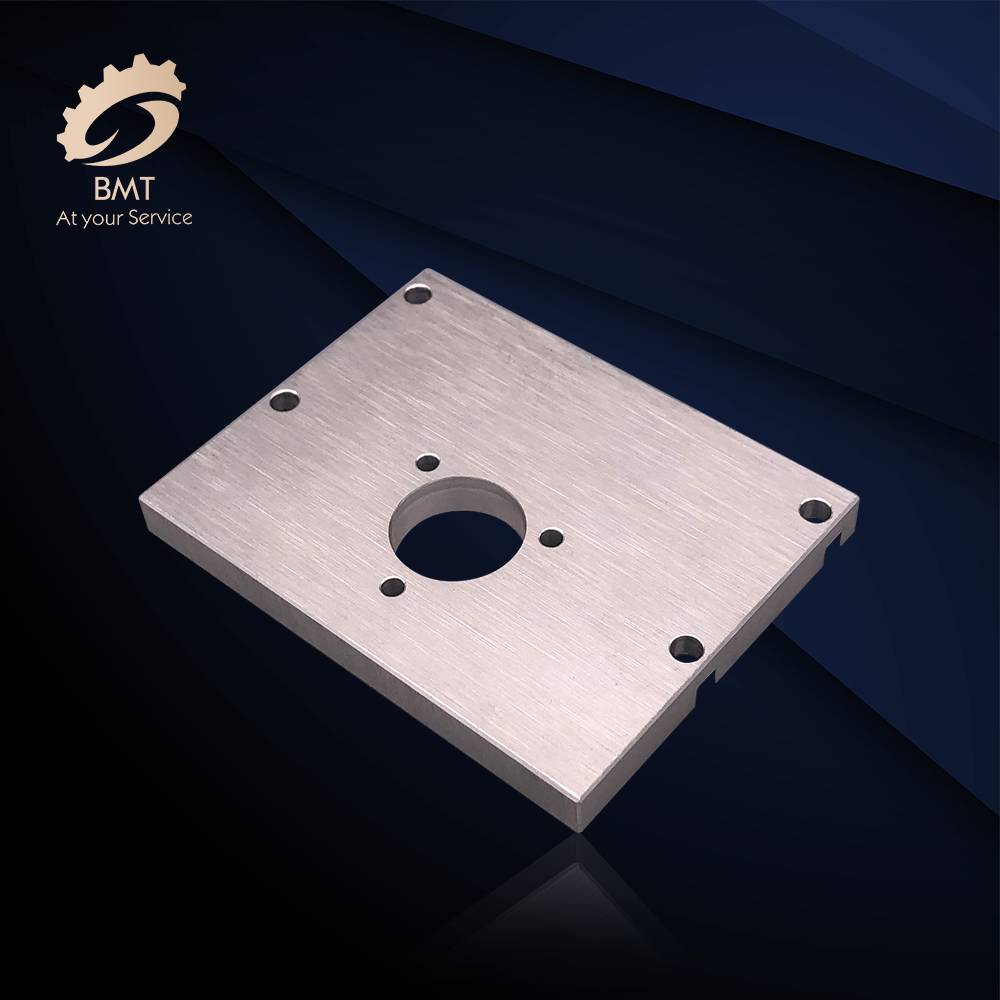

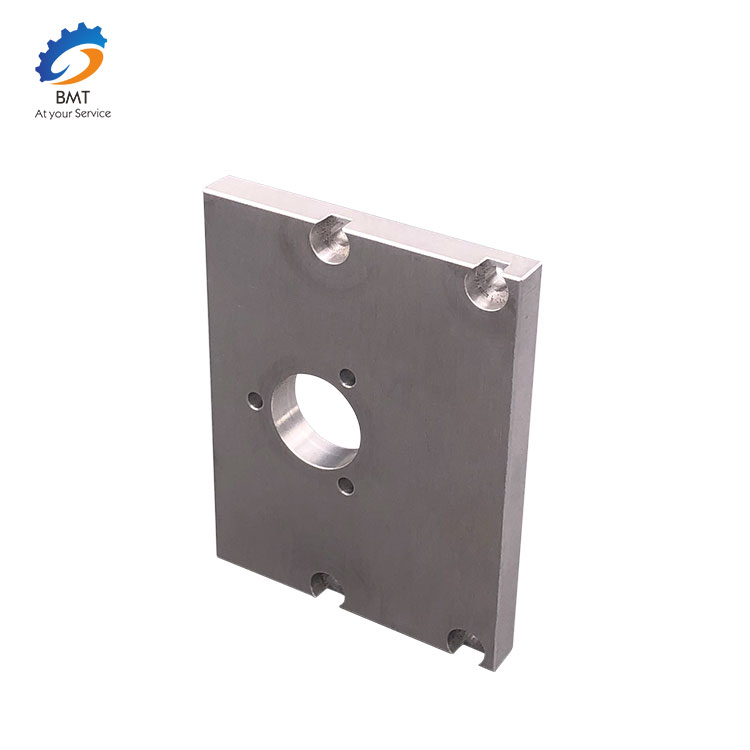

Ua raws li koj txoj kev xav ntawm "Tsim kev daws teeb meem zoo tshaj plaws thiab ua phooj ywg nrog cov neeg los ntawm thoob plaws lub ntiaj teb", peb ib txwm teeb tsa qhov kev xav tau ntawm cov neeg siv khoom pib nrog rau tus nqi pheej yig Tuam Tshoj Precision Machining Part of Cu Copper Brass Flange, Txais tos kom muab tso rau hauv muab kev sib txuas mus ntev nrog peb. Tus nqi zoo tshaj plaws rau kev ua haujlwm siab zoo hauv Suav teb.

Ua raws li koj txoj kev xav ntawm "Tsim cov kev daws teeb meem zoo tshaj plaws thiab ua phooj ywg nrog cov neeg los ntawm thoob plaws lub ntiaj teb", peb ib txwm teeb tsa lub siab nyiam ntawm cov neeg siv khoom pib nrog rauTuam Tshoj tooj liab Flange, Cu Flange, Peb pawg kws tshaj lij engineering yuav ib txwm npaj los pab koj rau kev sab laj thiab tawm tswv yim. Peb kuj tseem tuaj yeem muab cov qauv dawb rau koj kom tau raws li koj qhov yuav tsum tau ua. Kev siv zog zoo tshaj plaws yuav raug tsim los muab cov kev pabcuam zoo tshaj plaws thiab cov khoom rau koj. Rau txhua tus neeg uas xav txog peb lub tuam txhab thiab cov khoom muag, koj yuav tsum tiv tauj peb los ntawm kev xa email rau peb lossis tiv tauj peb sai. Raws li kev paub txog peb cov khoom muag thiab ruaj khov. ntau ntau, koj tuaj yeem tuaj rau peb lub Hoobkas kom paub txog nws. Peb yeej ib txwm txais tos qhua los ntawm thoob plaws lub ntiaj teb no los ntawm peb lub lag luam los tsim kev lag luam kev sib raug zoo nrog peb. Thov koj xav tiv tauj peb rau kev lag luam thiab peb ntseeg tias peb tau npaj los qhia txog kev ua lag luam sab saum toj nrog rau tag nrho peb cov tub lag luam.

Yam uas cuam tshuam rau qhov nyuaj ntawm ib feem

- Qhov Loj

Qhov loj ib leeg tsis txiav txim siab qhov nyuaj, tab sis tuaj yeem yog qhov tseem ceeb. Nco ntsoov, qee zaus qhov loj ntawm cov phiaj xwm tsis yooj yim dua li qhov me me, ntau qhov sib txawv. Tsis tas li, xav txog qhov loj ntawm tus kheej nta, vim qhov no cuam tshuam qhov loj ntawm cov cuab yeej txiav uas yuav siv tau. Lub cuab yeej loj dua, kev kub ceev txiav tuaj yeem tshem tawm cov khoom sai dua, txo lub sijhawm ua haujlwm.

