Kev sib tsoo

Kev sib tsoo ua tiav yog ua tiav machining (machining yog muab faib ua ntxhib machining, ua tiav machining, kev kho cua sov thiab lwm yam kev ua), nrog rau kev ua haujlwm tsawg thiab siab precision. Nws yog dav siv nyob rau hauv machinery manufacturing kev lag luam. Thaum tshav kub kub kho thiab quenched carbon cuab yeej steel thiab carburized thiab quenched steel qhov chaw feem ntau muaj ib tug loj tus naj npawb ntawm tsis tu ncua txheej txheem kab nrib pleb - sib tsoo cov kab nrib pleb - nyob rau saum npoo uas yog ib txwm perpendicular rau kev sib tsoo kev taw qhia thaum sib tsoo. Nws tsis tsuas yog cuam tshuam cov tsos ntawm cov khoom, tab sis kuj ncaj qha cuam tshuam rau qhov zoo ntawm qhov chaw.

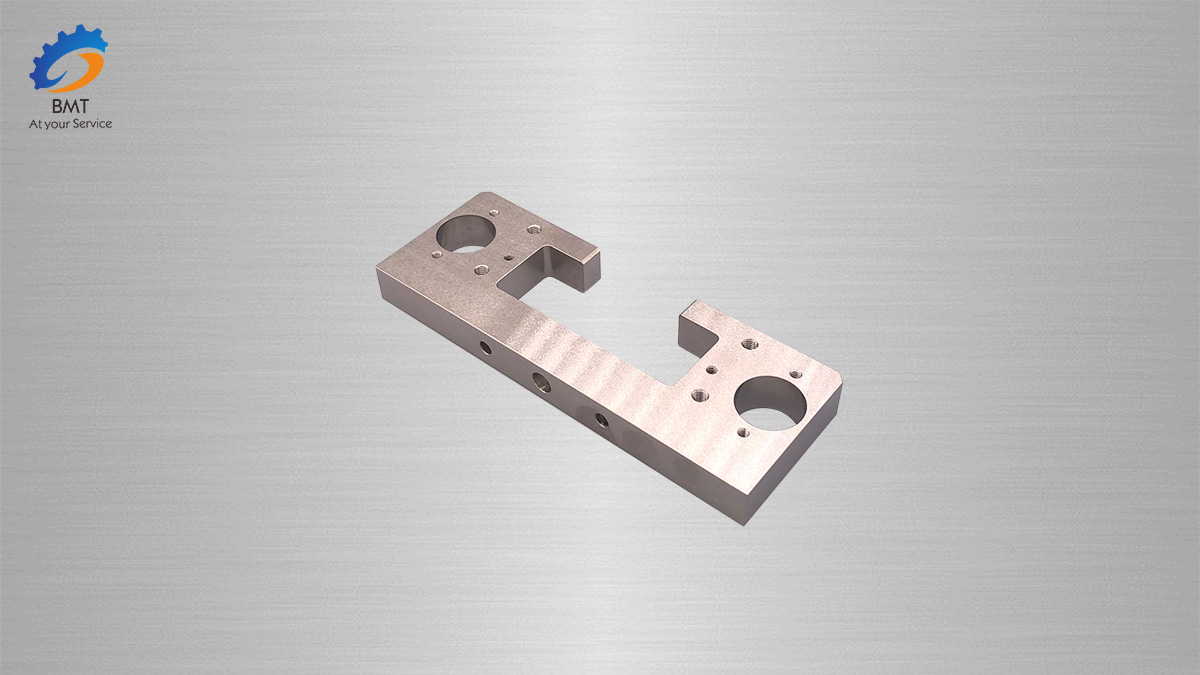

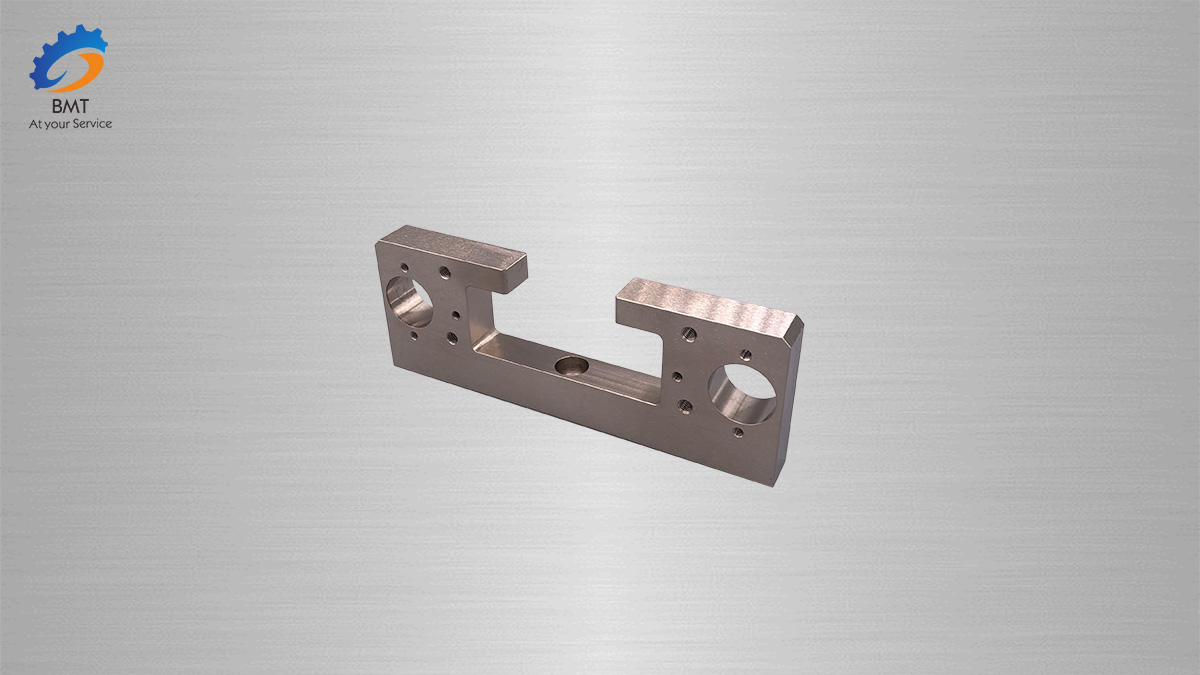

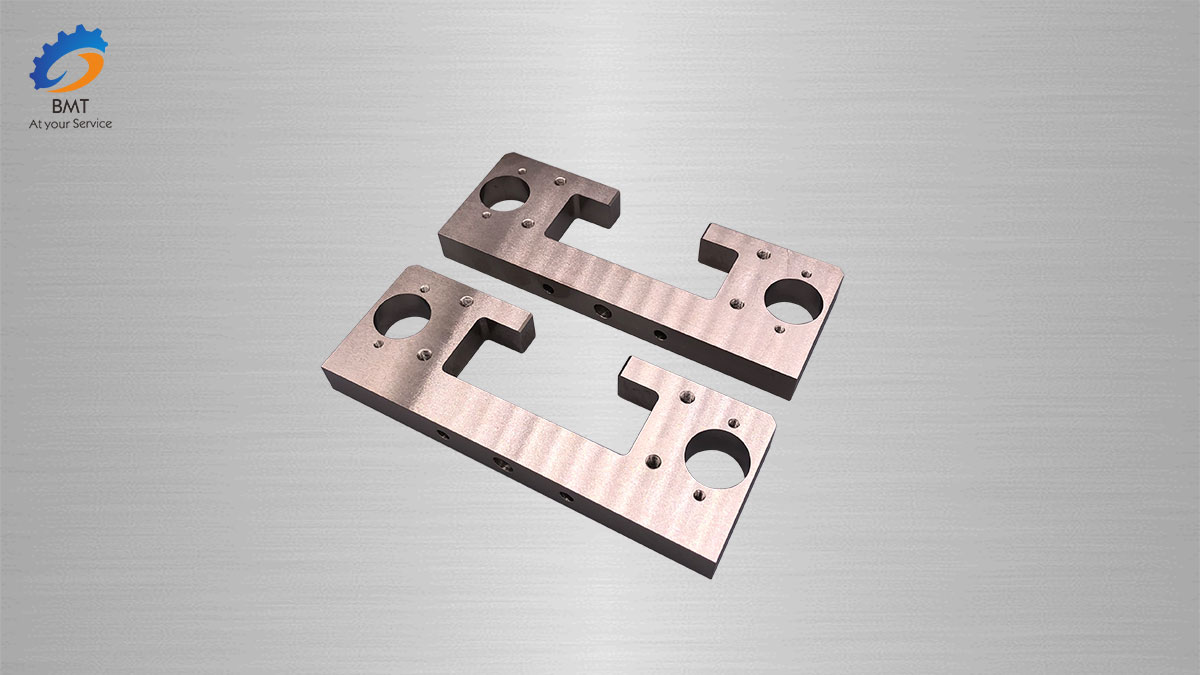

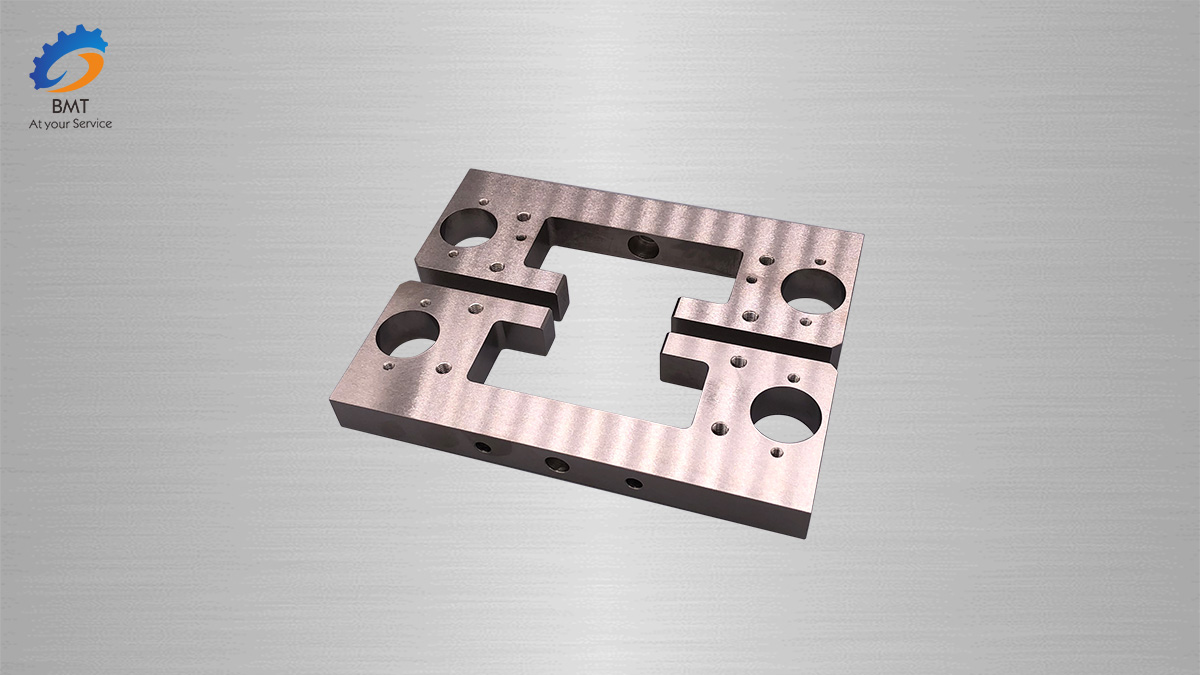

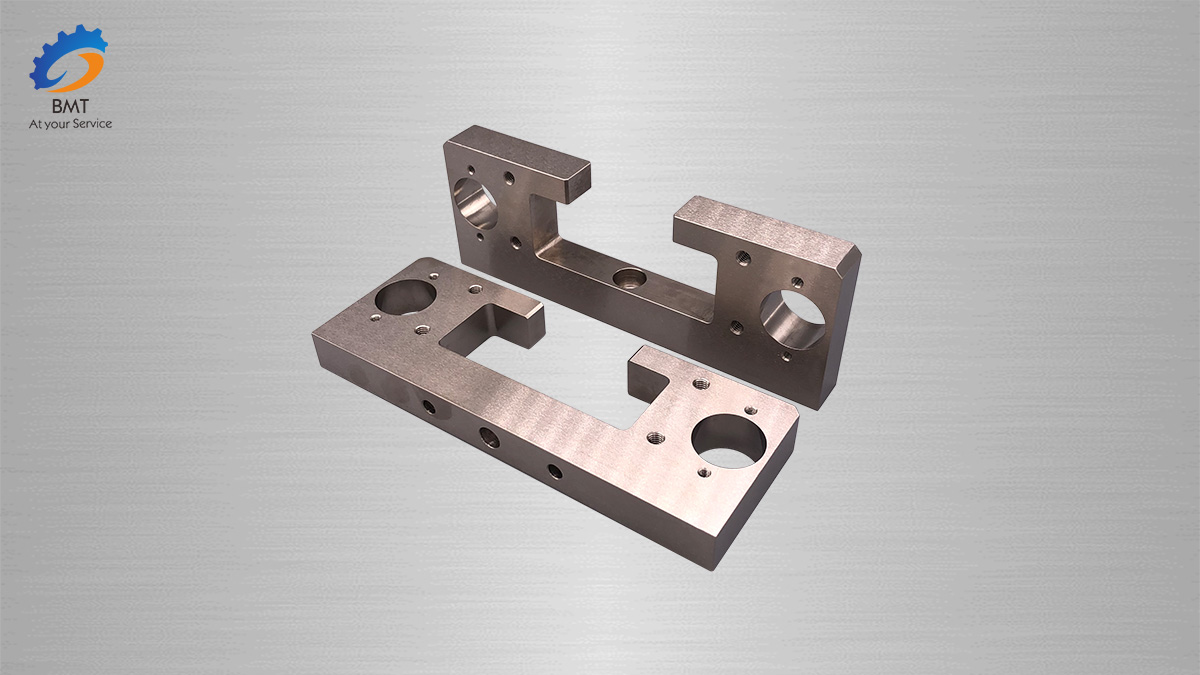

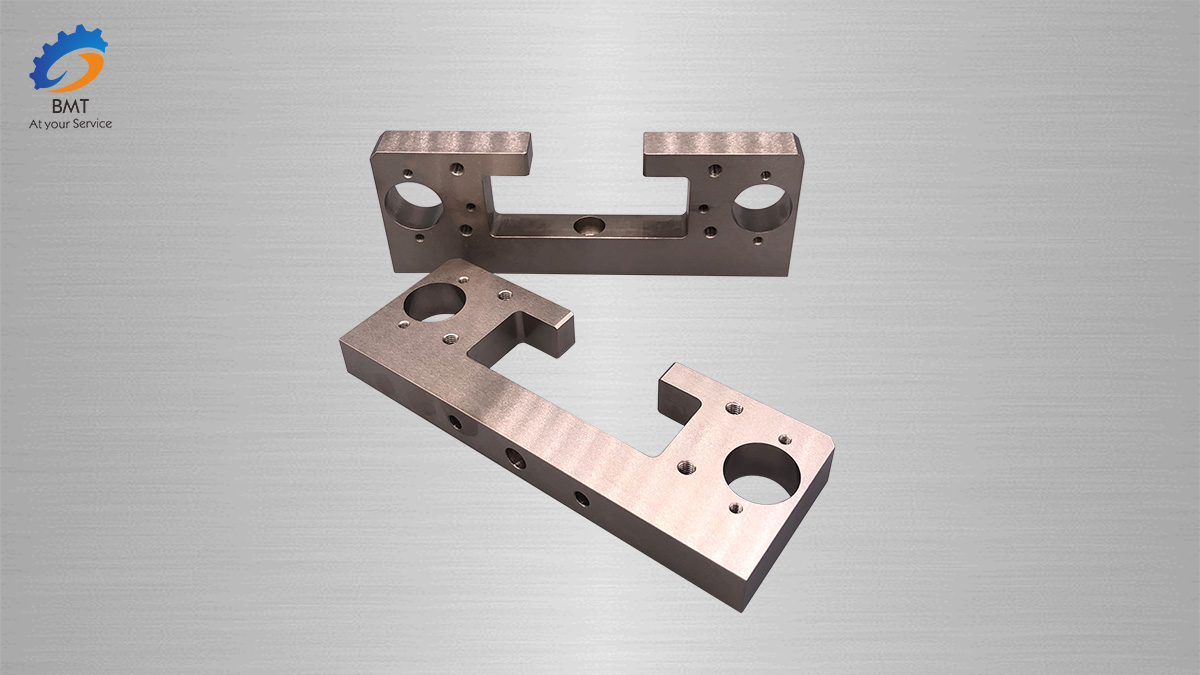

Nws hais txog cov txheej txheem txiav ntawm workpiece nto nrog high-speed rotating sib tsoo log thiab lwm yam cuab yeej abrasive. Kev sib tsoo yog siv los ua cov txheej txheem sab hauv thiab sab nraud cylindrical nto, conical nto thiab dav hlau ntawm ntau yam workpieces, nrog rau tshwj xeeb thiab complex tsim nto xws li Ge Ban chips, threads, zog thiab splines.

Vim lub siab hardness ntawm abrasive grains thiab tus kheej-sharpening ntawm abrasive cov cuab yeej, sib tsoo yuav siv tau los ua ntau yam ntaub ntawv, xws li hardened steel, high-strength alloy steel, nyuaj alloy, iav, ceramics, marble thiab lwm yam siab hardness hlau thiab cov ntaub ntawv uas tsis yog xim hlau. Kev sib tsoo ceev yog hais txog linear ceev ntawm lub log sib tsoo, uas feem ntau yog 30 ~ 35 m / s. Yog hais tias nws siab tshaj 45 m / s, nws yog hu ua high-speed sib tsoo.

Kev sib tsoo feem ntau yog siv rau kev ua tiav thiab ua tiav, thiab qhov tseeb tuaj yeem ncav cuag IT8 ~ 5 lossis siab dua. Qhov saum npoo roughness feem ntau yog av rau Ra1.25 ~ 0.16 μ m, precision sib tsoo rau Ra0.16 ~ 0.04 μ m, ultra precision sib tsoo rau Ra0.04 ~ 0.01 μ m, thiab daim iav sib tsoo rau Ra0.01 μ m. Lub zog tshwj xeeb ntawm kev sib tsoo (los yog kev siv hluav taws xob tshwj xeeb, uas yog, lub zog siv los txiav cov khoom ua haujlwm hauv ib chav tsev ntim) loj dua li ntawm kev txiav dav dav, thiab cov hlau tshem tawm tus nqi tsawg dua li ntawm kev txiav.

Yog li ntawd, ua ntej sib tsoo, lub workpiece feem ntau yog muab tshem tawm los ntawm lwm txoj kev txiav kom tshem tawm cov nyiaj machining ntawm qhov loj ntawm Jiang Ali, tsuas yog 0.1 ~ 1 hli los yog tsawg dua ntawm cov nyiaj sib tsoo. Nrog rau txoj kev loj hlob ntawm high efficiency sib tsoo, xws li creep pub sib tsoo thiab kev kub ceev sib tsoo, qhov chaw tuaj yeem ua hauv av ncaj qha los ntawm qhov khoob. Nws tseem tuaj yeem siv rau kev ua haujlwm ntxhib los ntawm kev sib tsoo, xws li tshem tawm cov khiav thiab riser ntawm castings, flash ntawm forgings thiab daim tawv nqaij ntawm steel ingots.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes