Titanium thiab Titanium Alloy Forgings

Titanium thiab titanium alloys muaj qhov zoo ntawm qhov ceev, muaj lub zog tsis zoo thiab siv tau zoo siv hauv ntau thaj teb.

Titanium forging yog ib txoj kev tsim uas siv cov quab yuam sab nraud rau titanium hlau blanks (tsis suav cov phaj) los tsim cov yas deformation, hloov qhov loj me, cov duab, thiab txhim kho kev ua haujlwm. Nws yog siv los tsim cov khoom siv kho tshuab, cov khoom ua haujlwm, cov cuab yeej lossis cov khoom seem. Tsis tas li ntawd, raws li tus qauv txav ntawm lub slider thiab ntsug thiab kab rov tav txav qauv ntawm lub slider (Rau forging ntawm slender qhov chaw, lubrication thiab txias, thiab forging ntawm high-ceev ntau lawm qhov chaw), lwm yam kev taw qhia ntawm lub zog yuav nce los ntawm siv cov khoom them nyiaj.

Cov txheej txheem saum toj no txawv, thiab qhov yuav tsum tau muaj zog forging, txheej txheem, kev siv cov khoom siv, cov zis, qhov ntev ntev, thiab lubrication thiab txias txoj kev kuj txawv. Cov yam tseem ceeb no kuj yog yam uas cuam tshuam rau qib ntawm automation.

Forging yog txheej txheem ntawm kev siv cov yas ntawm cov hlau kom tau txais cov txheej txheem tsim cov yas nrog cov duab thiab cov yam ntxwv ntawm qhov khoob nyob rau hauv qhov cuam tshuam los yog siab ntawm cov cuab yeej. Lub superiority ntawm forging ntau lawm yog hais tias nws muaj peev xwm tsis tsuas tau txais cov duab ntawm mechanical qhov chaw, tab sis kuj txhim kho lub internal qauv ntawm cov khoom thiab txhim kho cov neeg kho tshuab cov khoom ntawm mechanical qhov chaw.

1. Dawb Forging

Dawb forging feem ntau yog nqa tawm ntawm ob lub tiaj tuag lossis pwm yam tsis muaj kab noj hniav. Cov cuab yeej siv dawb forging yog qhov yooj yim hauv cov duab, hloov tau yooj yim, luv luv hauv kev tsim khoom lag luam thiab tus nqi qis. Txawm li cas los xij, kev siv zog ua haujlwm siab, kev ua haujlwm nyuaj, kev tsim khoom tsawg, qhov zoo ntawm forgings tsis siab, thiab cov nyiaj siv ua haujlwm loj. Yog li ntawd, nws tsuas yog tsim nyog siv thaum tsis muaj kev tshwj xeeb ntawm kev ua haujlwm ntawm cov khoom thiab cov khoom me me.

2. Qhib Tuag Forging (Tuag Forging nrog Burrs)

Qhov dawb paug yog deformed ntawm ob modules nrog kab noj hniav engraved, lub forging yog nyob rau hauv cov kab noj hniav, thiab cov hlau ntau dhau ntws tawm ntawm qhov nqaim qhov sib txawv ntawm ob qhov tuag, tsim burrs nyob ib ncig ntawm lub forging. Nyob rau hauv qhov tsis kam ntawm pwm thiab ib puag ncig burrs, cov hlau raug yuam kom nias rau hauv cov pwm kab noj hniav.

3. Kaw Tuag Forging (Tuag Forging yam tsis muaj Burrs)

Thaum lub sij hawm kaw tuag forging txheej txheem, tsis muaj transverse burrs perpendicular rau cov kev taw qhia ntawm tuag txav yog tsim. Cov kab noj hniav ntawm qhov kaw forging tuag muaj ob txoj haujlwm: ib qho yog rau kev tsim cov khoob, thiab lwm qhov yog rau kev taw qhia.

4. Extrusion Tuag Forging

Siv txoj kev extrusion rau tuag forging, muaj ob hom forging, forward extrusion thiab thim rov qab extrusion. Extrusion tuag forging tuaj yeem tsim ntau yam hollow thiab khoom seem, thiab tuaj yeem tau txais forgings nrog siab geometrical precision thiab denser nrog cov qauv.

5. Multi-Directional Tuag Forging

Nws yog nqa tawm ntawm ib tug multi-directional tuag forging tshuab. Ntxiv nrog rau ntsug xuas nrig ntaus thiab ntsaws txhaj tshuaj, ntau txoj kev tuag forging tshuab kuj muaj ob kab rov tav plungers. Nws ejector kuj tseem siv tau rau kev xuas nrig ntaus. Lub siab ntawm lub ejector yog siab dua li ntawm cov hydraulic xovxwm. Ua kom loj. Nyob rau hauv ntau txoj kev tuag forging, lub slider ua alternately thiab sib koom ua ke ntawm lub workpiece los ntawm ntsug thiab kab rov tav cov lus qhia, thiab ib los yog ntau tshaj perforation punches yog siv los ua cov hlau ntws tawm sab nraud ntawm qhov chaw ntawm kab noj hniav kom ua tiav lub hom phiaj ntawm kev sau cov khoom. kab noj hniav.

6. Faib Forging

Txhawm rau txhawm rau txhawm rau txhawm rau forging loj loj ntawm cov hydraulic siab uas twb muaj lawm, segmental tuag forging txoj kev xws li ntu tuag forging thiab shim phaj tuag forging tuaj yeem siv. Cov yam ntxwv ntawm ib feem tuag forging txoj kev yog ua cov txheej txheem forging los ntawm daim, ua ib feem ntawm ib lub sij hawm, yog li cov khoom yuav tsum tau tonnage yuav tsawg heev. Feem ntau hais lus, txoj kev no tuaj yeem siv los ua cov txheej txheem loj ntxiv rau ntawm qhov nruab nrab-qhov loj me hydraulic presses.

7. Isothermal Tuag Forging

Ua ntej forging, pwm yog rhuab mus rau qhov kub ntawm forging ntawm qhov dawb paug, thiab qhov kub ntawm cov pwm thiab qhov dawb paug tseem zoo ib yam thoob plaws hauv cov txheej txheem forging, thiaj li hais tias ib tug loj npaum li cas ntawm deformation yuav tau txais nyob rau hauv qhov kev txiav txim ntawm ib tug me me deformation quab yuam. . Isothermal tuag forging thiab isothermal superplastic tuag forging zoo sib xws, qhov txawv yog tias ua ntej tuag forging, qhov khoob yuav tsum tau superplasticized [i] kom nws muaj equiaxed nplej [ii].

Titanium alloy forging txheej txheem yog dav siv nyob rau hauv aviation thiab aerospace manufacturing (Isothermal Tuag Forging Txheej txheemtau siv nyob rau hauv zus tau tej cov cav qhov chaw thiab aircraft structural qhov chaw), thiab nws yog ua ntau thiab ntau nrov nyob rau hauv industrial sectors xws li tsheb, hluav taws xob, thiab ships.

Tam sim no, kev siv tus nqi ntawm cov khoom siv titanium yog qhov siab, thiab ntau lub teb chaws pej xeem tsis tau paub txog qhov ntxim nyiam ntawm titanium alloys. Nrog rau kev nce qib ntawm kev tshawb fawb tsis tu ncua, kev npaj ntawm titanium thiab titanium alloy cov khoom siv thev naus laus zis yuav ua kom yooj yim dua thiab cov nqi ua haujlwm yuav qis dua thiab qis dua, thiab cov khoom ntxim nyiam ntawm titanium thiab titanium alloy cov khoom yuav raug nthuav tawm hauv ntau thaj chaw.

Using extrusion txoj kev tuag forging, muaj ob hom forging, Forward Extrusion thiab thim rov qab Extrusion. Extrusion Tuag Forging tuaj yeem tsim ntau yam hollow thiab khoom seem, thiab tuaj yeem tau txais forgings nrog siab geometrical precision thiab denser nrog cov qauv.

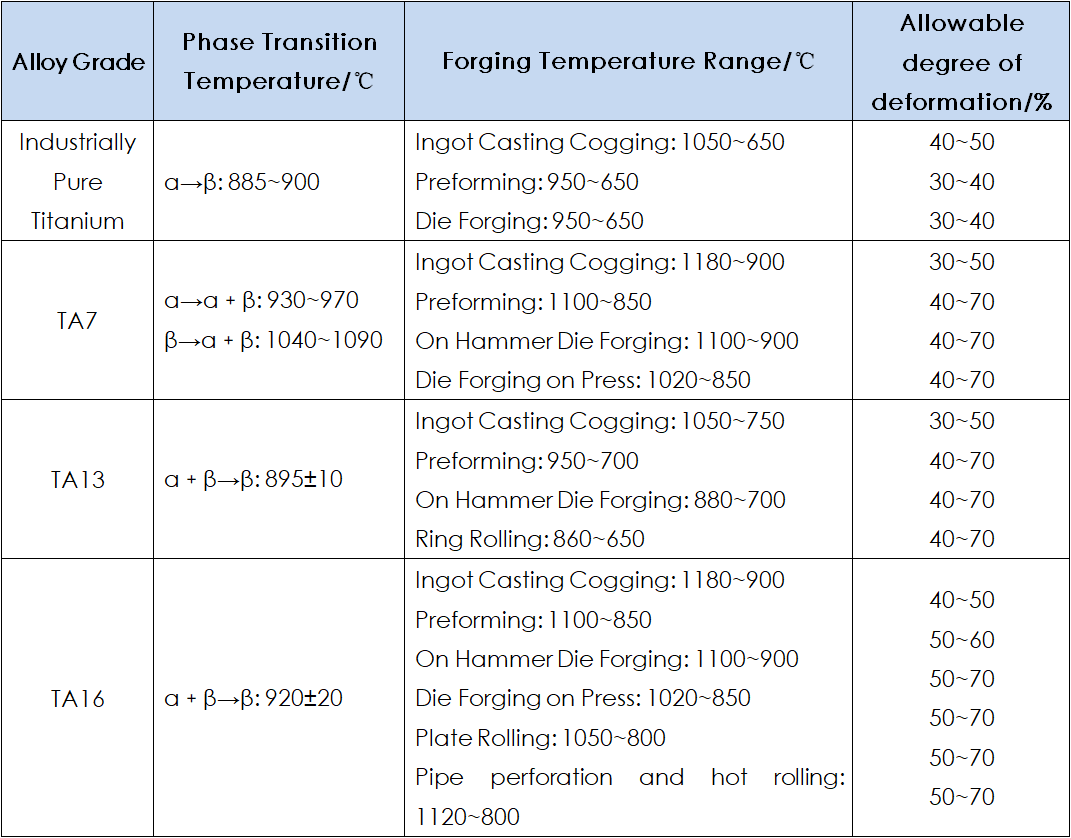

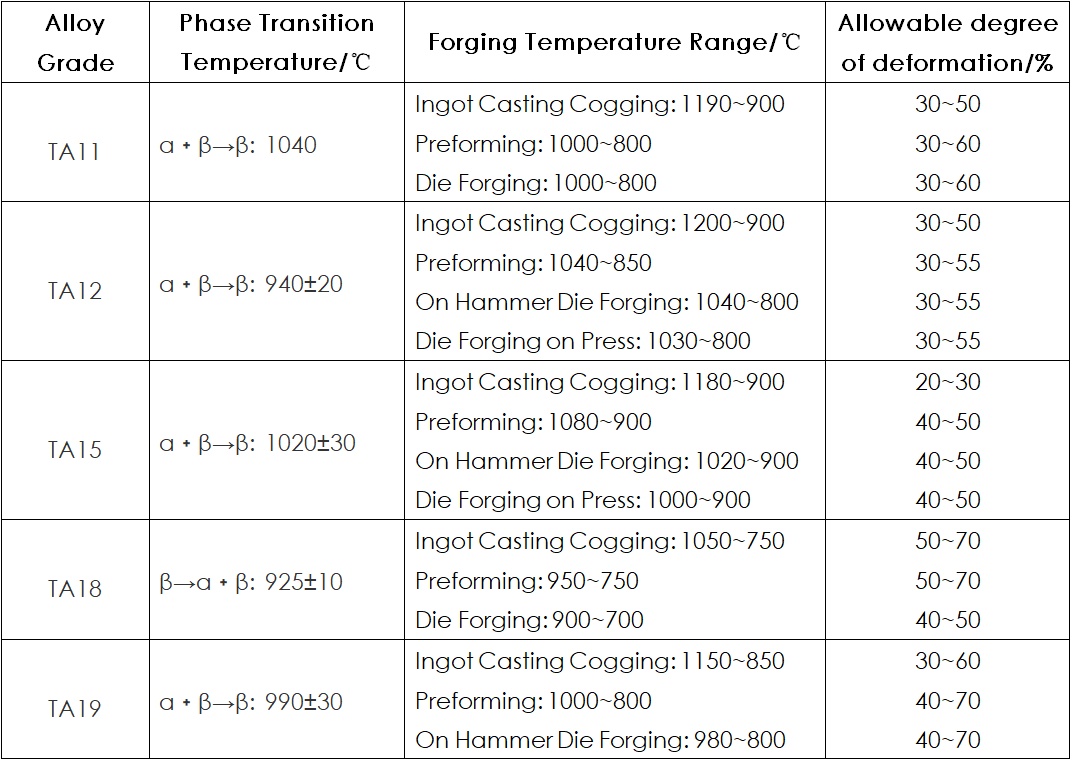

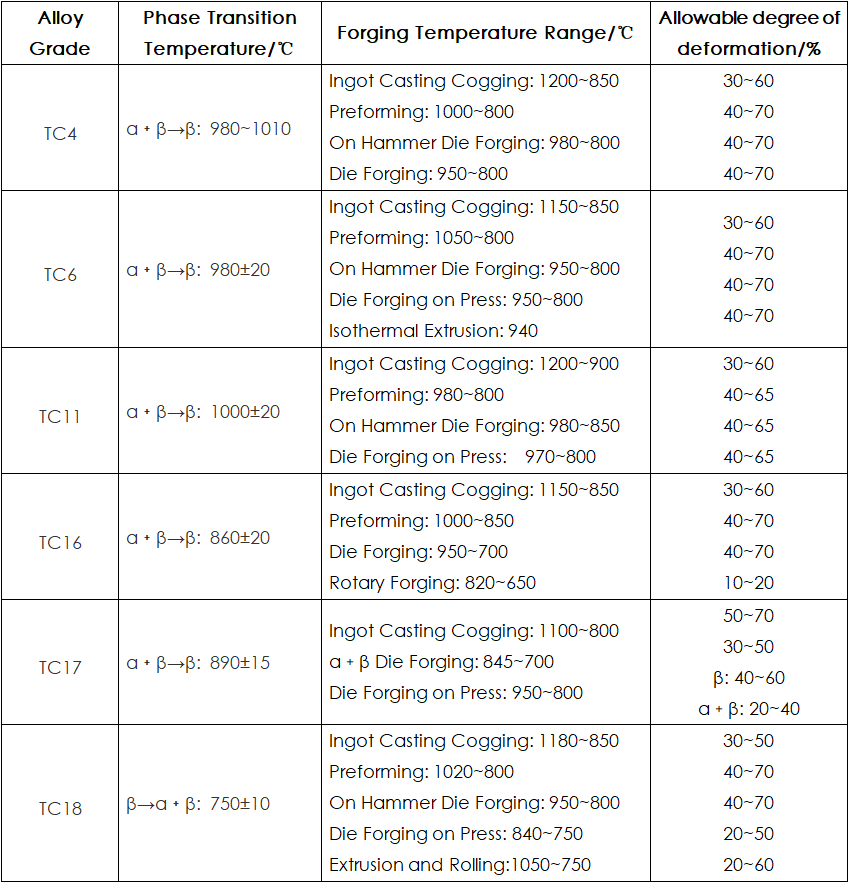

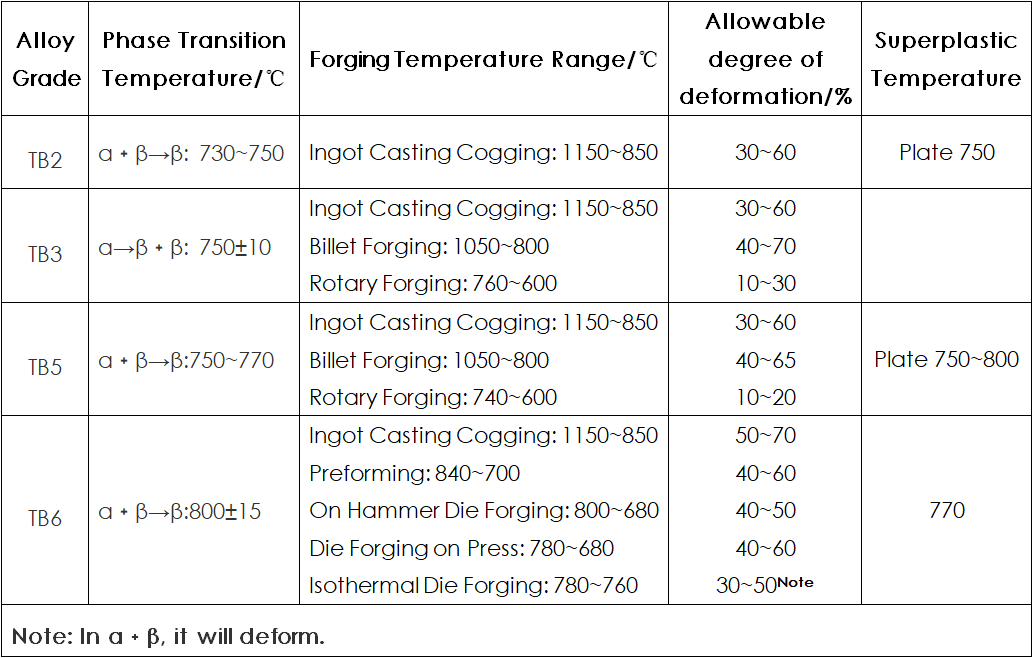

Raws li kev tshawb fawb theoretical thiab kev tsim lub Hoobkas, cov txheej txheem kev ua haujlwm ntawm cov ntaub ntawv ntawm α-type, ze-α-type, α﹢β-hom thiab ze-β-type titanium alloys tau sau tseg hauv Table 1 txog Table 4, feem.

Los ntawm cov ntaub ntawv hauv Table 1 txog Table 4, nws tuaj yeem pom tias qhov ntsuas kub ntawm feem ntau ntawm titanium alloy ingots yog nyob rau hauv thaj tsam ntawm 1150 ° C txog 1200 ° C, thiab qhov pib forging kub ntawm qee qhov titanium alloy ingots yog nyob rau hauv ntau yam. ntawm 1050 ° C txog 1100 ° C; Ob qhov chaw kub no yog ob qho tib si nyob rau hauv cheeb tsam β theem, thiab yav dhau los yog siab tshaj qhov kub hloov pauv rau ntau yam.

Ua ntej, cov alloy muaj siab shaping thiab tsawg deformation kuj nyob rau hauv lub β theem cheeb tsam. Nyob rau hauv thiaj li yuav siv sij hawm ntev forging, Nws yog qhov zoo los txhim kho cov khoom tsim tau; Secondly, lub billet rau ingot blooming yog tsuas yog muab raws li ib tug dawb paug rau forging. Tom qab forging nrog ib tug loj degree ntawm deformation, tus qauv tuaj yeem txhim kho yam tsis muaj kev cuam tshuam rau kev ua haujlwm ntawm forging. Yog li ntawd, ib tug txheej txheem nrog high productivity yog xaiv.

Los ntawm cov ntaub ntawv hauv Table 1 txog Table 4, nws tuaj yeem pom tau tias qhov pib forging kub ntawm tuag forging ntawm cov xovxwm tsis tsuas yog qis dua qhov pib forging kub ntawm ingot billet, tab sis kuj qis dua α / β theem hloov pauv kub. los ntawm 30 ℃ ~ 50 ℃. Feem ntau cov titanium Tuag forging kub ntawm cov hlau yog nyob rau hauv thaj tsam ntawm 930 ℃ ~ 970 ℃, uas yog los xyuas kom meej lub deformation nyob rau hauv lub α﹢β theem cheeb tsam kom tau qhov yuav tsum tau microstructure thiab cov khoom ntawm forging. Txij li thaum forging rauj tuag forging yuav tsum tau ntau lub tshuab thiab lub sijhawm ua haujlwm ntev, qhov tuag forging cua sov ntawm nws cov forgings tiav tuaj yeem tsim nyog nce los ntawm 10 ℃ ~ 20 ℃ dua li ntawm xovxwm forging. Txawm li cas los xij, txhawm rau kom ntseeg tau tias cov qauv thiab cov khoom siv ntawm titanium alloy tiav forgings, Yog li ntawd, qhov kawg forging kub ntawm cov txheej txheem forging yuav tsum tau tswj nyob rau hauv α﹢β ob-theem cheeb tsam.

Nws tseem tuaj yeem pom los ntawm cov ntaub ntawv hauv Table 1 txog Table 4 tias qhov pib forging kub ntawm feem ntau titanium alloy preforms yog me ntsis siab dua los yog ze rau theem hloov pauv kub. Thawj α / β forging kub ntawm txoj kev hloov pauv xws li preforming yog qis dua qhov kub ntawm qhov kub thiab txias, thiab siab dua qhov kub ntawm qhov pib forging ntawm tuag forging. Deformation nyob rau hauv qhov kub thiab txias cheeb tsam tsis tsuas yog saib xyuas cov khoom tsim, tab sis kuj npaj ib tug zoo qauv rau forging.

Table 1 Forging txheej txheem kev ua tau zoo cov ntaub ntawv ntawm α-type titanium

Table 2 Forging txheej txheem kev ua tau zoo cov ntaub ntawv ntawm ze α-hom titanium alloy

Table 3 Forging txheej txheem kev ua tau zoo cov ntaub ntawv ntawm α﹢β titanium alloy

Table 4 Forging txheej txheem kev ua tau zoo cov ntaub ntawv ntawm ze β-hom titanium alloy

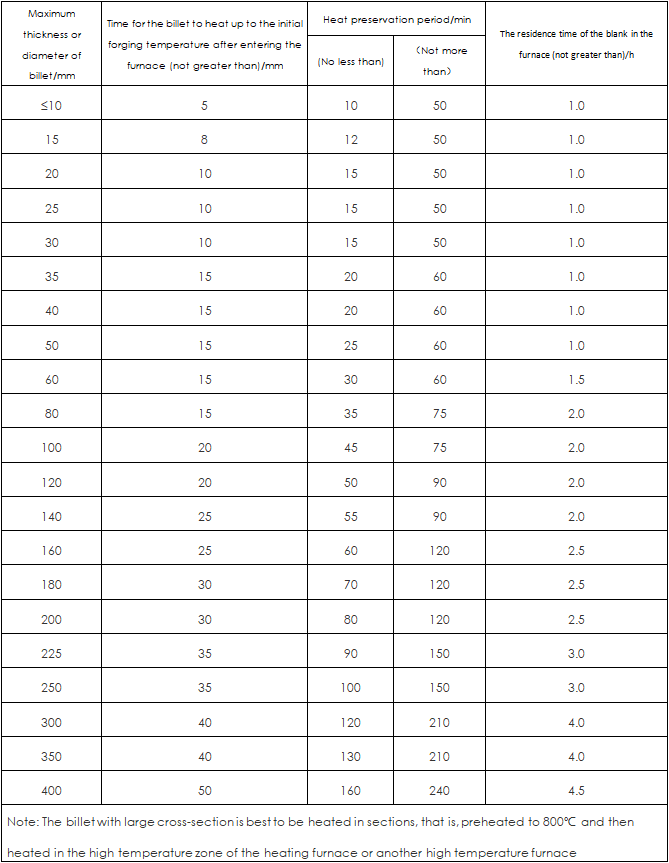

Table 5 Cua sov thiab tuav lub sij hawm ntawm titanium alloy blanks

BMT yog tshwj xeeb hauv kev tsim cov hwm titanium forging thiab titanium alloy forging featuring zoo heev txhua yam muaj peev xwm, tenacity, corrosion kuj, tsawg ceev thiab siab siv. BMT titanium cov khoom 'tus qauv productiono thiab cov txheej txheem tshawb nrhiav tau kov yeej ob qho tib si thev naus laus zis thiab kev ua haujlwm nyuaj ntawm titanium forging manufacturing.

Lub siab zoo precision titanium forging ntau lawm yog raws li cov txheej txheem kev tsim thiab maj mam nce txoj kev. BMT titanium forging tuaj yeem siv rau ntau yam los ntawm cov pob txha me me rau cov qauv loj loj titanium forging rau cov dav hlau.

BMT titanium forgings yog dav siv nyob rau hauv ntau industries, xws li aerospace, offshore engineering, roj thiab roj, kev ua si, khoom noj khoom haus, tsheb, thiab lwm yam. Peb txhua xyoo muaj peev xwm muaj txog li 10,000 tons.

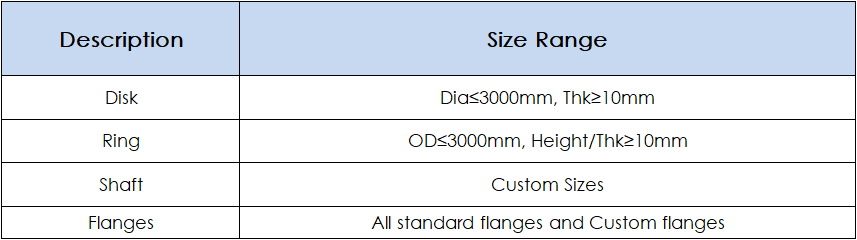

Qhov ntau thiab tsawg:

Muaj cov khoom siv tshuaj lom neeg muaj pes tsawg leeg

Muaj cov khoom siv tshuaj lom neeg muaj pes tsawg leeg

Kev tshuaj ntsuam xyuas:

- Chemical Composition Analysis

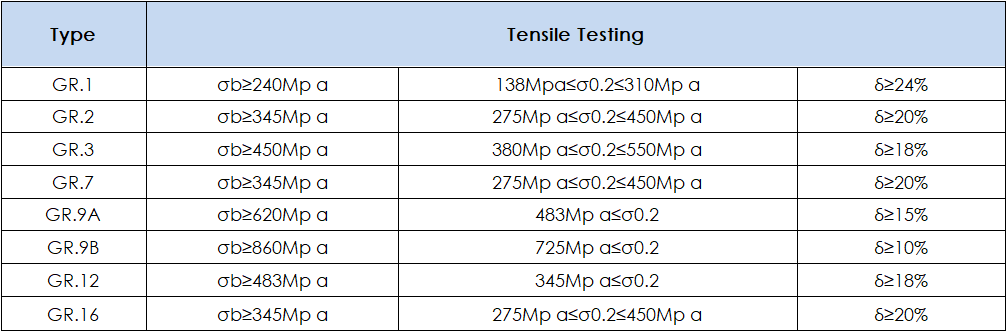

- Mechanical Property Test

- Kev Ntsuas Tensile

- Flaring Test

- Flattening Test

- Bending Test

- Hydro-Static Test

- Pneumatic Test (Kev ntsuas huab cua hauv qab dej)

- NDT Test

- Eddy-Tam sim no Test

- Ultrasonic Test

- LDP Test

- Ferroxyl Test

Productivity (Max thiab Min npaum li cas ntawm Order):Unlimited, raws li kev txiav txim.

Lub Sijhawm Lead:Lub sijhawm ua haujlwm dav dav yog 30 hnub. Txawm li cas los xij, nws nyob ntawm tus nqi ntawm qhov kev txiav txim accringly.

Kev thauj mus los:Txoj kev dav dav ntawm kev thauj mus los yog Hiav Txwv, los ntawm Cua, los ntawm Express, los ntawm Tsheb ciav hlau, uas yuav tsum tau xaiv los ntawm cov neeg siv khoom.

Ntim:

- Cov yeeb nkab kawg yuav tsum tau tiv thaiv nrog lub kaus mom yas lossis cardboard.

- Tag nrho cov fittings yuav tsum tau ntim los tiv thaiv qhov xaus thiab tig ntsej muag.

- Tag nrho lwm cov khoom yuav raug ntim los ntawm cov ntaub qhwv ntsej muag thiab cov hnab yas thiab cov ntaub ntawv plywood.

- Txhua yam ntoo siv rau ntim yuav tsum tsim nyog los tiv thaiv kev sib kis los ntawm kev sib cuag nrog cov cuab yeej tuav.