Txhawm rau dhau los ua theem ntawm kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab, muaj kev sib koom siab ntau thiab ntau tus kws tshaj lij ua haujlwm! Kom ncav cuag ib qho txiaj ntsig ntawm peb cov neeg yuav khoom, cov chaw muag khoom, lub zej zog thiab peb tus kheej rau Kev txo nqi loj Tuam Tshoj High Precision Hlau Stamping Parts Machining CNCTurned Parts Chaw tsim tshuaj paus, Thawj Tswj Hwm ntawm peb lub tuam txhab, nrog rau tag nrho cov neeg ua haujlwm, txais tos txhua tus neeg yuav khoom tuaj xyuas peb lub tuam txhab thiab tshuaj xyuas. Cia peb koom tes hauv tes ua kom muaj lub neej yav tom ntej zoo.

Txhawm rau dhau los ua theem ntawm kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab, muaj kev sib koom siab ntau thiab ntau tus kws tshaj lij ua haujlwm! Txhawm rau kom ncav cuag cov txiaj ntsig ntawm peb cov neeg yuav khoom, cov neeg muag khoom, lub zej zog thiab peb tus kheej rauTuam Tshoj Machining CNC, Turned Parts Chaw tsim tshuaj paus, Peb tau ntseeg siab tias peb muaj peev xwm muab sijhawm rau koj thiab tej zaum yuav yog ib tus khub lag luam tseem ceeb ntawm koj. Peb tos ntsoov yuav ua haujlwm nrog koj sai sai. Kawm paub ntau ntxiv txog hom khoom muag uas peb ua haujlwm nrog lossis tiv tauj peb tam sim no ncaj qha nrog koj cov lus nug. Koj tuaj yeem tiv tauj peb txhua lub sijhawm!

Kev cai ua CNC Machining Parts

Mechanical parts processing technology yog hais txog cov txheej txheem ntawm kev hloov qhov ntev lossis cov khoom ntawm lub workpiece los ntawm cov cuab yeej siv tshuab. Raws li qhov sib txawv ntawm txoj kev ua, nws tuaj yeem muab faib ua kev txiav thiab kev ua haujlwm siab.

Mechanical qhov chaw ua cov txheej txheem feem ntau suav nrog: tig, milling, npaj, ntxig, sib tsoo, drilling, tho txawv, xuas nrig ntaus, sawing thiab lwm yam. Nws tseem tuaj yeem suav nrog hlau txiav, casting, forging, electro-corrosion, hmoov ua, electroplating, thiab kev kho cua sov thiab lwm yam.

1. Kev tig:

Muaj ntsug tshuab dhos tshuab thiab kab rov tav tshuab dhos tshuab; cov cuab yeej tshiab muaj CNC tshuab dhos tshuab, feem ntau yog ua lub cev teb;

2. Milling:

Muaj ntsug milling thiab kab rov tav milling; Cov cuab yeej tshiab muaj CNC milling, tseem hu ua CNC machining chaw, feem ntau cov txheej txheem zawj thiab cov duab npaj cheeb tsam. Tau kawg, nws tseem tuaj yeem ua cov camber nrog ob axes lossis peb axes CNC Machining Center.

3. Kev npaj:

Feem ntau cov txheej txheem zoo li kev npaj thaj chaw nto. Raws li ib txwm muaj, qhov roughness ntawm qhov chaw tsis siab tshaj lub tshuab milling;

4. Inserting:

Nws tuaj yeem nkag siab tias yog ib qho ntsug planer, haum rau kev ua tsis tiav cov voj voog arc.

5. Sib tsoo:

Muaj dav hlau sib tsoo, ncig sib tsoo, puab qhov sib tsoo, thiab cov cuab yeej sib tsoo, thiab lwm yam. High precision nto ua, lub workpiece nto roughness yog tshwj xeeb yog siab;

6. Drilling:

Nquag, nws yog qhov ua haujlwm.

7. Ntsuag:

Nws yog qhov tho txawv tsuas yog los ntawm cov cuab yeej tho txawv lossis cov hniav, nrog rau kev ua tiav ntawm txoj kab uas hla loj, siab precision qhov, thiab cov duab loj dua.

8. Punching:

Nws yog tsuas yog xuas nrig ntaus molding los ntawm lub tshuab xuas nrig ntaus, uas tuaj yeem xuas nrig puag ncig lossis qhov tshwj xeeb zoo li lub qhov.

9. Txiav thiab Sawing:

Nws yog tsuas yog txiav cov khoom los ntawm lub tshuab sawing, feem ntau siv rau hauv cov txheej txheem blanking.

Txhua lub tshuab yog tsim los ntawm ntau qhov tseeb, tsis muaj qhov machining, lub tshuab ua tsis tiav. Tias yog vim li cas vim li cas cov machining qhov chaw ua lub luag haujlwm tseem ceeb tshaj plaws hauv kev lag luam mechanical.

Nrog rau txoj kev loj hlob ntawm automation, mechanical processing technology kuj tau pib automate cov kev taw qhia ntawm evolution tsis tu ncua, nws yuav tsum ua lub luag haujlwm tseem ceeb hauv kev txhim kho lub neej yav tom ntej, koj paub, lub zog ntawm cov txheej txheem siv tshuab yog kev loj hlob ntawm lub teb chaws kev lag luam. Hauv BMT, peb siv thev naus laus zis zoo heev, txhawm rau muab qhov zoo tshaj plaws machining qhov chaw rau peb cov neeg siv khoom. Yog tias xav tau, thov hu rau peb tam sim.

Product Description

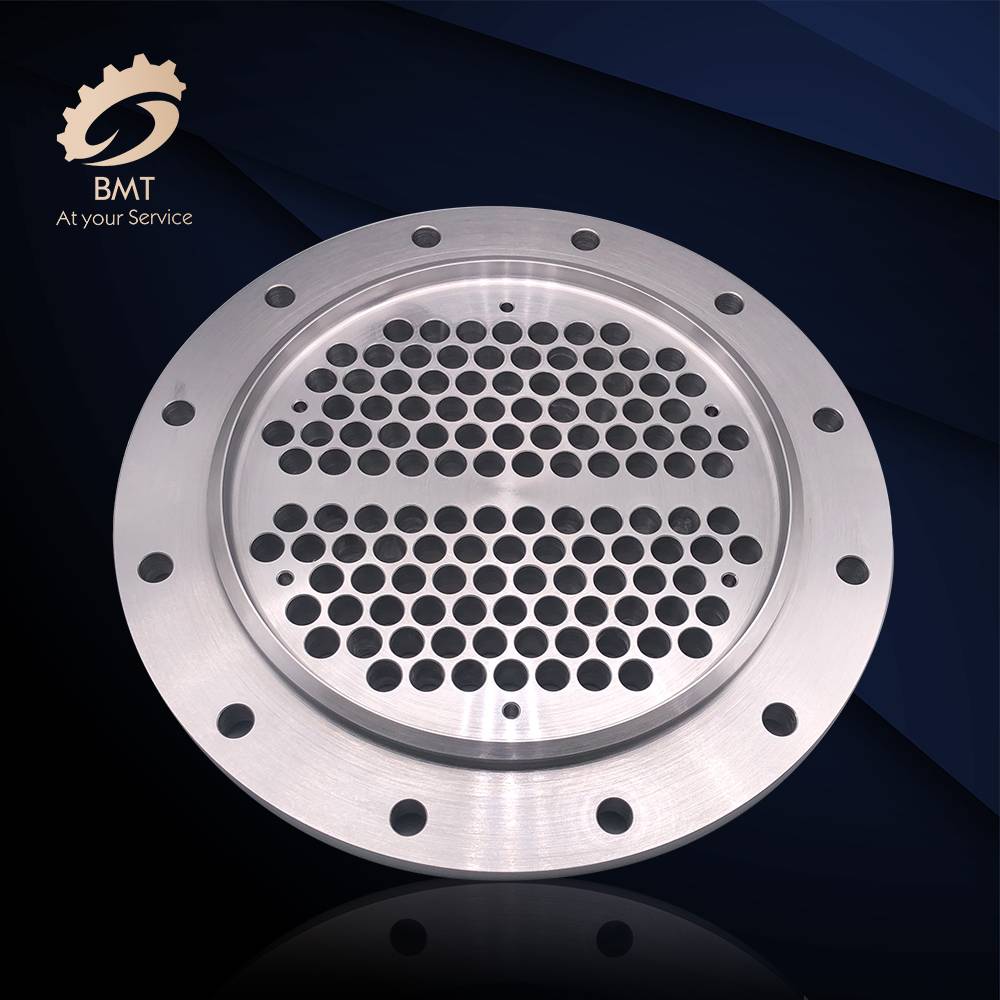

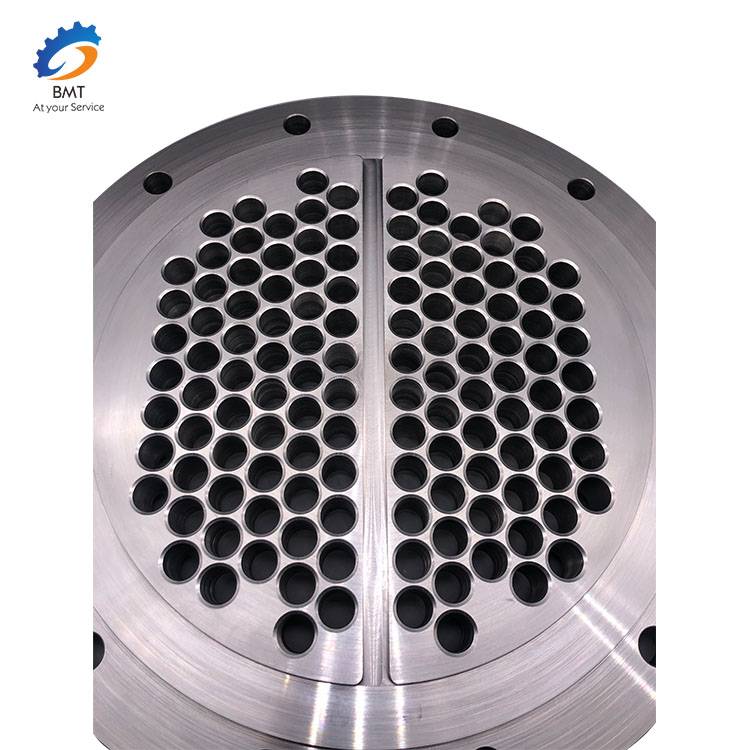

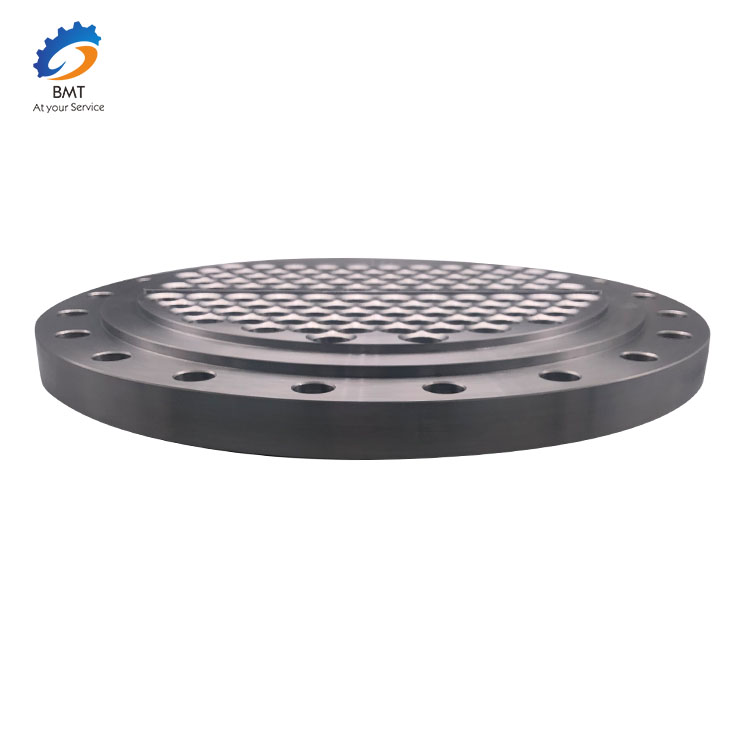

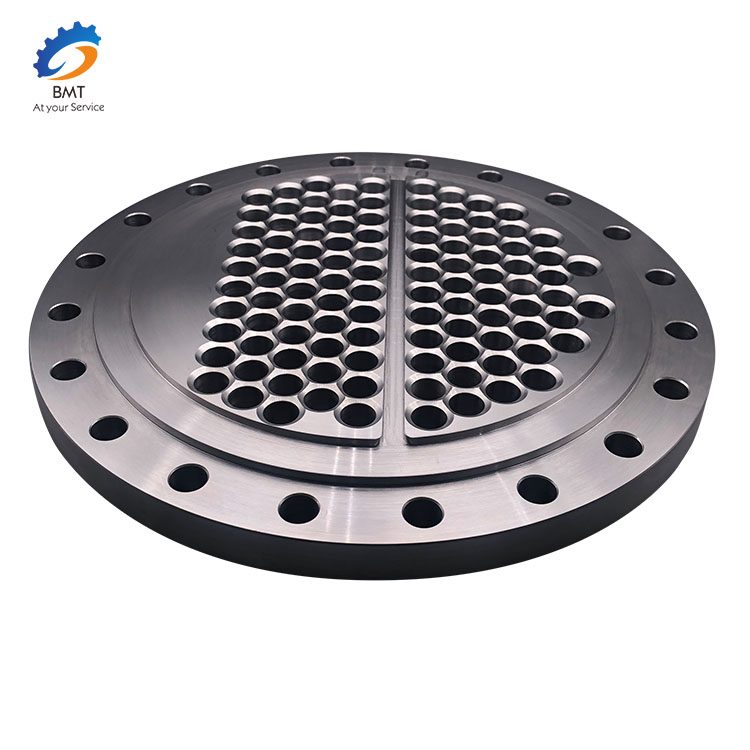

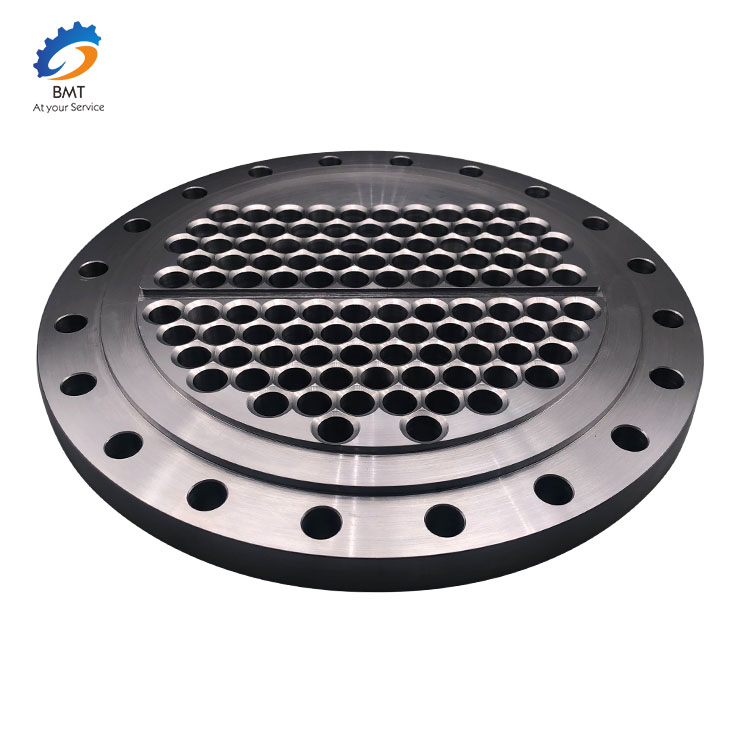

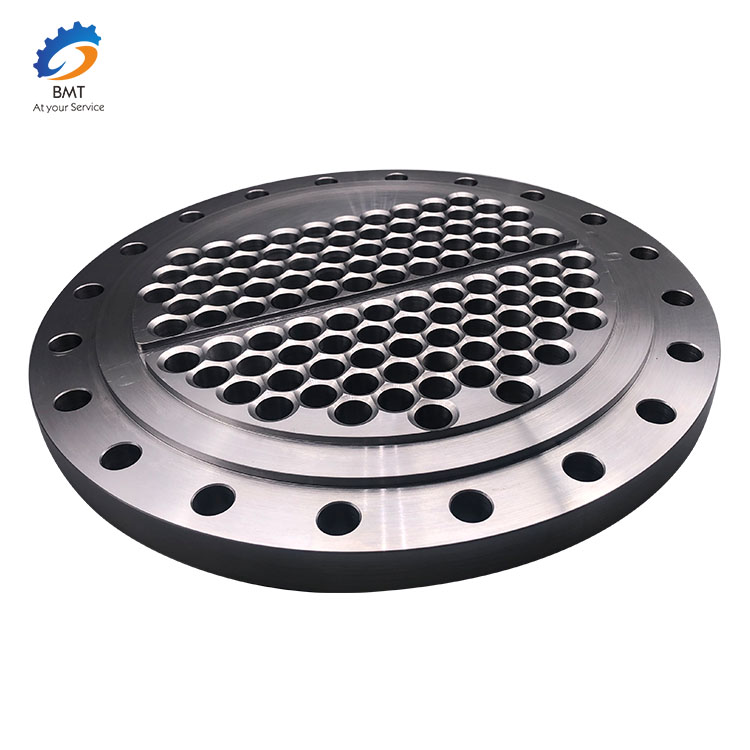

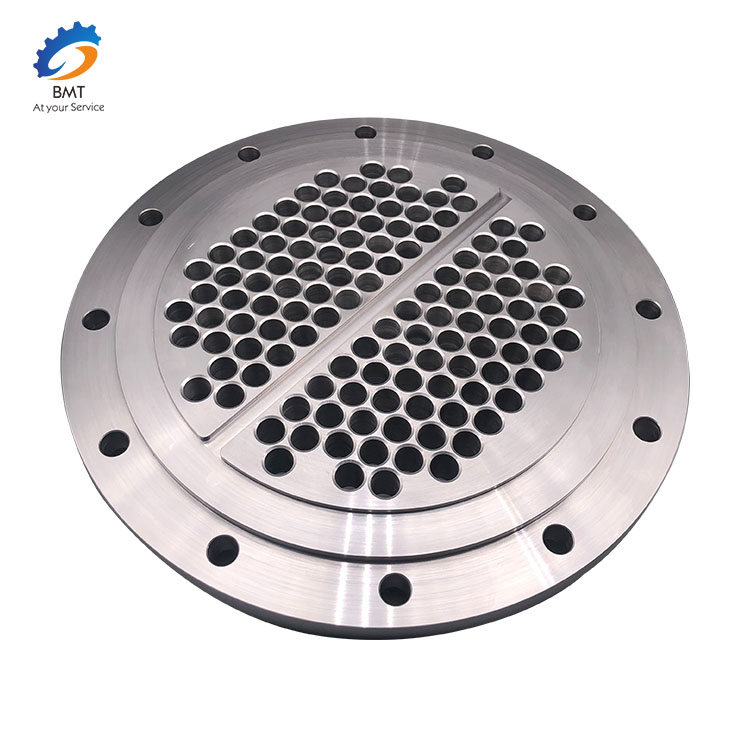

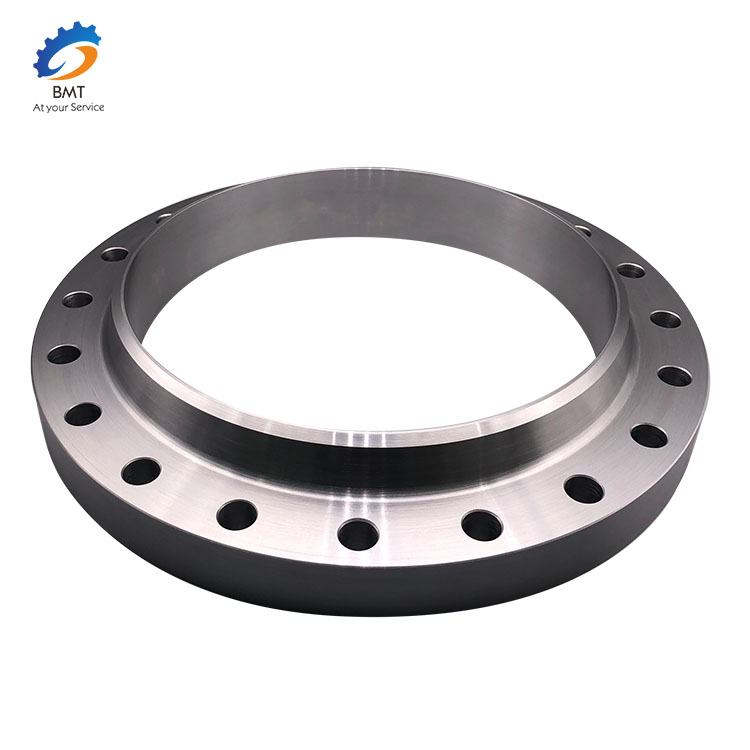

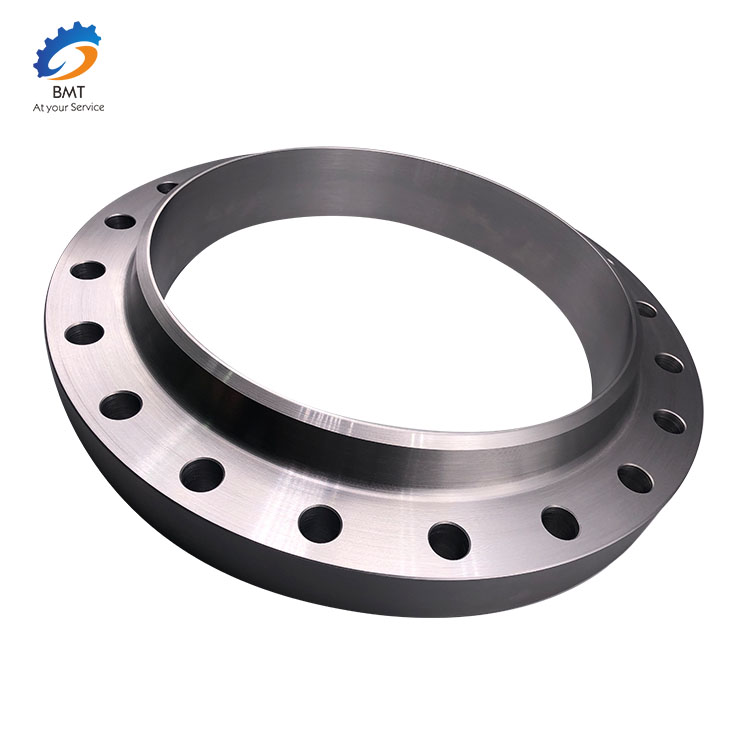

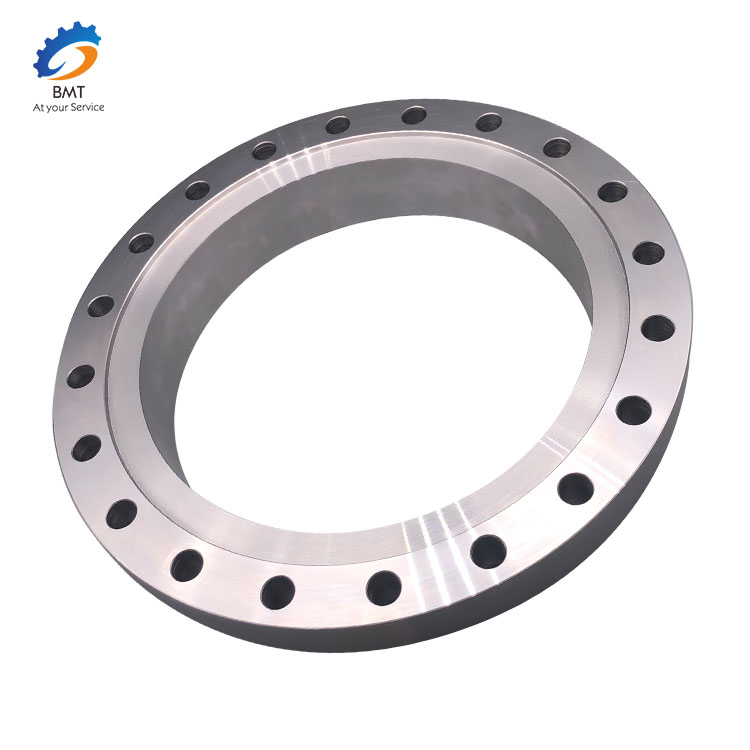

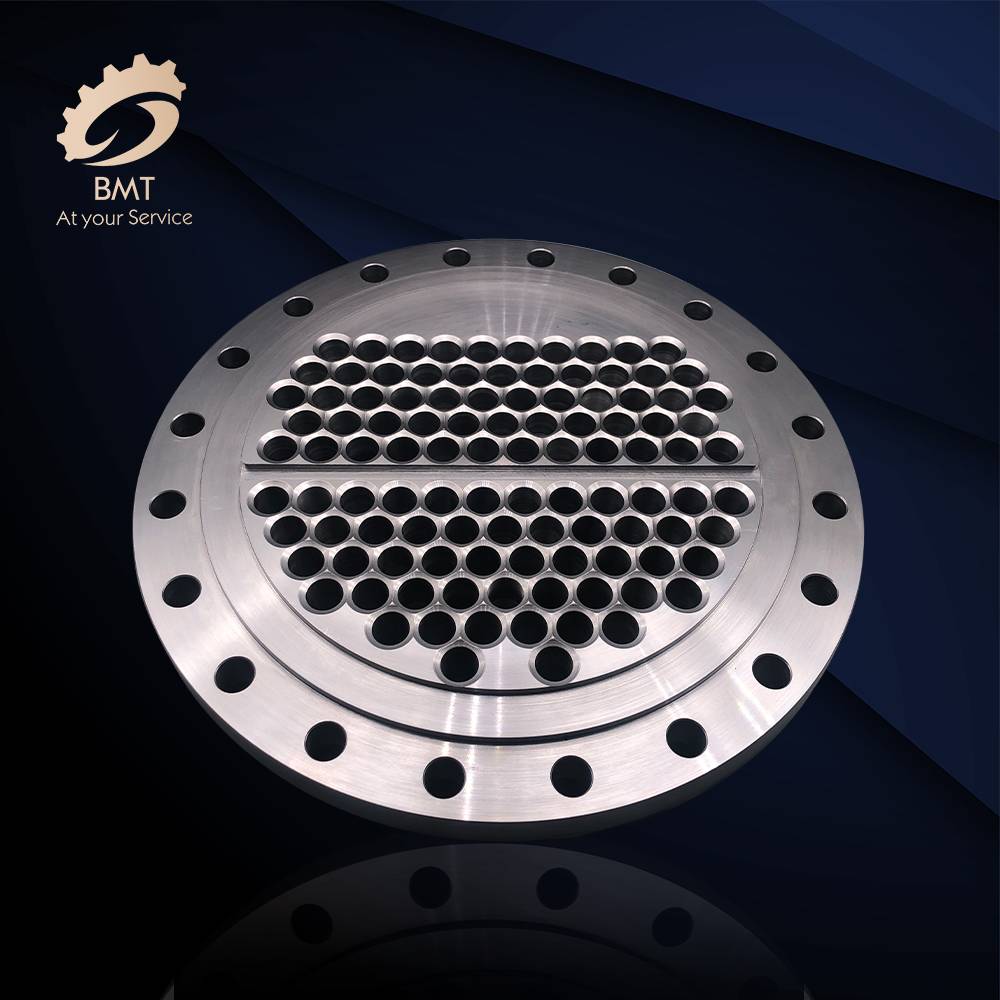

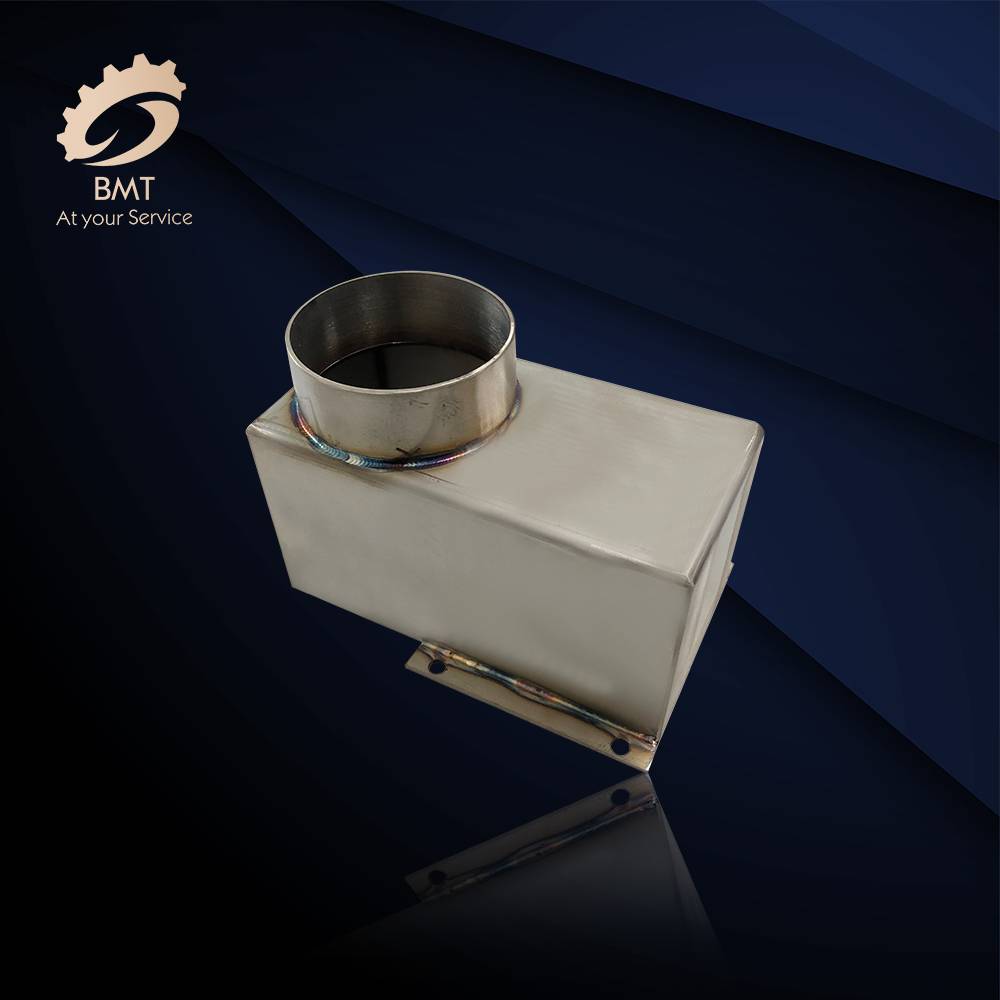

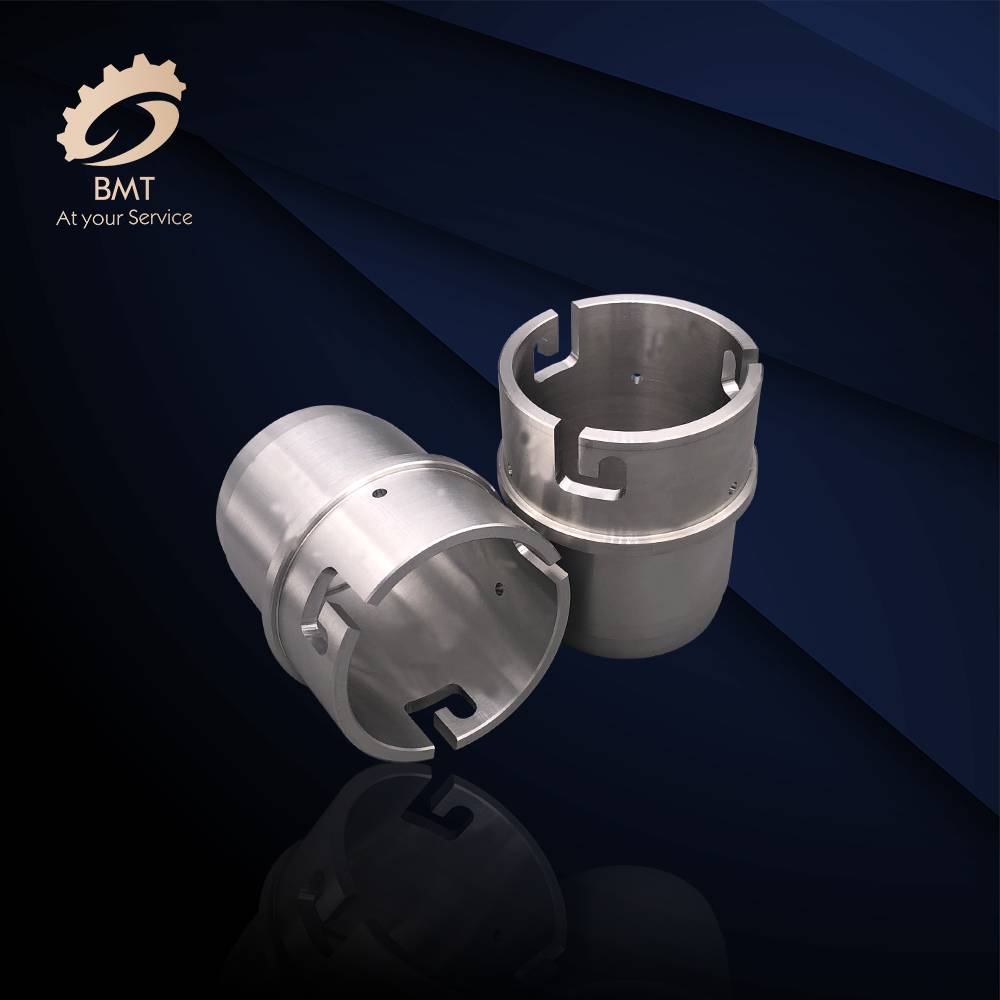

Phaj tube 1

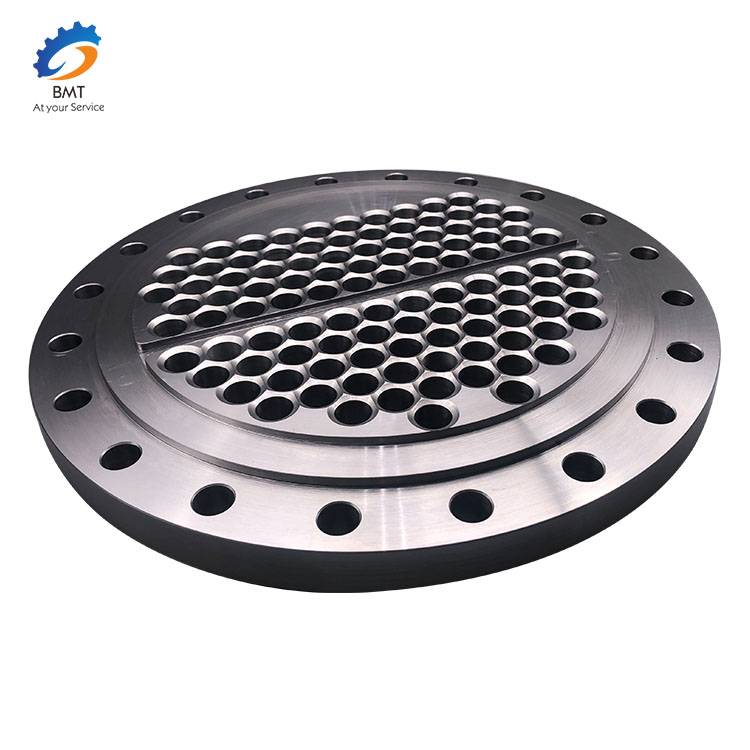

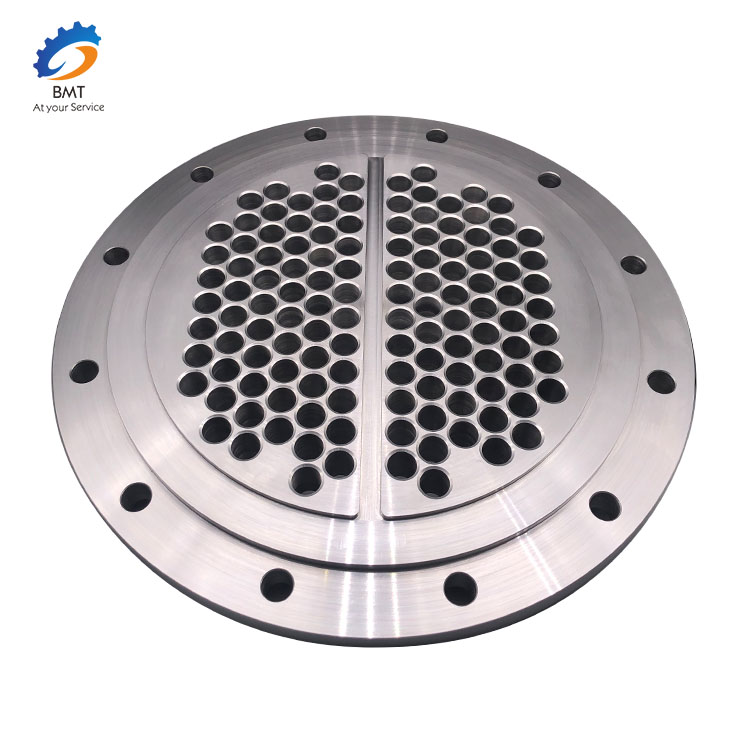

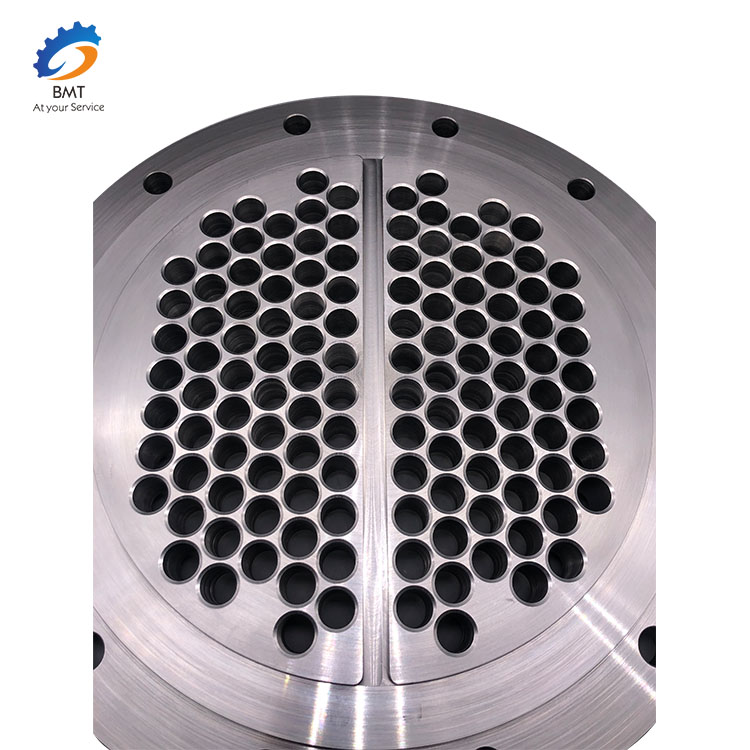

Phaj tube 2

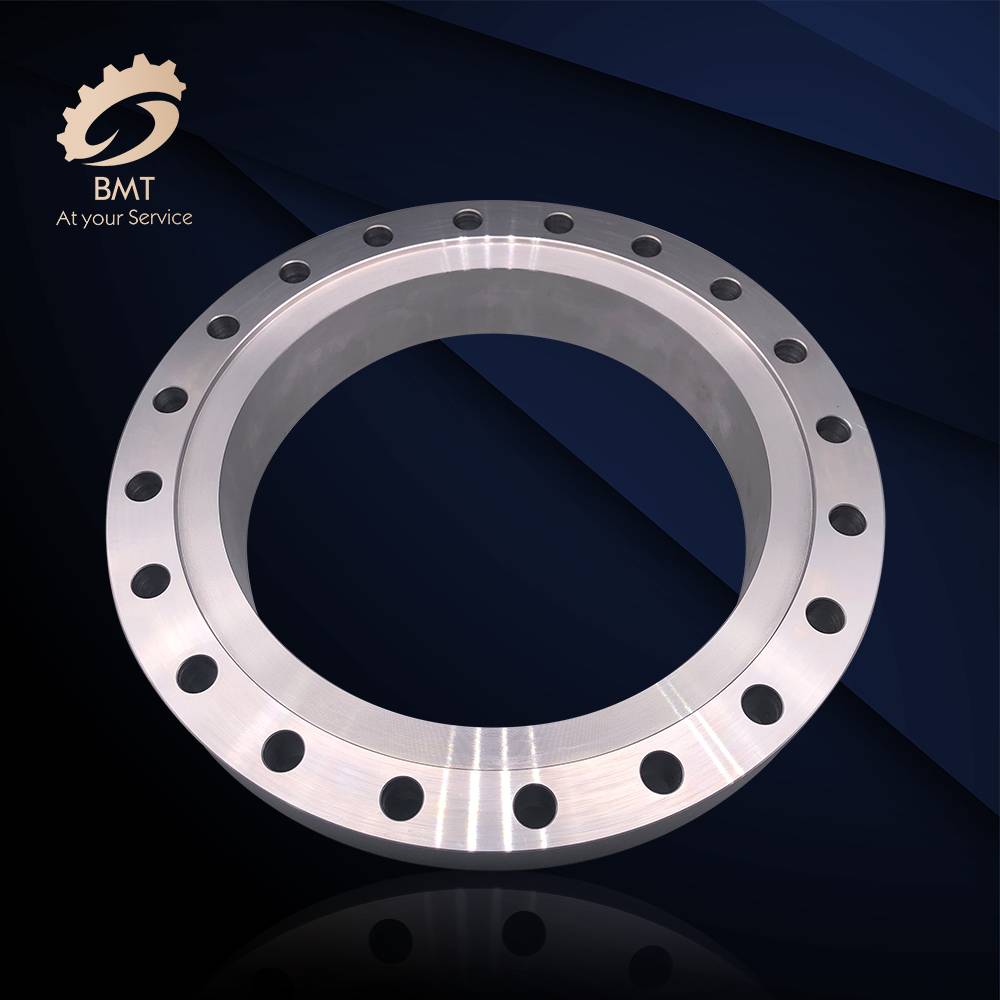

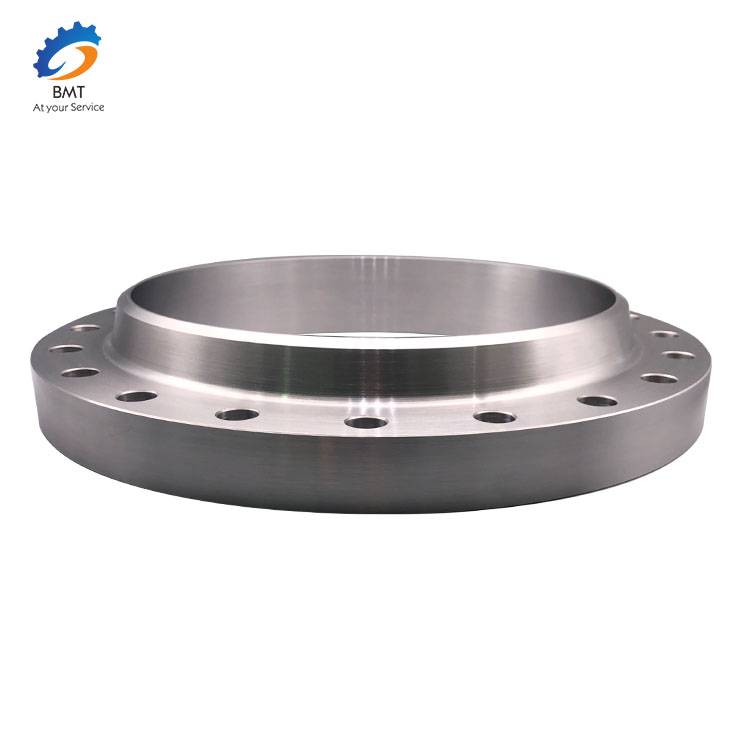

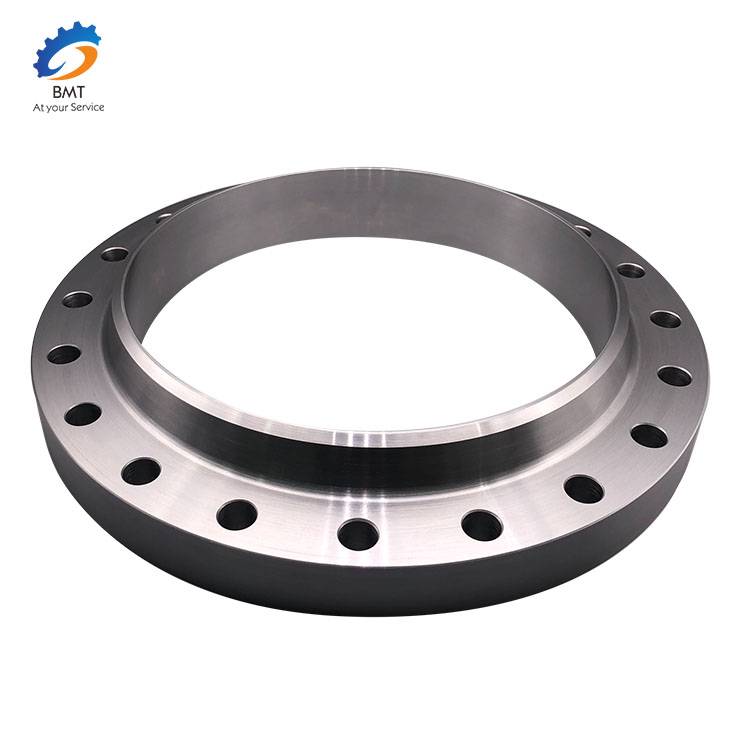

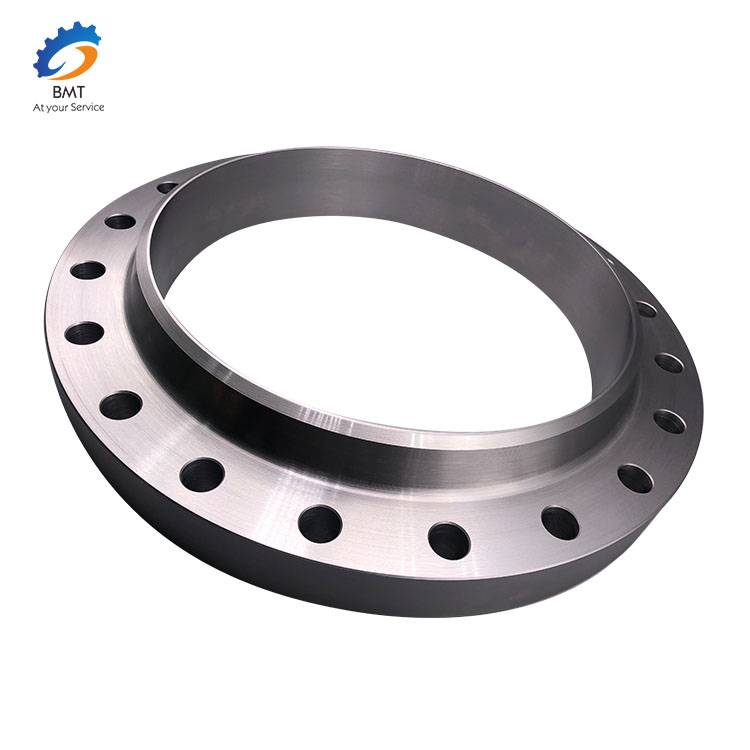

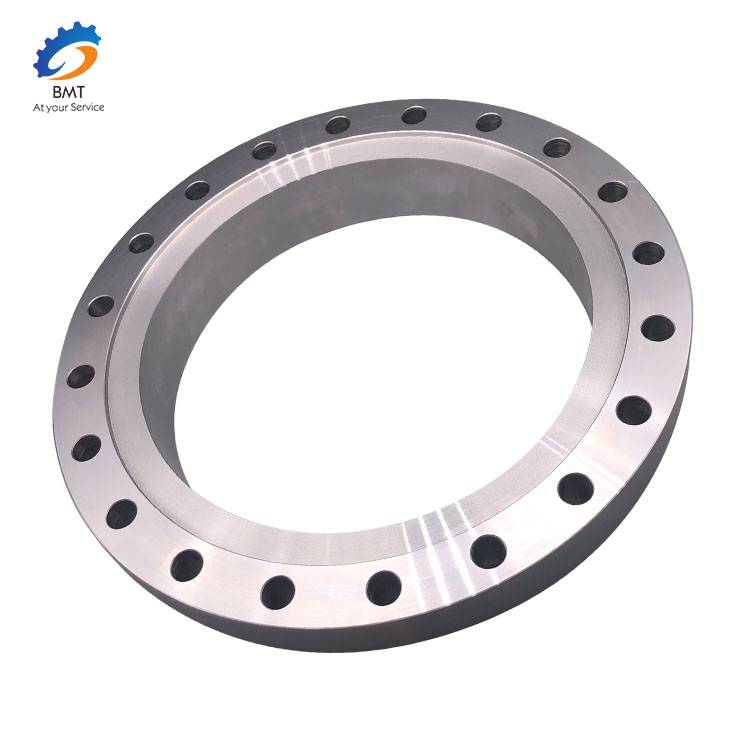

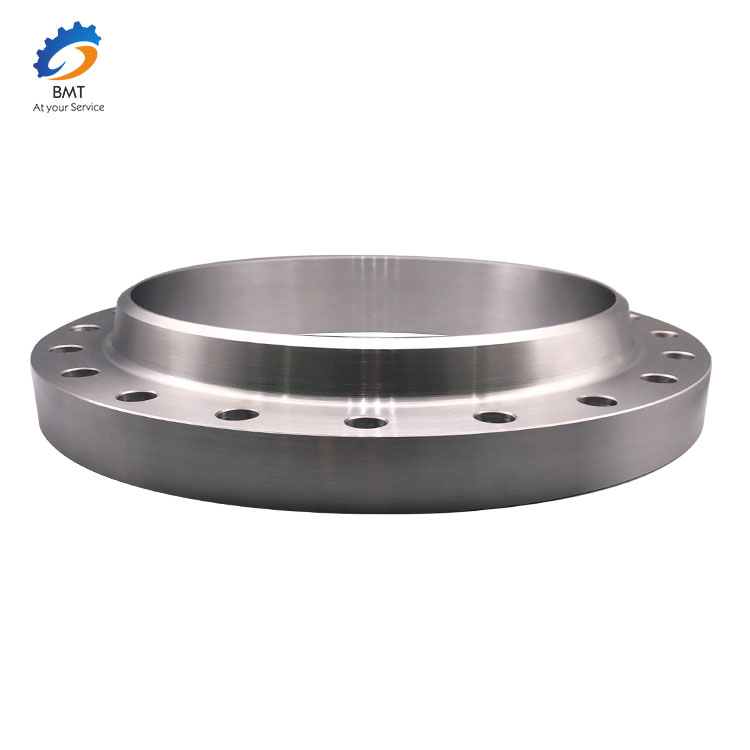

Lub flange

Phaj tube 1

Phaj tube 2

Lub flange

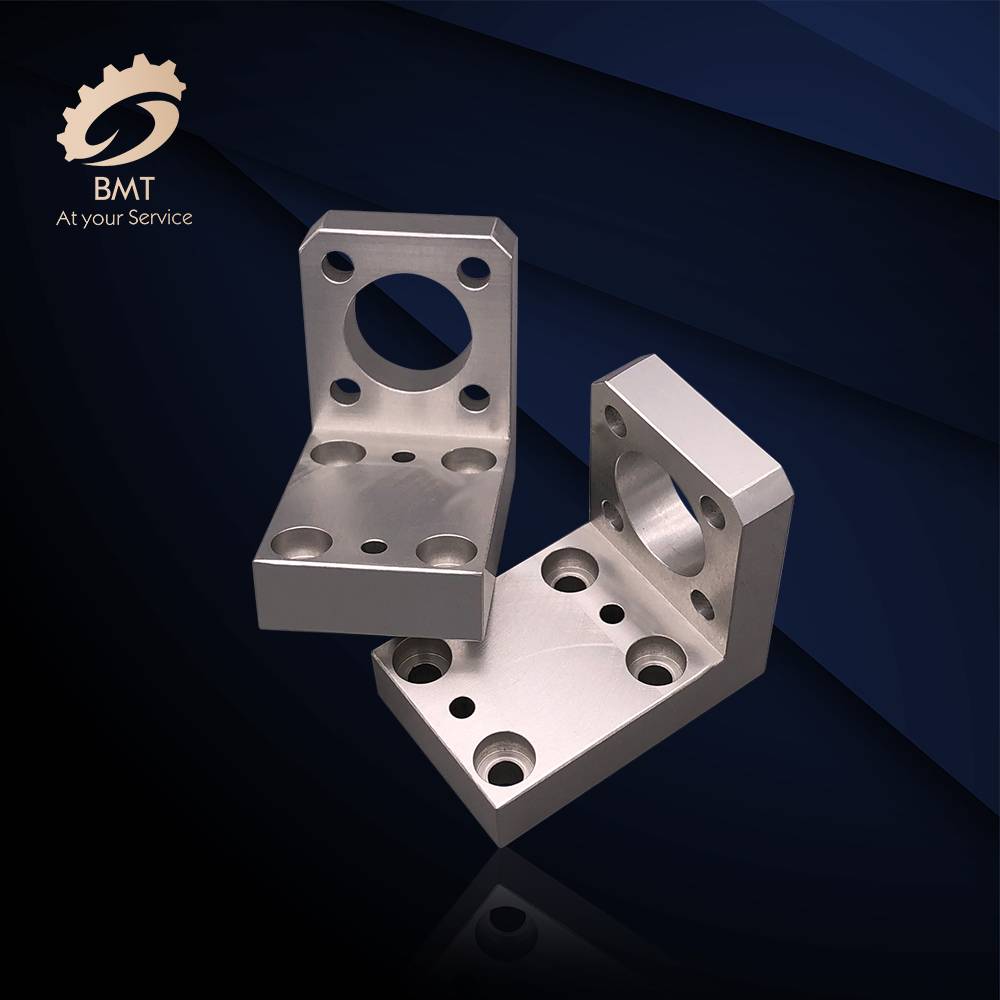

Lwm cov khoom peb ua

Txhawm rau dhau los ua theem ntawm kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab, muaj kev sib koom siab ntau thiab ntau tus kws tshaj lij ua haujlwm! Txhawm rau kom ncav cuag cov txiaj ntsig ntawm peb cov neeg yuav khoom, cov chaw muag khoom, lub neej thiab peb tus kheej rau Kev txo nqi loj Tuam Tshoj High Precision Hlau Stamping Parts Machining CNC Turned Parts Chaw tsim tshuaj paus, Thawj Tswj Hwm ntawm peb lub tuam txhab, nrog rau tag nrho cov neeg ua haujlwm, txais tos txhua tus neeg yuav khoom tuaj xyuas peb lub tuam txhab thiab tshuaj xyuas. Cia peb koom tes hauv tes ua kom muaj lub neej yav tom ntej zoo.

Kev txo nqi lojTuam Tshoj Machining CNC, Turned Parts Chaw tsim tshuaj paus, Peb tau ntseeg siab tias peb muaj peev xwm muab cov hauv kev rau koj thiab tej zaum yuav yog ib qho lag luam tseem ceeb ntawm koj. Peb tos ntsoov yuav ua haujlwm nrog koj sai sai. Kawm paub ntau ntxiv txog hom khoom muag uas peb ua haujlwm nrog lossis tiv tauj peb tam sim no ncaj qha nrog koj cov lus nug. Koj tuaj yeem tiv tauj peb txhua lub sijhawm!

Xa koj cov lus rau peb:

-

OEM / ODM Chaw tsim tshuaj paus Tuam Tshoj High Quality Titaniu ...

-

Kev xaiv loj rau Tuam Tshoj Chaw Tsim Tshuaj Txhuas ...

-

High Quality Professional Tuam Tshoj Hoobkas Hlau C ...

-

2019 High quality Tuam Tshoj Stainless hlau qhov chaw C ...

-

Tuam Tshoj OEM Tuam Tshoj ASTM A193 B7 Hex Bolt

-

Tuam Tshoj CNC Machining Qhov Chaw Anod...