hniav hauv cov hniav. Qhov no yog ua tiav los ntawm kev siv lub tshuab txiav reciprocating uas muaj tib lub suab zoo li lub iav raug txiav. Niaj hnub nimno iav shapers tso cai rau kom nce precision los ntawm kev siv rau pem hauv ntej stroke kev koom tes thiab rov qab stroke disengagement.

Cov phiaj xwmyog cov tshuab loj loj shaping uas txav cov khoom siv hlau tiag tiag uas tsis yog txav lub tshuab txiav. Cov txiaj ntsig zoo ib yam li lub tshuab milling, ua cov phiaj xwm zoo rau shaping tiaj tus lossis ntev qhov chaw. Niaj hnub nimno milling tshuab yog me ntsis superior rau planers nyob rau hauv feem ntau daim ntaub ntawv; Txawm li cas los xij, cov phiaj xwm tseem muaj txiaj ntsig zoo thaum cov khoom siv hlau loj heev xav tau squaring tawm.

grindersyog cov cuab yeej machining niaj hnub uas siv lub log abrasive los tsim kev ua tiav zoo los yog faint txiav. Nyob ntawm qhov tshwj xeeb grinder, lub log abrasive lossis cov khoom raug txav ntawm sab mus rau sab kom ua tiav qhov xav tau. Hom kev sib tsoo muaj xws li siv lub tshuab, lub rooj zaum grinders, cylindrical grinders, nto grinders, thiab jig grinders.

Atshuab broaching, los yog broach, siv cov chisel siab cov ntsiab lus los siv linear shearing thiab scraping motions rau cov khoom muab. Broaches feem ntau yog siv los tsim cov duab uas tsis yog lub voj voog tawm ntawm lub qhov uas tau raug ntaus los ntawm cov hlau. Lawv kuj txiav splines thiab keyways ntawm lub zog thiab pulleys. Rotary broaches yog ib qho tshwj xeeb ntawm cov tshuab broaching, siv ua ke nrog lub tshuab dhos los tsim ib qho kev sib dhos kab rov tav thiab ntsug txiav.

Peb txaus siab rau cov neeg siv khoom txaus siab thiab kev lees paub dav dav vim peb qhov kev pheej hmoo siab tshaj plaws ntawm txhua qhov kev daws teeb meem thiab kho kom txo qis Tuam Tshoj CNC Tig Brass Parts Lathe Turning Mechanical Parts CNC Machining Works Hlau Fabrication Service, Peb zoo siab tos txais cov neeg tuaj saib, me me. cov koom haum ua lag luam thiab cov phooj ywg los ntawm txhua daim ntawv hauv ntiaj teb kom tau tuav peb thiab nrhiav kev koom tes rau kev sib nrig sib zoo.

Peb txaus siab rau cov neeg siv khoom txaus siab thiab kev lees paub dav dav vim peb qhov kev pheej hmoo siab tshaj plaws ntawm txhua qhov kev daws teeb meem thiab kho kom txo qis Tuam Tshoj CNC Tig Brass Parts Lathe Turning Mechanical Parts CNC Machining Works Hlau Fabrication Service, Peb zoo siab tos txais cov neeg tuaj saib, me me. cov koom haum ua lag luam thiab cov phooj ywg los ntawm txhua daim ntawv hauv ntiaj teb kom tau tuav peb thiab nrhiav kev koom tes rau kev sib nrig sib zoo.

Kev txo nqi lojTuam Tshoj CNC tig Part, Cov khoom yas, Peb lees paub rau pej xeem, kev koom tes, yeej-yeej qhov xwm txheej raws li peb lub hauv paus ntsiab lus, ua raws li lub tswv yim ntawm kev ua neej zoo, ua kom muaj kev ncaj ncees, ua siab dawb cia siab tias yuav tsim kom muaj kev sib raug zoo nrog ntau thiab ntau tus neeg siv khoom thiab cov phooj ywg, kom ua tiav qhov xwm txheej yeej-yeej thiab kev vam meej.