Peb xav tias cov neeg siv khoom xav li cas, qhov nrawm nrawm los ua haujlwm hauv kev txaus siab ntawm tus neeg siv khoom txoj haujlwm ntawm lub hauv paus ntsiab lus, tso cai rau kev ua haujlwm zoo dua qub, txo cov nqi ua haujlwm, cov nqi tsim nyog ntxiv, yeej cov neeg siv khoom tshiab thiab yav dhau los kev txhawb nqa thiab kev lees paub rau Tuam Tshoj Cov Khoom Tshiab Tuam Tshoj H11 Rolled Forging TitaniumMandrel Bars rau Yeeb Nkab, Peb ib txwm muab cov khoom zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws rau feem ntau ntawm cov neeg siv khoom lag luam thiab cov tub luam. Zoo siab txais tos tuaj koom nrog peb, cia peb tsim kho tshiab ua ke, thiab ya npau suav.

Peb xav tias cov neeg siv khoom xav li cas, qhov nrawm nrawm los ua haujlwm hauv kev txaus siab ntawm tus neeg siv khoom txoj haujlwm ntawm lub hauv paus ntsiab lus, tso cai rau kev ua haujlwm zoo dua qub, txo cov nqi ua haujlwm, cov nqi tsim nyog ntxiv, yeej cov neeg siv khoom tshiab thiab yav dhau los kev txhawb nqa thiab kev lees paub rauTuam Tshoj Mandrel Bars, Mandrel Bars rau Yeeb Nkab, peb vam thiab cia siab tias yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam mus sij hawm ntev nrog koj lub tuam txhab muaj txiaj ntsig los ntawm lub sijhawm no, raws li kev sib luag, kev sib raug zoo thiab kev lag luam yeej-yeej los ntawm tam sim no mus rau yav tom ntej. "Koj qhov kev txaus siab yog peb txoj kev zoo siab".

Titanium thiab Titanium Alloy Bars

Titanium alloys tuaj yeem muab faib ua peb pawg raws li qhov muaj pes tsawg leeg ntawm cov theem: α alloy, (α + β) alloy thiab β alloy, uas tau hais los ntawm TA, TC thiab TB hauv Suav teb.

① Lub α alloy muaj qee yam ntawm cov ntsiab lus nrog α theem ruaj khov thiab feem ntau yog tsim los ntawm α theem hauv lub xeev sib npaug. α alloys muaj lub ntiajteb txawj nqus me me, zoo thermal zog, zoo weldability thiab zoo heev corrosion kuj. Qhov tsis zoo yog qhov tsis muaj zog ntawm chav sov, thiab lawv feem ntau yog siv los ua cov khoom siv hluav taws xob thiab cov khoom tiv thaiv corrosion. Feem ntau, α alloys tuaj yeem muab faib ua tag nrho α alloys (Ta7), ze li ntawm α alloys (Ti-8Al-1Mo-1V) thiab α alloys nrog ob peb lub tebchaw (Ti-2.5Cu).

② (α + β) alloy muaj qee yam ntawm cov ntsiab lus ruaj khov α theem thiab β theem, thiab cov microstructure ntawm cov hlau nyob hauv lub xeev sib npaug yog α theem thiab β theem.The (α + β) alloy muaj lub zog nruab nrab thiab tuaj yeem ua tau. ntxiv dag zog los ntawm kev kho cua sov, tab sis lub weldability tsis zoo.(α+ β) alloys tau dav siv, thiab cov zis ntawm Ti-6Al-4V alloys nyiaj ntau tshaj ib nrab ntawm tag nrho cov ntaub ntawv titanium.

① β alloy muaj ntau cov ntsiab lus ruaj khov β theem, siab kub β theem tuaj yeem khaws cia rau hauv chav tsev kub.β alloy tuaj yeem muab faib ua cov cua sov kho β alloy (metastable β alloy thiab ze li ntawm metastable β alloy) thiab kub ruaj khov β alloy. Lub tshav kub-kho tau β alloy tau zoo heev ductility nyob rau hauv lub xeev quenched thiab muaj peev xwm ua tau lub zog tensile ntawm 130 ~ 140kgf / mm2 los ntawm kev laus kev kho mob.β alloys feem ntau yog siv raws li lub zog siab thiab siab toughness cov ntaub ntawv.Qhov tsis zoo yog qhov tseem ceeb, tus nqi siab, vuam tsis zoo. kev ua tau zoo, machining nyuaj.

Citation qauv

1: GB 228 Metallic tensile xeem txoj kev

2: GB / T 3620.1 Titanium thiab titanium alloy qib thiab tshuaj muaj pes tsawg leeg

3: GB / T3620.2 titanium thiab titanium alloy ua cov khoom siv tshuaj lom neeg thiab muaj pes tsawg leeg tso cai sib txawv

GB 4698 Txoj kev rau tshuaj ntsuam xyuas ntawm titanium daim txhuam cev, titanium thiab titanium alloys

GB: GB/T2965-2007, GB/T13810, Q/BS5331-91

Txuj: ASTM B348, ASTM F136, ASTM F67, AMS4928

Kev xav tau

1: Cov tshuaj muaj pes tsawg leeg ntawm titanium thiab titanium alloy bar yuav tsum ua raws li cov kev cai ntawm GB / T 3620.1. Thaum rov kuaj dua, qhov tso cai sib txawv ntawm cov tshuaj muaj pes tsawg leeg yuav tsum ua raws li cov kev cai ntawm GB / T 3620.2.

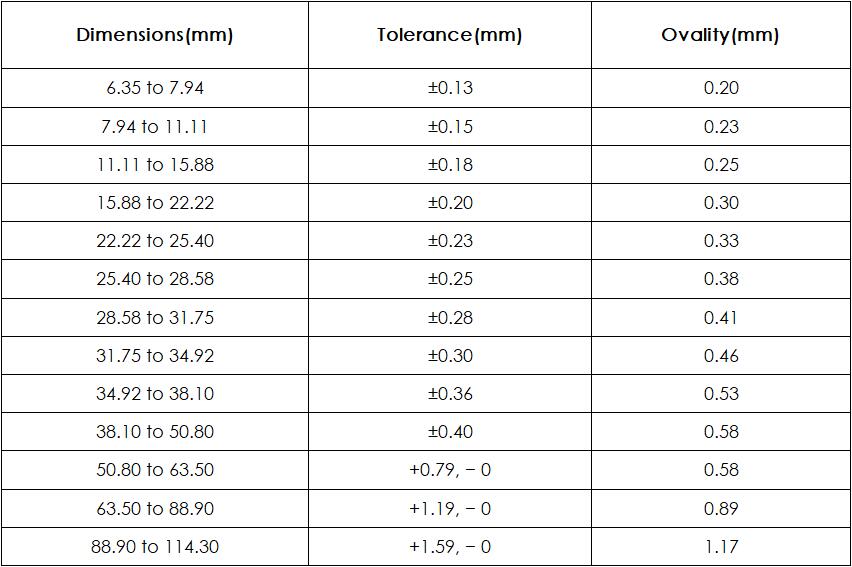

2: Txoj kab uas hla lossis sab ntev ntawm qhov kub-ua haujlwm thiab nws qhov kev sib txawv ntawm qhov tso cai yuav tsum ua raws li cov kev cai hauv Table 1.

3: Tom qab ua haujlwm kub, qhov sib txawv ntawm qhov sib txawv ntawm qhov sib txawv ntawm qhov txias txias yuav tsum ua raws li cov kev cai hauv Table 2 tom qab dov (sib tsoo) polished bar thiab txias dov.

4: Tom qab ua haujlwm kub los ntawm lub tsheb (sib tsoo) lub teeb bar ntawm roundness yuav tsum tsis txhob ntau tshaj li ib nrab ntawm nws qhov loj kam rau ua.

5: qhov ntev ntawm qhov ntev ntawm lub xeev ua tiav yog 300-6000mm, qhov ntev ntawm indeterminate ntev ntawm lub xeev annealed bar yog 300-2000mm, thiab qhov ntev ntawm qhov ntev ntev los yog ob chav ntev yuav tsum nyob rau hauv qhov ntau ntawm indeterminate ntev. .Qhov tso cai sib txawv ntawm qhov ntev ntev yog +20mm; Qhov ntev ntawm ob qhov ntev yuav tsum tau suav nrog hauv qhov txiav nyiaj ntawm qhov bar, thiab txhua qhov txiav yuav tsum yog 5 hli. Qhov ntev ntawm qhov ruaj khov los yog qhov ntev ntawm ob qhov ntev yuav tsum tau teev nyob rau hauv daim ntawv cog lus.

Specifications: dov ¢8.0-40mm × L; Forging ¢40-150 - mm x L

Metallographic qauv: ntshiab titanium grain loj tsis tsawg tshaj li qib 5, TC4 titanium alloy nyob rau hauv kab nrog A1-A9.

Nto: dub nto, polished nto, polished nto (H11, H9, H8)

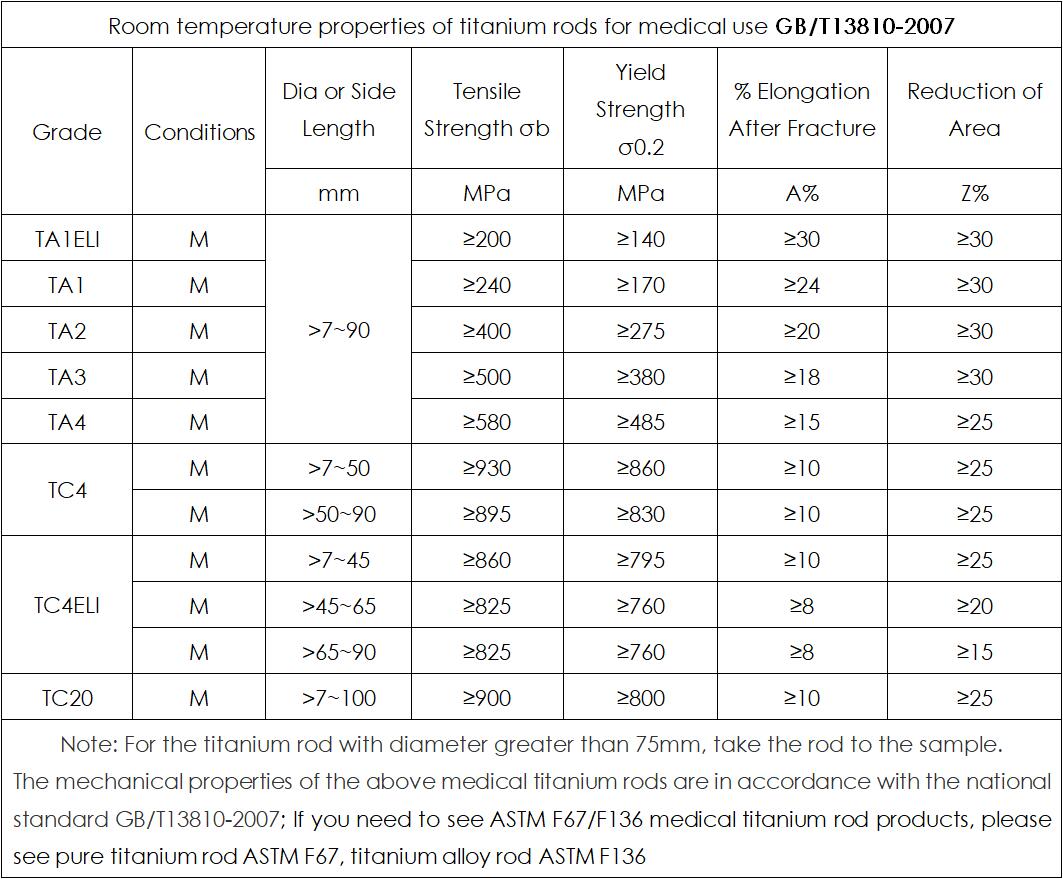

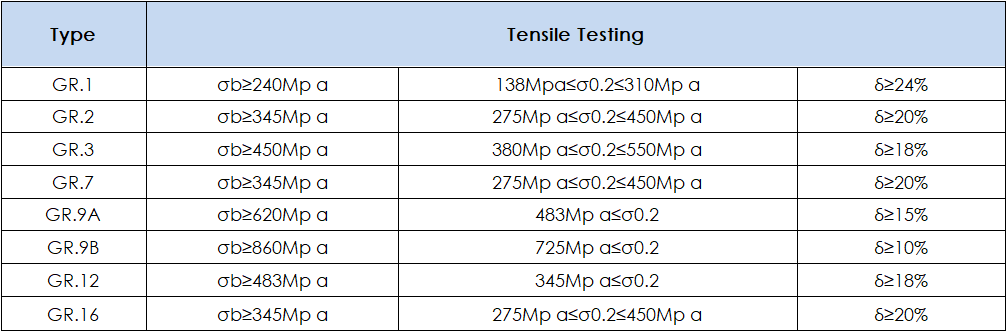

Kev ua haujlwm ntawm kev kho mob titanium pas nrig (siv tus qauv: GB / T13810-2007, ASTM F67 / F136).

Peb perennially tsim thiab xa tawm ASTM tus qauv titanium bar thiab Suav Standard (GB) tus qauv titanium bar, thiab titanium bar ntawm kev sib pom zoo qauv.

Ua nyob rau ntawm ob peb lub tuam txhab uas tuaj yeem paub txog kev tswj hwm zoo ntawm tag nrho cov txheej txheem tsim khoom, peb ua tiav kev tswj hwm nruj txhua txoj hauv kev los ntawm cov khoom siv raw smelting ntawm titanium daim txhuam cev mus rau cov khoom tiav.

Muaj qhov zoo tshaj plaws thiab tsis muaj kev saib xyuas thiab kev pabcuam, peb muag cov khoom suav nrog kev kho mob titanium bar, titanium polishing bar thiab titanium alloy bar thoob plaws ntiaj teb. Peb tau dhau los ua ib tus neeg xa khoom loj tshaj plaws thiab xa tawm ntawm titanium bar hauv Suav teb.

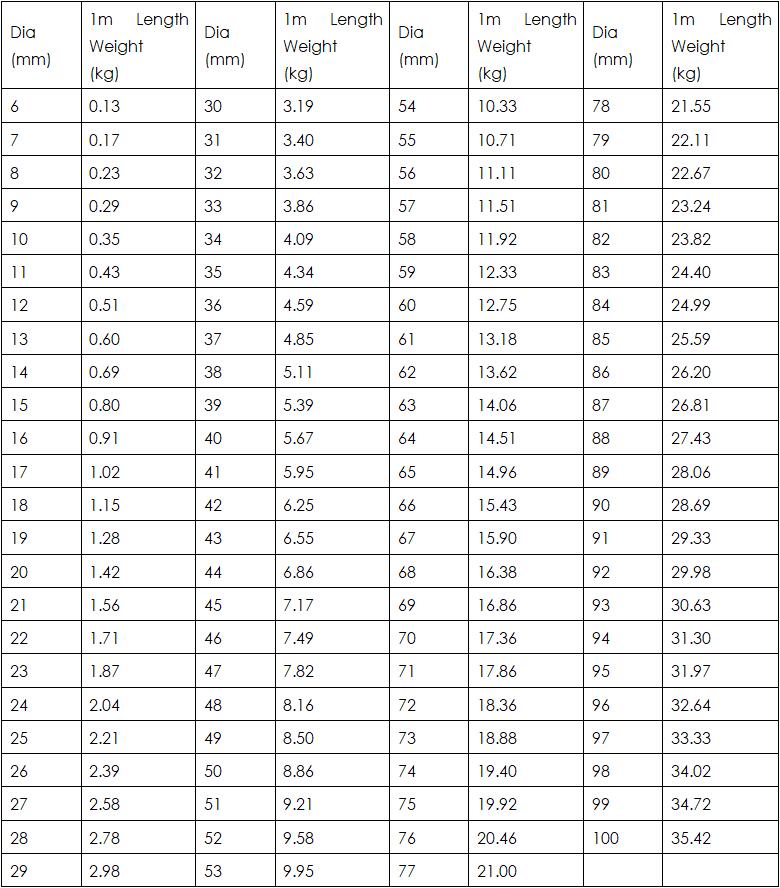

Qhov ntau thiab tsawg: Dia 6-200mm x Max 6000mm

Chav ntsuas kub ntawm titanium rods rau kev kho mob siv GB / T13810-2007:

Qhov Loj Peb tau ua:

Dimensions, Tolerance thiab Ovality Range:

Muaj cov khoom siv tshuaj lom neeg muaj pes tsawg leeg

Muaj cov khoom siv tshuaj lom neeg muaj pes tsawg leeg

Kev tshuaj ntsuam xyuas:

- NDT Test

- Ultrasonic Test

- LDP Test

- Ferroxyl Test

Productivity (Max thiab Min npaum li cas ntawm Order):Unlimited, raws li kev txiav txim.

Lub Sijhawm Lead:Lub sijhawm ua haujlwm dav dav yog 30 hnub. Txawm li cas los xij, nws nyob ntawm tus nqi ntawm qhov kev txiav txim accringly.

Kev thauj mus los:Txoj kev dav dav ntawm kev thauj mus los yog Hiav Txwv, los ntawm Cua, los ntawm Express, los ntawm Tsheb ciav hlau, uas yuav tsum tau xaiv los ntawm cov neeg siv khoom.

Ntim:

- Cov yeeb nkab kawg yuav tsum tau tiv thaiv nrog lub kaus mom yas lossis cardboard.

- Tag nrho cov fittings yuav tsum tau ntim los tiv thaiv qhov xaus thiab tig ntsej muag.

- Tag nrho lwm cov khoom yuav raug ntim los ntawm cov ntaub qhwv ntsej muag thiab cov hnab yas thiab cov ntaub ntawv plywood.

- Txhua yam ntoo siv rau ntim yuav tsum tsim nyog los tiv thaiv kev sib kis los ntawm kev sib cuag nrog cov cuab yeej tuav.

Peb xav tias cov neeg siv khoom xav li cas, qhov nrawm nrawm los ua haujlwm hauv kev txaus siab ntawm tus neeg siv khoom txoj haujlwm ntawm lub hauv paus ntsiab lus, tso cai rau kev ua haujlwm zoo dua qub, txo cov nqi ua haujlwm, cov nqi tsim nyog ntxiv, yeej cov neeg siv khoom tshiab thiab yav dhau los kev txhawb nqa thiab kev lees paub rau Tuam Tshoj Cov Khoom Tshiab Tuam Tshoj H11 Rolled Forging Titanium Mandrel Bars rau Yeeb Nkab, Peb ib txwm muab cov khoom lag luam zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws rau feem ntau ntawm cov neeg siv khoom lag luam thiab cov neeg lag luam. Zoo siab txais tos tuaj koom nrog peb, cia peb tsim kho tshiab ua ke, thiab ya npau suav.

Tuam Tshoj Cov Khoom TshiabTuam Tshoj Mandrel Bars, Mandrel Bars rau Yeeb Nkab, peb ua siab dawb cia siab tias yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam ntev nrog koj lub tuam txhab hwm los ntawm lub sijhawm no, raws li kev sib luag, kev sib nrig sib pab thiab kev lag luam yeej-yeej los ntawm tam sim no mus rau yav tom ntej. "Koj qhov kev txaus siab yog peb txoj kev zoo siab".