Peb sim ua kom zoo, tuam txhab cov neeg siv khoom ", vam tias yuav yog qhov zoo tshaj plaws kev koom tes ua haujlwm thiab tus thawj tswj hwm kev lag luam rau cov neeg ua haujlwm, cov chaw muag khoom thiab cov neeg siv khoom, paub txog tus nqi sib koom thiab kev lag luam ruaj khov rau Tuam Tshoj Custom CNC Service Precision Machining CNC Parts Titanium / Steel /Carbon Steel CNC Part, Cov khoom tau txais ntawv pov thawj siv cov thawj coj hauv cheeb tsam thiab thoob ntiaj teb. Rau cov ntaub ntawv ntxaws ntxaws ntxiv, koj yuav tsum tau tuav peb!

Peb sim ua kom zoo tshaj plaws, tuam txhab cov neeg siv khoom ", vam tias yuav yog qhov zoo tshaj plaws kev koom tes ua haujlwm thiab tus thawj tswj hwm kev lag luam rau cov neeg ua haujlwm, cov neeg muag khoom thiab cov neeg siv khoom, paub txog tus nqi sib koom thiab kev lag luam ruaj khov rauCarbon Steel CNC Part, Tuam Tshoj CNC Service Precision, tam sim no peb muaj cov khoom ua tiav cov kab ntau lawm, cov kab sib dhos, kev tswj xyuas qhov zoo, thiab qhov tseem ceeb tshaj plaws, peb tam sim no muaj ntau cov cuab yeej siv technology thiab kev paub txog kev tsim khoom & pab pawg neeg muag khoom, pab pawg neeg muag khoom. Nrog rau tag nrho cov neeg zoo, peb tab tom yuav tsim "lub koob npe nrov thoob ntiaj teb hom nylon monofilaments", thiab nthuav peb cov khoom thiab cov kev daws teeb meem rau txhua lub ces kaum ntawm lub ntiaj teb. Peb txuas ntxiv mus thiab sim peb qhov zoo tshaj plaws los pab peb cov neeg siv khoom.

Titanium Phaj, Sheet thiab Coil

Titanium phaj Manufacturing txheej txheem

Kub Forging Ib txheej txheem forging uas hlau yog recrystallized saum qhov kub thiab txias. Kub dov Cov txheej txheem ntawm dov ntawm qhov kub siab tshaj recrystallization. Txias dov txheej txheem nyob rau hauv uas cov yas deformation kub yog qis dua qhov kub thiab txias.

Annealing: Cov txheej txheem uas cov hlau tau rhuab maj mam mus rau qhov kub thiab txias, rau lub sijhawm txaus, thiab tom qab ntawd txias (feem ntau maj mam thiab qee zaum tswj tau) ntawm tus nqi tsim nyog.

Pickling: Raus cov khoom nyob rau hauv ib tug aqueous tov, xws li sulfuric acid, kom tshem tawm oxides thiab lwm yam nyias zaj duab xis ntawm cov hlau nto.Is electroplating, enamel, dov thiab lwm yam txheej txheem ntawm pre-kev kho mob los yog nruab nrab kev kho mob.

Cov yam ntxwv ntawm titanium phaj

1. Titanium noob phaj yog oxidized zaj duab xis rau ntawm qhov chaw, uas yog sib npaug rau cov plaub hau sib cais tus neeg sawv cev zoo hnav. Kev siv cov titanium noob phaj txuag tus neeg sawv cev sib cais, ua rau lub phaj yooj yim rau tev tawm, tshem tawm cov txheej txheem ntawm preprocessing ntawm cov noob phaj, thiab titanium noob phaj yog ib nrab sib zog dua cov noob tooj liab phaj.

2. Lub neej kev pab cuam ntawm titanium noob phaj yog ntau tshaj 3 npaug ntawm cov phaj tooj liab, uas tuaj yeem ncav cuag 10 mus rau 20 xyoo raws li kev ua haujlwm.

3. Electrolytic tooj liab ua los ntawm titanium noob phaj muaj cov qauv siv lead ua, du nto thiab zoo heev.

4. Vim tias titanium phaj tsis tas yuav tsum tau coated nrog kev sib cais tus neeg sawv cev, nws tuaj yeem zam cov pa phem ntawm tooj liab electrolyte.

5. Txhim kho lub peev xwm ntau lawm thiab txo cov nqi tsim khoom ntawm electrolytic tooj liab, thiaj li ua tiav cov txiaj ntsig kev lag luam zoo dua.

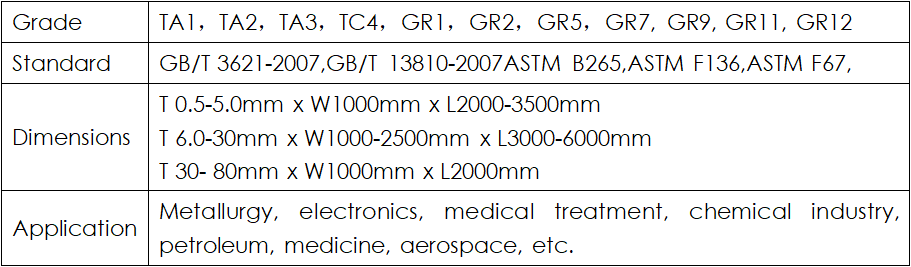

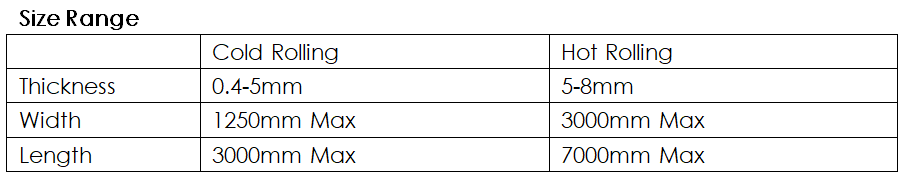

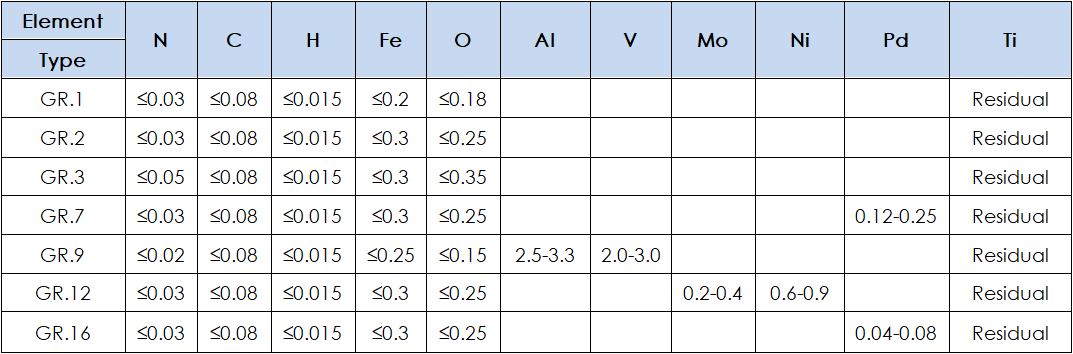

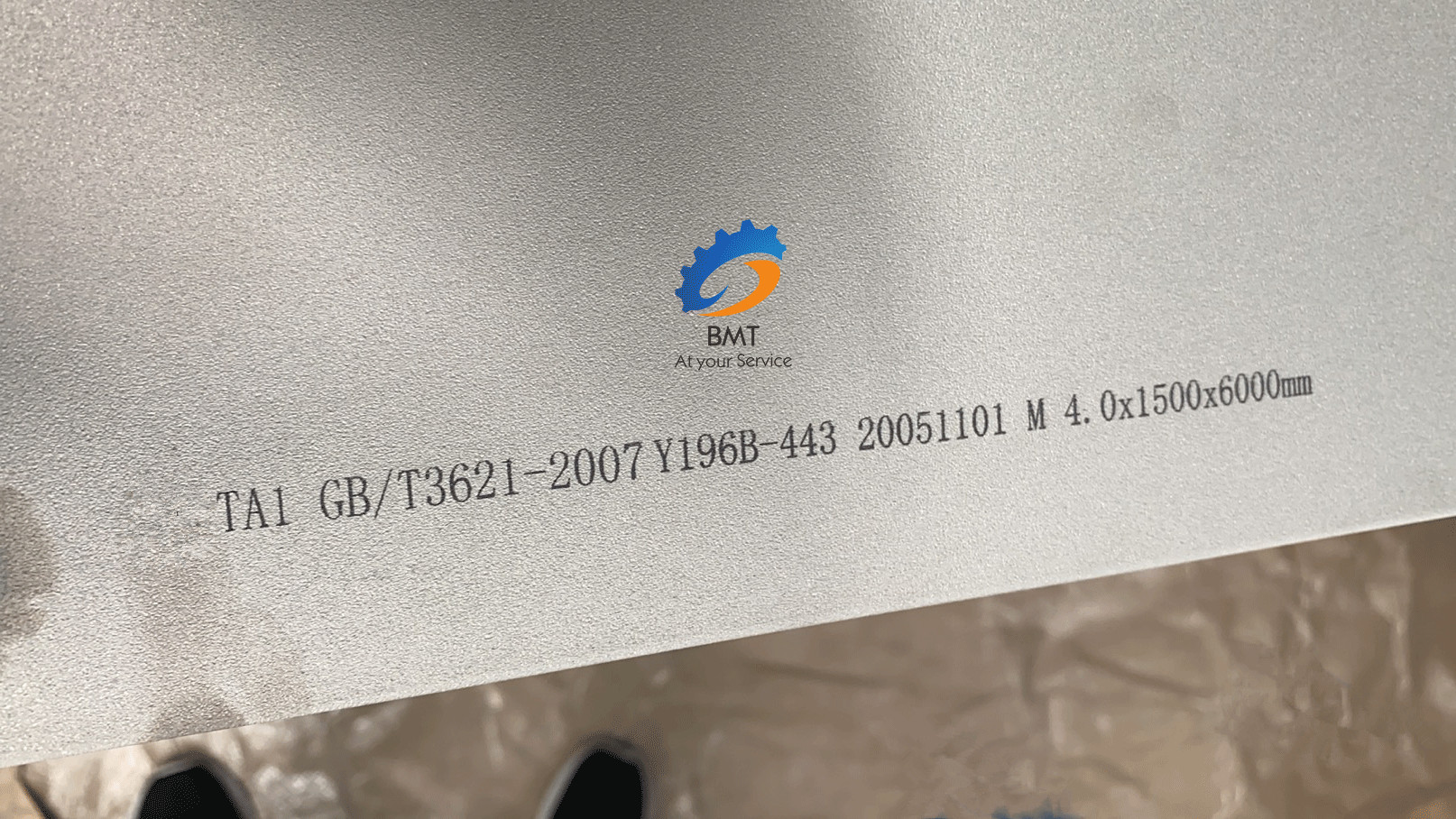

BMT ntau yam ntawm titanium ntawv thiab phaj feem ntau yog ua raws li cov qauv xws li ASTM / ASME B / SB265, ASTM F136, ASTM F67, AMS 4911, thiab AMS4900.

BMT qhov kev tsim txhua xyoo ntawm titanium nplooj ntawv thiab paltes yog 10000 tons, suav nrog 2000 tons rau PHE (Plate for heat exchanger), thiab 8000 tons rau lwm yam kev siv. BMT cov ntaub ntawv zoo titanium thiab daim hlau, nrog rau cov ntawv txias titanium thiab cov ntawv kub dov titanium, yog nyob rau hauv kev soj ntsuam nruj thiab xyuas cov khoom raw-titanium daim txhuam cev. BMT tswj tag nrho cov txheej txheem, xws li melting, forging, kub dov, txias dov, kho cua sov, thiab lwm yam Peb export cov khoom nyob ib ncig ntawm lub ntiaj teb no thiab warmly txais tos koj los koom tes nrog peb.

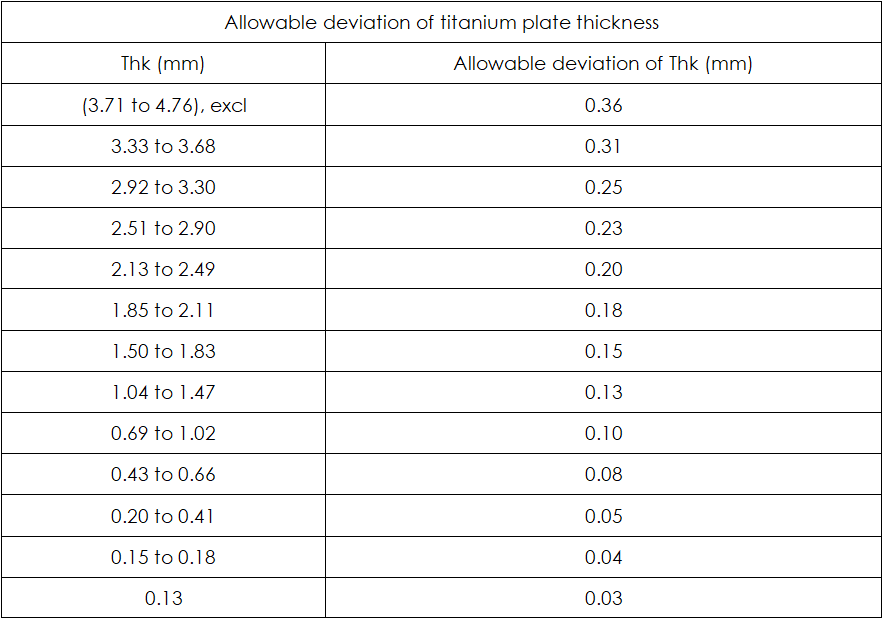

Titanium phaj Thickness tso cai sib txawv:

Muaj Cov Khoom Siv Tshuaj Muaj Zog:

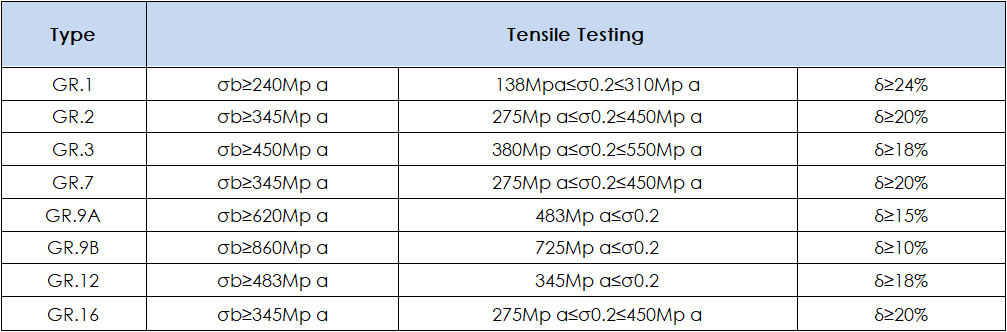

Muaj Khoom Siv Mechanical Property:

Kev tshuaj ntsuam xyuas:

- Chemical Composition Analysis

- Mechanical Property Test

- Kev Ntsuas Tensile

- Flaring Test

- Flattening Test

- Bending Test

- Hydro-Static Test

- Pneumatic Test (Kev ntsuas huab cua hauv qab dej)

- NDT Test

- Eddy-Tam sim no Test

- Ultrasonic Test

- LDP Test

- Ferroxyl Test

Productivity (Max thiab Min npaum li cas ntawm Order):Unlimited, raws li kev txiav txim.

Lub Sijhawm Lead:Lub sijhawm ua haujlwm dav dav yog 30 hnub. Txawm li cas los xij, nws nyob ntawm tus nqi ntawm qhov kev txiav txim accringly.

Kev thauj mus los:Txoj kev dav dav ntawm kev thauj mus los yog Hiav Txwv, los ntawm Cua, los ntawm Express, los ntawm Tsheb ciav hlau, uas yuav tsum tau xaiv los ntawm cov neeg siv khoom.

Ntim:

- Cov yeeb nkab kawg yuav tsum tau tiv thaiv nrog lub kaus mom yas lossis cardboard.

- Tag nrho cov fittings yuav tsum tau ntim los tiv thaiv qhov xaus thiab tig ntsej muag.

- Tag nrho lwm cov khoom yuav raug ntim los ntawm cov ntaub qhwv ntsej muag thiab cov hnab yas thiab cov ntaub ntawv plywood.

- Txhua yam ntoo siv rau ntim yuav tsum tsim nyog los tiv thaiv kev sib kis los ntawm kev sib cuag nrog cov cuab yeej tuav.

Peb sim ua kom zoo tshaj plaws, tuam txhab cov neeg siv khoom ", vam tias yuav yog qhov zoo tshaj plaws kev koom tes ua haujlwm thiab tus thawj tswj hwm kev lag luam rau cov neeg ua haujlwm, cov chaw muag khoom thiab cov neeg siv khoom, paub txog tus nqi sib koom thiab kev lag luam ruaj khov rau Tuam Tshoj Custom CNC Service Precision Machining CNC Parts Titanium / Steel / Carbon Steel CNC Part, Cov Khoom Siv tau txais ntawv pov thawj siv cov thawj coj hauv cheeb tsam thiab thoob ntiaj teb. Rau cov ntaub ntawv ntxaws ntxaws ntxiv, koj yuav tsum tau tuav peb!

Peb sim ua kom zoo tshaj plaws, tuam txhab cov neeg siv khoom ", vam tias yuav yog qhov zoo tshaj plaws kev koom tes ua haujlwm thiab tus thawj tswj hwm kev lag luam rau cov neeg ua haujlwm, cov chaw muag khoom thiab cov neeg siv khoom, paub txog tus nqi sib koom thiab kev lag luam ruaj khov rau Tuam Tshoj Custom CNC Service Precision Machining CNC Parts Titanium / Steel / Carbon Steel CNC Part, Cov Khoom Siv tau txais ntawv pov thawj siv cov thawj coj hauv cheeb tsam thiab thoob ntiaj teb. Rau cov ntaub ntawv ntxaws ntxaws ntxiv, koj yuav tsum tau tuav peb!

Leading Chaw tsim tshuaj paus rauTuam Tshoj CNC Service Precision, Carbon Steel CNC Part, tam sim no peb muaj cov khoom ua tiav cov kab ntau lawm, cov kab sib dhos, kev tswj xyuas qhov zoo, thiab qhov tseem ceeb tshaj plaws, peb tam sim no muaj ntau yam cuab yeej technology thiab kev paub txog kev ua haujlwm & pab pawg tsim khoom, pab pawg kws tshaj lij kev muag khoom. Nrog rau tag nrho cov neeg zoo, peb tab tom yuav tsim "lub koob npe nrov thoob ntiaj teb hom nylon monofilaments", thiab nthuav peb cov khoom thiab cov kev daws teeb meem rau txhua lub ces kaum ntawm lub ntiaj teb. Peb txuas ntxiv mus thiab sim peb qhov zoo tshaj plaws los pab peb cov neeg siv khoom.