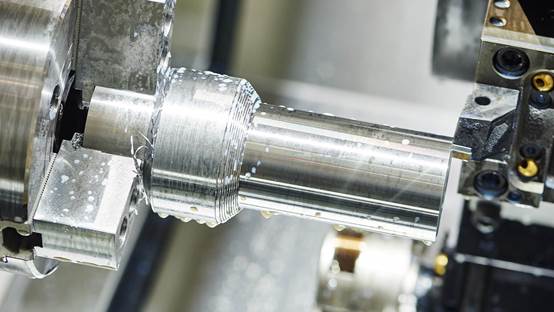

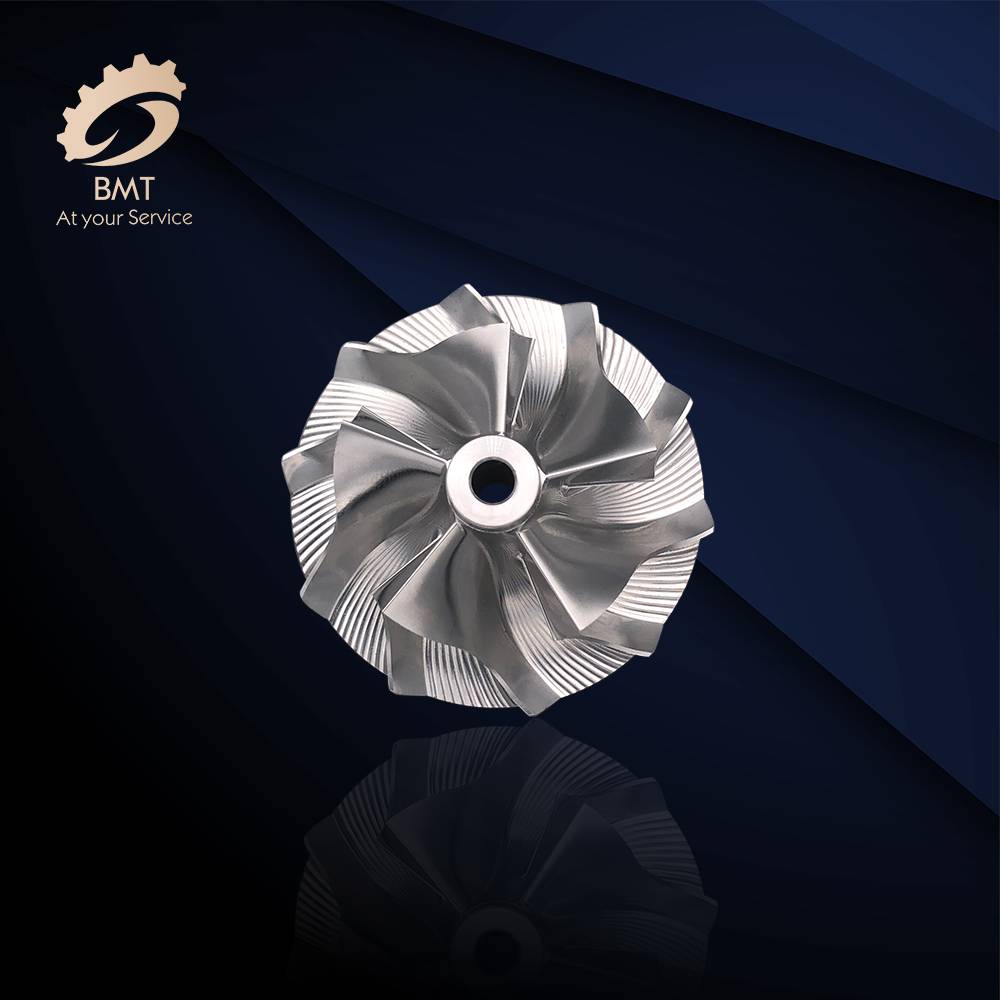

- Kev ua ib feem

Tus naj npawb ntawm kev ua haujlwm, kev cuam tshuam thiab kev txheeb xyuas xav tau ntawm ib feem tseem yuav cuam tshuam rau qhov nyuaj. Nyob ntawm cov duab geometry, tiav thiab tolerances thiab lwm yam, qhov kev txiav txim ntawm kev ua haujlwm yuav nyuaj, siv sijhawm ntev thiab nthuav dav. Piv txwv li, ib qho nyuaj yuav xav tau ntau qhov kev hloov kho dua tshiab thiab kev cuam tshuam ntawm phau ntawv. Qee lub sij hawm, 5 axis lossis lub tshuab tig tig yuav yog lub tshuab tsim nyog tshaj plaws, piv txwv li, yog tias nws raug nqi tsim khoom lossis xav tau cov nqi siv nyiaj tsawg dua.

- Qhov kam rau ua

Qhov kev kam rau siab tuaj yeem cuam tshuam qhov kev xaiv ntawm CNC tshuab siv thiab tuaj yeem cuam tshuam rau tus nqi thiab lub sijhawm ua haujlwm. Qhov ua tau zoo siab ntev kuj cuam tshuam los ntawm cov khoom siv, machining ceev thiab cov cuab yeej. Cias muab, qhov nruj dua qhov kam rau ua, qhov ntau koj feem yuav raug nqi. Kev kam rau siab dua tso cai rau kev txiav txim siab ntau dua, tab sis kuj tseem yuav muaj cov txheej txheem ntxiv, kev ua haujlwm, thiab cov cuab yeej thiab cov tshuab, yog li ntxiv rau tus nqi.

Hom kev ua tiav

- Bead Blasting

Bead Blasting cuam tshuam nrog kev tshem tawm ntawm qhov chaw tso nyiaj lossis qhov tsis zoo ntawm ib feem kom muaj kev sib txuam ntau dua, ua kom tiav. Cov hlaws zoo li cov hlaws dai kom zoo ib yam thiab feem ntau siv los muab matt tiav. Cov hlaws zoo nkauj kuj tseem siv tau rau ntau qhov zoo li satin lossis npub tiav.

- Anodized tiav

Anodized tiav muab cov txheej txheem hnav-tiv taus, feem ntau muaj nyob rau hauv ntau xim. Anodizing feem ntau yog pob tshab, thiab txheej txheej feem ntau nyias yog li nco ntsoov xav txog CNC Tshuab cov cim ntawm qhov chaw.

- Raws li machined

Lwm qhov kawg yuav tawm ntawm qhov chaw roughness raws li cov khoom yog machined. Qhov kev pabcuam roughness raug txiav txim siv Ra tus nqi. Feem ntau qhov roughness ntawm CNC machined qhov chaw yog Ra 1.6-3.2µm.

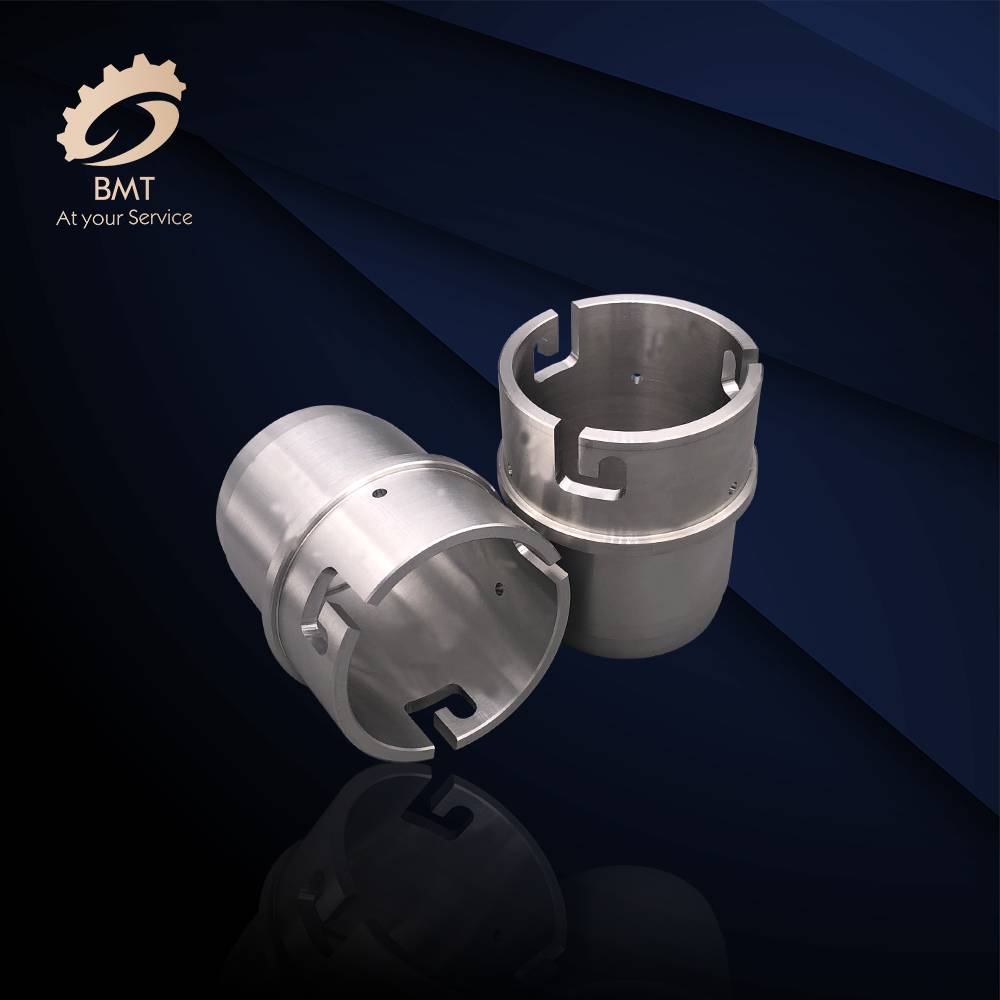

Product Description

Complexity ntawm ib feem

Complexity ntawm ib feem

Ua raws li koj txoj kev xav ntawm "Tsim kev daws teeb meem zoo tshaj plaws thiab ua phooj ywg nrog cov neeg los ntawm thoob plaws lub ntiaj teb", peb ib txwm teeb tsa qhov kev xav tau ntawm cov neeg siv khoom pib nrog rau tus nqi pheej yig Tuam Tshoj Precision Machining Part of Cu Copper Brass Flange, Txais tos kom muab tso rau hauv muab kev sib txuas mus ntev nrog peb. Tus nqi zoo tshaj plaws rau kev ua haujlwm siab zoo hauv Suav teb.

Ua raws li koj txoj kev xav ntawm "Tsim kev daws teeb meem zoo tshaj plaws thiab ua phooj ywg nrog cov neeg los ntawm thoob plaws lub ntiaj teb", peb ib txwm teeb tsa qhov kev xav tau ntawm cov neeg siv khoom pib nrog rau tus nqi pheej yig Tuam Tshoj Precision Machining Part of Cu Copper Brass Flange, Txais tos kom muab tso rau hauv muab kev sib txuas mus ntev nrog peb. Tus nqi zoo tshaj plaws rau kev ua haujlwm siab zoo hauv Suav teb.

Tus nqi pheej yigTuam Tshoj tooj liab Flange, Cu Flange, Peb pawg kws tshaj lij engineering yuav ib txwm npaj los pab koj rau kev sab laj thiab tawm tswv yim. Peb kuj tseem tuaj yeem muab cov qauv dawb rau koj kom tau raws li koj qhov yuav tsum tau ua. Kev siv zog zoo tshaj plaws yuav raug tsim los muab cov kev pabcuam zoo tshaj plaws thiab cov khoom rau koj. Rau txhua tus neeg uas xav txog peb lub tuam txhab thiab cov khoom muag, koj yuav tsum tiv tauj peb los ntawm kev xa email rau peb lossis tiv tauj peb sai. Raws li kev paub txog peb cov khoom muag thiab ruaj khov. ntau ntau, koj tuaj yeem tuaj rau peb lub Hoobkas kom paub txog nws. Peb yeej ib txwm txais tos qhua los ntawm thoob plaws lub ntiaj teb no los ntawm peb lub lag luam los tsim kev lag luam kev sib raug zoo nrog peb. Thov koj xav tiv tauj peb rau kev lag luam thiab peb ntseeg tias peb tau npaj los qhia txog kev ua lag luam sab saum toj nrog rau tag nrho peb cov tub lag luam.

Xa koj cov lus rau peb:

-

Dawb qauv rau Tuam Tshoj CNC Machining Aluminium Pr ...

-

Hauv qab nqe Tuam Tshoj Customized High Precision Ma ...

-

Taag Competitive Nqe Tuam Tshoj Custom Machining / ...

-

Txhim khu kev qha Supplier Fabrication Hlau Txee / Box ...

-

Lag luam wholesale OEM / ODM Tuam Tshoj Chaw tsim tshuaj paus Accu ...

-

Tuam Tshoj CNC Machining Qhov Chaw Anod...