Titanium Machining nyuaj

Lub thermal conductivity ntawm titanium alloy yog me me, yog li qhov kub thiab txias yog siab heev thaum ua titanium alloy. Nyob rau hauv tib lub sijhawm, qhov ntsuas kub ntawm kev ua TC4 [i] yog ntau dua ob npaug ntawm No. 45 steel, thiab cov cua sov tsim tawm thaum lub sijhawm ua haujlwm yog qhov nyuaj dhau los ntawm kev ua haujlwm. Tso tawm; cov cua sov tshwj xeeb ntawm titanium alloy yog me me, thiab qhov kub hauv zos nce sai sai thaum ua haujlwm. Yog li ntawd, qhov kub ntawm lub cuab yeej yog siab heev, lub cuab yeej yog sharply hnav, thiab lub neej kev pab cuam yog txo.

Qhov tsis tshua muaj elastic modulus ntawm titanium alloy [ii] ua rau lub tshuab ua kom lub ntsej muag ua rau lub caij nplooj ntoos hlav, tshwj xeeb tshaj yog cov machining ntawm nyias-walled qhov chaw yog qhov hnyav dua, uas yooj yim ua rau muaj kev sib txhuam ntawm cov flank thiab machined nto, yog li hnav cov cuab yeej thiab chipping. hniav.

Titanium alloy muaj cov tshuaj lom neeg muaj zog, thiab nws yooj yim rau kev cuam tshuam nrog oxygen, hydrogen thiab nitrogen ntawm qhov kub thiab txias, uas ua rau nws muaj zog thiab txo nws cov plasticity. Cov txheej txheem oxygen nplua nuj tsim thaum lub sij hawm cua sov thiab forging ua rau machining nyuaj.

Machining cov ntsiab lus ntawm titanium alloy cov ntaub ntawv[1-3]

Nyob rau hauv cov txheej txheem machining, cov khoom siv tau xaiv, txiav cov xwm txheej thiab lub sijhawm txiav yuav cuam tshuam rau kev ua haujlwm thiab kev lag luam ntawm titanium alloy txiav.

1. Xaiv cov khoom siv tsim nyog

Raws li cov khoom, cov txheej txheem ua thiab kev ua haujlwm ntawm cov ntaub ntawv titanium alloy, cov khoom siv yuav tsum raug xaiv kom tsim nyog. Cov cuab yeej siv yuav tsum tau xaiv ntau dua siv, tus nqi qis, hnav tsis kam, siab thermal hardness, thiab muaj toughness txaus.

2. Txhim kho kev txiav

Lub rigidity ntawm lub tshuab-fixture-tool system yog zoo dua. Kev tshem tawm ntawm txhua qhov ntawm lub tshuab cuab yeej yuav tsum tau kho kom zoo, thiab lub radial runout ntawm spindle yuav tsum me me. Lub clamping ua hauj lwm ntawm lub fixture yuav tsum ruaj thiab nruj txaus. Kev txiav ib feem ntawm lub cuab yeej yuav tsum yog luv li sai tau, thiab lub thickness ntawm lub txiav ntug yuav tsum tau nce ntau npaum li sai tau thaum lub nti kam rau ua txaus los txhim kho lub zog thiab rigidity ntawm lub cuab tam.

3. Kev kho cua sov tsim nyog ntawm cov khoom ua tiav

Cov khoom thiab cov qauv metallographic ntawm titanium alloy cov ntaub ntawv raug hloov pauv los ntawm kev kho cua sov [iii], txhawm rau txhim kho kev ua haujlwm ntawm cov ntaub ntawv.

4. Xaiv tus nqi txiav tsim nyog

Txiav ceev yuav tsum tsawg. Vim hais tias kev txiav ceev muaj qhov cuam tshuam zoo rau qhov kub ntawm qhov txiav ntug, qhov siab dua qhov txiav ceev, qhov nce siab ntawm qhov kub ntawm qhov txiav, thiab qhov kub ntawm qhov txiav ncaj qha cuam tshuam rau lub neej ntawm cov cuab yeej, yog li nws yog tsim nyog los xaiv qhov tsim nyog txiav ceev.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

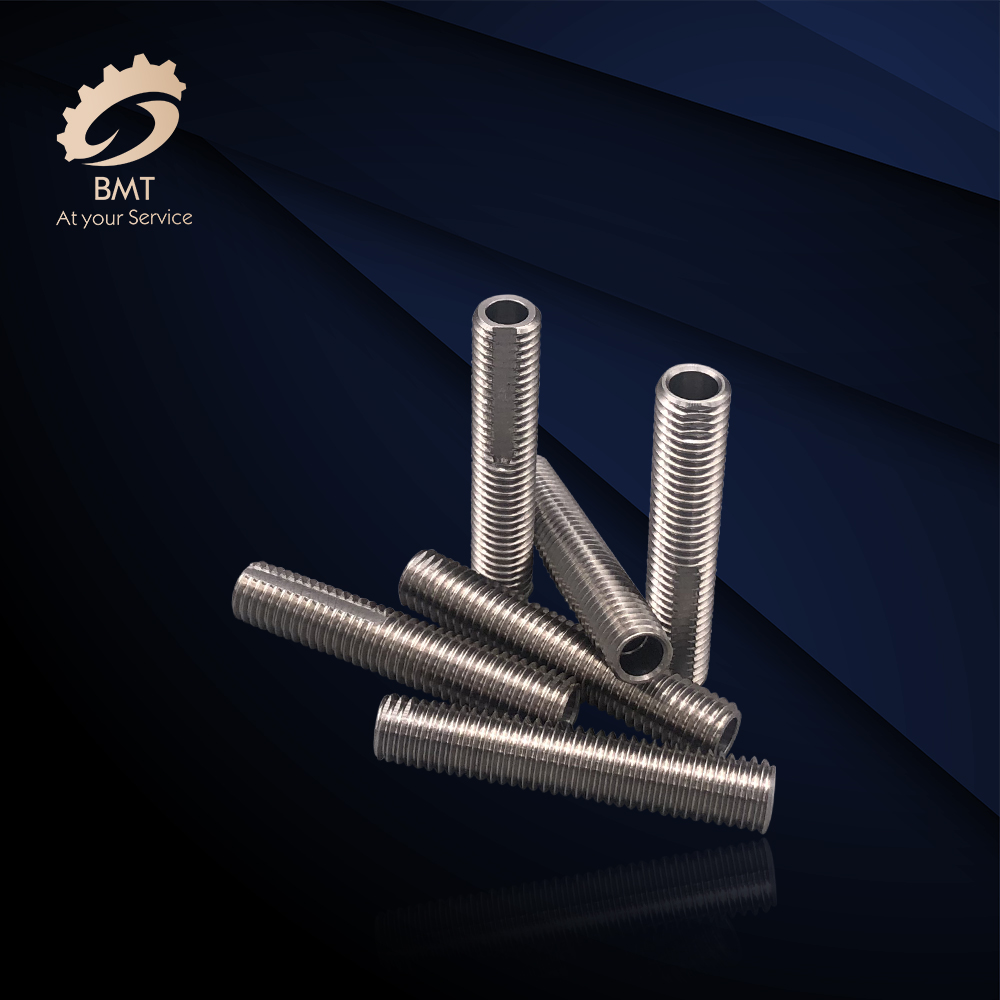

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes