Titanium Machining nyuaj

(1) Lub deformation coefficient yog me me:

Qhov no yog ib qho tseem ceeb feature nyob rau hauv machining ntawm titanium alloy cov ntaub ntawv. Nyob rau hauv tus txheej txheem ntawm kev txiav, qhov chaw sib cuag ntawm lub nti thiab lub ntsej muag rake yog loj heev, thiab cov hlab ntsha ntawm lub nti ntawm lub ntsej muag rake ntawm lub cuab yeej yog loj dua li ntawm cov khoom siv dav dav. Xws li kev taug kev mus ntev yuav ua rau cov cuab yeej hnav hnyav, thiab kev sib txhuam kuj tshwm sim thaum taug kev, uas ua rau qhov kub ntawm cov cuab yeej nce.

(2) Kub txiav:

Ntawm ib sab, qhov me me deformation coefficient tau hais los saum no yuav ua rau ib feem ntawm qhov kub thiab txias. Lub ntsiab nam ntawm lub siab txiav kub nyob rau hauv lub titanium alloy txiav txheej txheem yog hais tias lub thermal conductivity ntawm titanium alloy yog tsawg heev, thiab qhov ntev ntawm kev sib cuag ntawm lub nti thiab lub ntsej muag rake ntawm lub cuab tam yog luv.

Raws li kev cuam tshuam ntawm cov xwm txheej no, cov cua sov tsim tawm thaum lub sij hawm txiav yog qhov nyuaj rau kev xa tawm, thiab nws feem ntau accumulates nyob ze ntawm lub ntsis ntawm lub cuab yeej, ua rau lub zos kub siab dhau.

(3) Lub thermal conductivity ntawm titanium alloy yog tsawg heev:

Lub tshav kub generated los ntawm kev txiav yog tsis yooj yim dissipated. Cov txheej txheem tig ntawm titanium alloy yog cov txheej txheem ntawm kev ntxhov siab loj thiab cov kab mob loj, uas yuav ua kom muaj cua sov ntau, thiab cov cua kub siab uas tsim tawm thaum lub sijhawm ua haujlwm tsis tuaj yeem ua tau zoo. Ntawm cov hniav, qhov kub nce siab, cov hniav softens, thiab cov cuab yeej hnav yog nrawm.

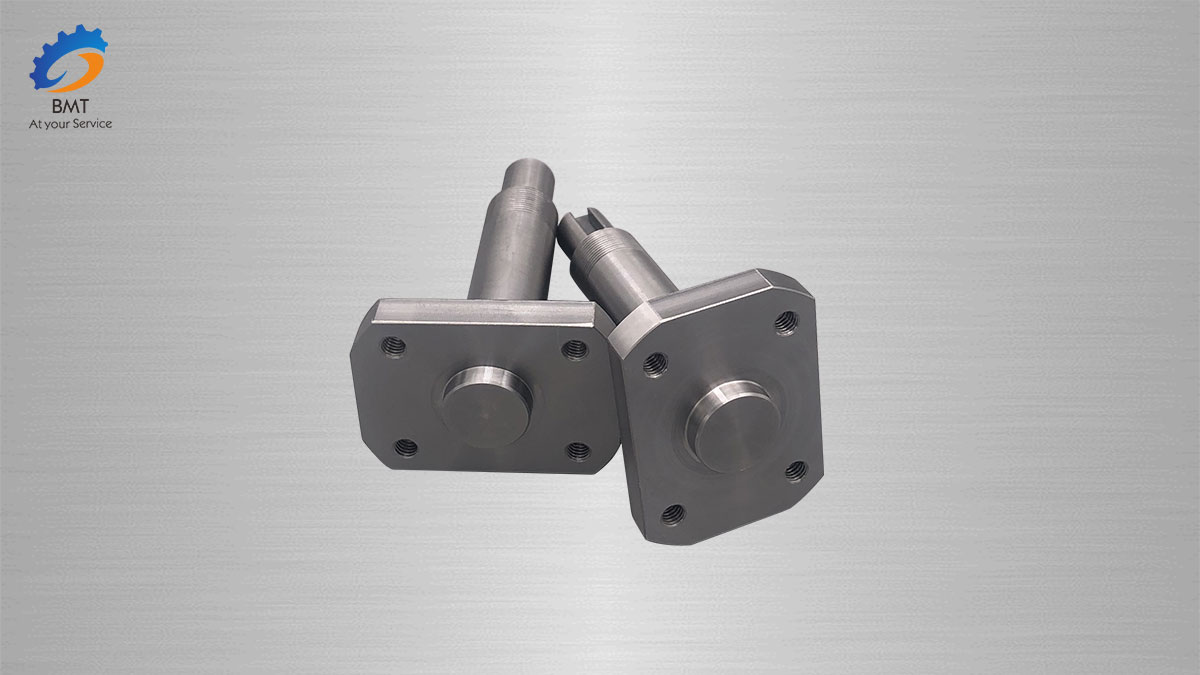

Lub zog tshwj xeeb ntawm titanium alloy cov khoom yog siab heev ntawm cov khoom siv hlau. Nws lub zog yog piv rau cov hlau, tab sis nws qhov hnyav tsuas yog 57% ntawm cov hlau. Tsis tas li ntawd, titanium alloys muaj cov yam ntxwv ntawm me me lub ntiajteb txawj nqus, siab thermal zog, zoo thermal stability thiab corrosion kuj, tab sis titanium alloy cov ntaub ntawv yog ib qho nyuaj rau txiav thiab muaj tsawg ua efficiency. Yog li ntawd, yuav ua li cas kov yeej qhov nyuaj thiab tsis tshua muaj txiaj ntsig ntawm titanium alloy ua tau ib txwm yog qhov teeb meem ceev kom daws tau.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes