5 Txoj Kev Txhim Kho Cov Ntawv Hlau Qhov Chaw

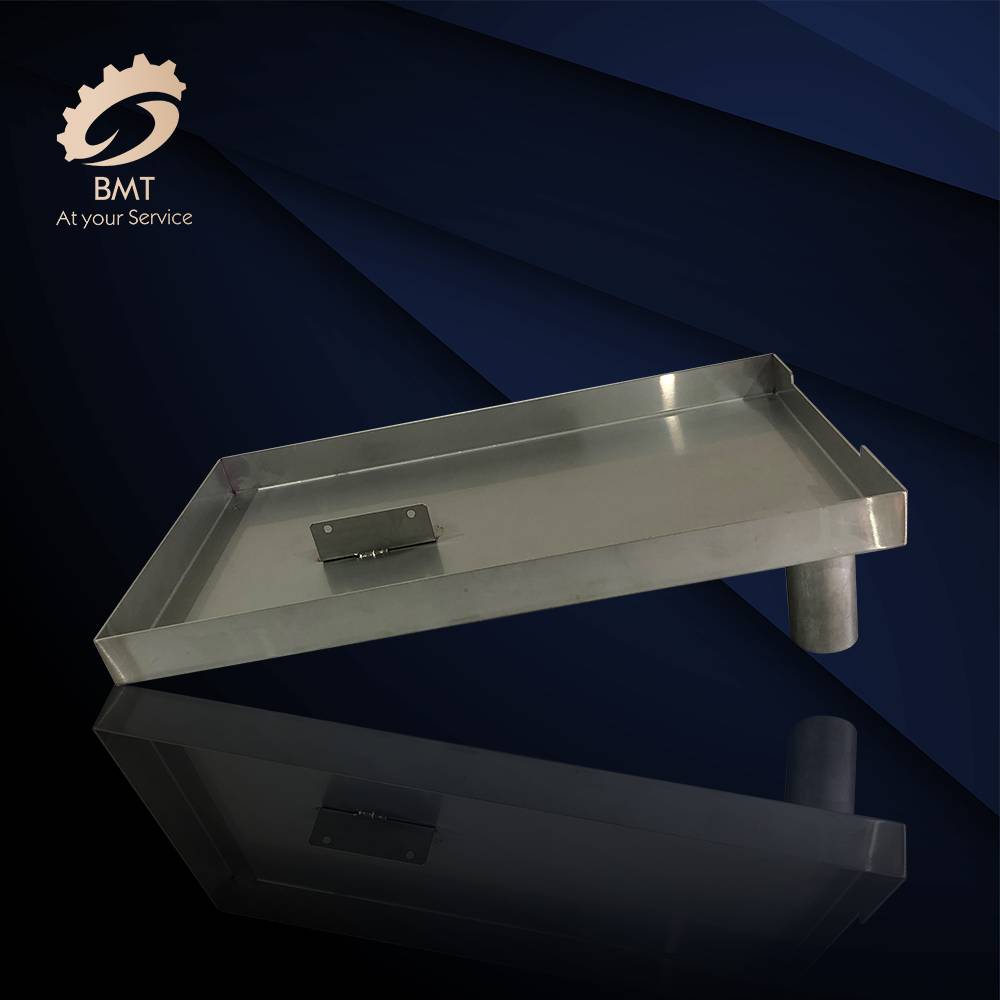

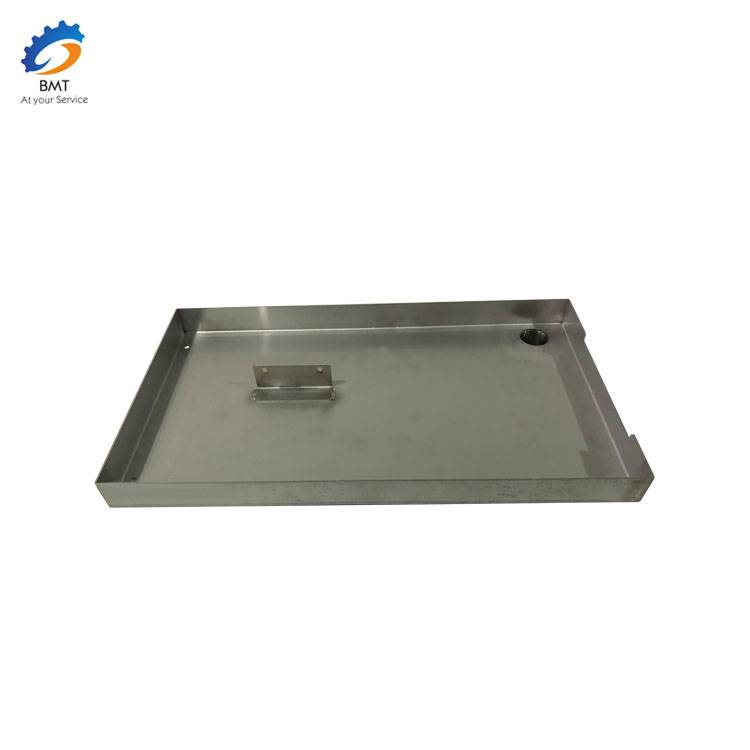

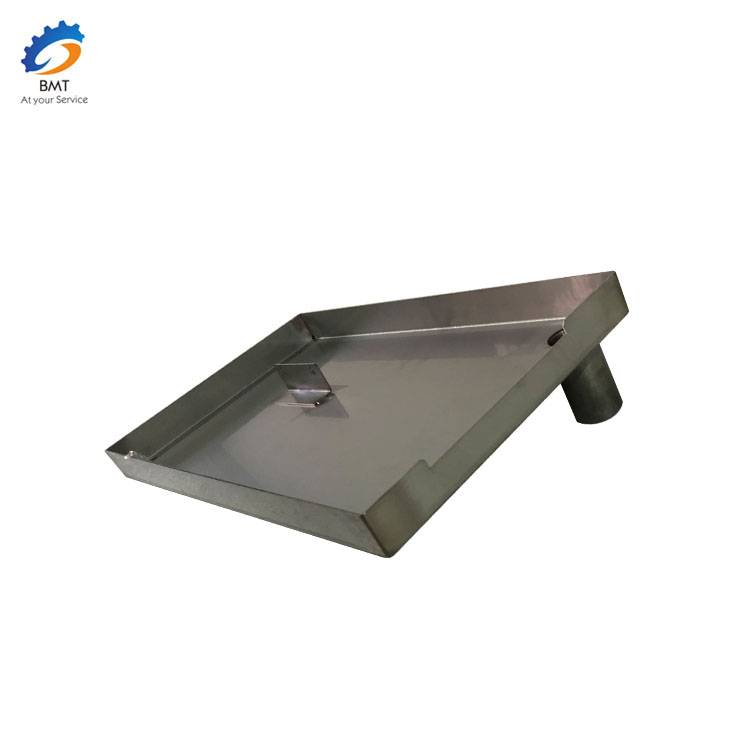

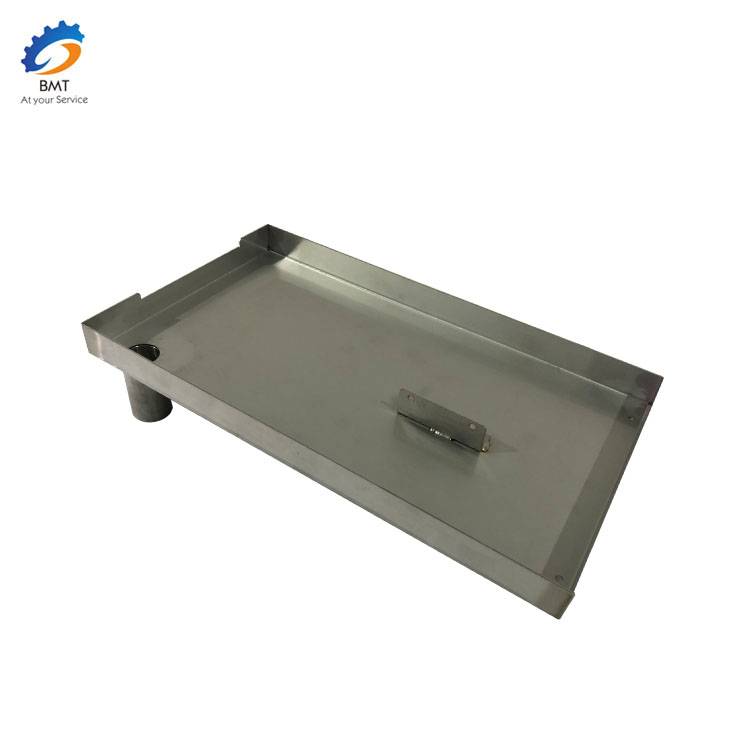

Sheet hlau fabrication yog ib txheej txheej ntawm kev tsim khoom siv los tsim cov khoom los ntawm cov hlau tiaj tus. Sheet hlau los ntawm ntau cov ntaub ntawv thiab thicknesses, thiab tuaj yeem siv los tsim cov khoom xws li cov khoom siv, cov ntaub ntawv, cov hlua khi, cov panels thiab chassis, thiab lwm yam.

Piv nrog rau CNC machining, daim ntawv hlau fabrication yog dictated los ntawm heev nruj tsim specifications. Rau qee tus neeg ua haujlwm tshiab rau kev tsim cov ntawv hlau, tej zaum nws nyuaj. Cov ntawv hlau yuav tsum tau khoov thiab txiav hauv txoj kev tshwj xeeb, thiab tsuas yog haum rau qee yam khoom thiab cov khoom.

Raws li qhov tseeb, nws yog ib qho tseem ceeb uas yuav tsum tau kawm qee cov hauv paus ntsiab lus ntawm kev tsim cov ntawv hlau ua ntej ua haujlwm. Siv cov ntaub ntawv hlau fabrication, cov kws tshaj lij tuaj yeem tsim cov khoom ruaj khov, tus nqi qis los ntawm cov khoom sib txawv. Cov khoom no tuaj yeem siv thoob plaws ntau yam kev lag luam, los ntawm aerospace mus rau cov khoom siv hauv tsev.

Cov ntawv hlau tuab siv hauv cov txheej txheem tsim khoom feem ntau yog nruab nrab ntawm 0.006 thiab 0.25 ", nrog rau qhov ntev ntawm cov khoom siv thiab kev siv kawg ntawm qhov.

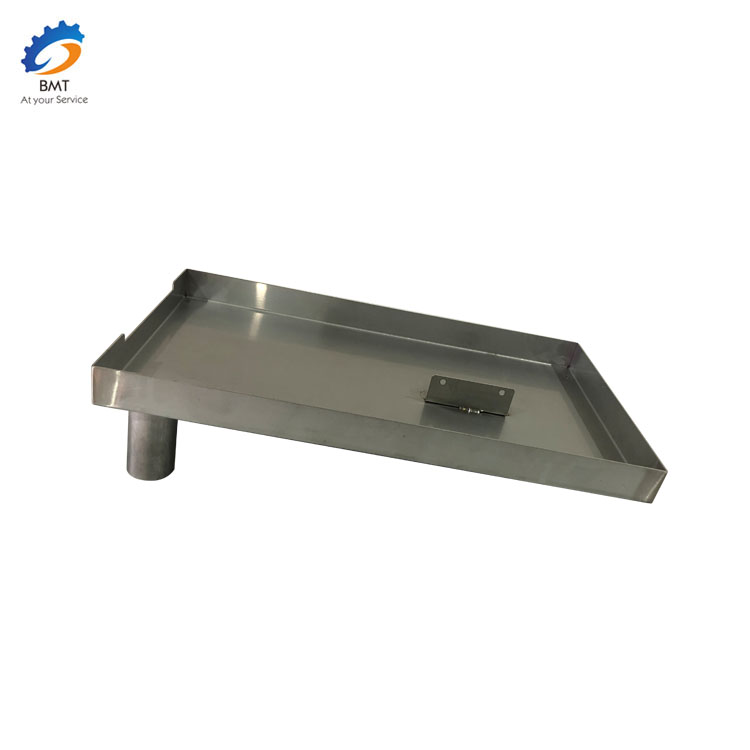

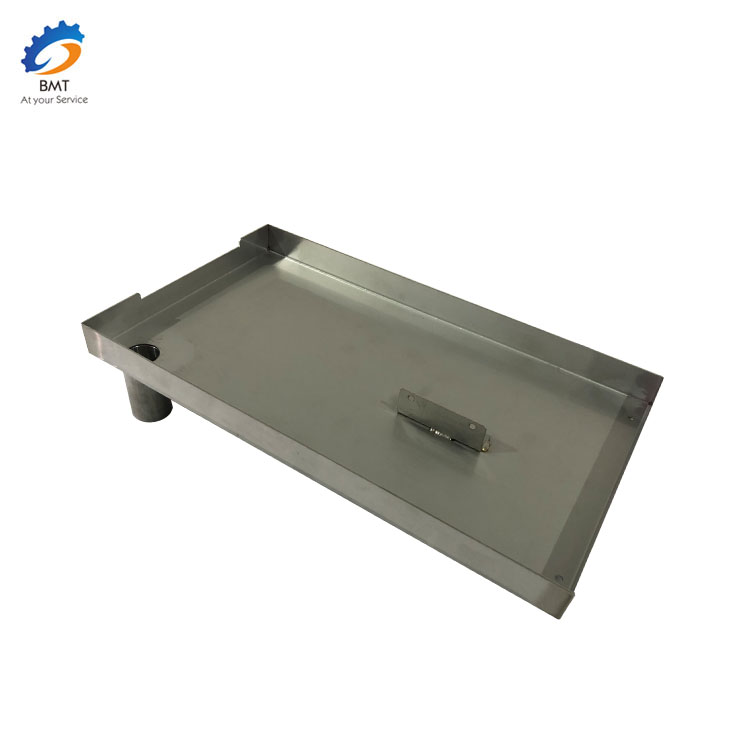

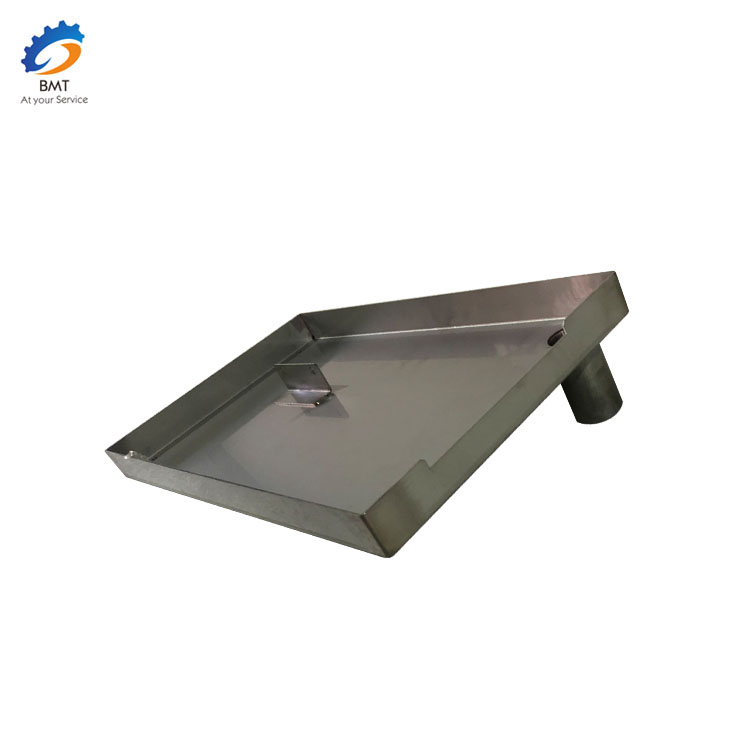

Product Description

Sheet hlau fabrication yog qhov tshwj xeeb ntawm ntau yam kev tsim khoom. Vim li no, cov txheej txheem tej zaum yuav tsim CNC machining qhov chaw lossis pwm qhov chaw, tab sis nws yog ib qho nyuaj rau tsim cov ntawv hlau.

Los ntawm kev soj ntsuam 6 lub tswv yim hauv qab no, cov neeg tsim qauv tuaj yeem tsim cov ntawv hlau uas muaj zog, yooj yim rau fabricate thiab tiv taus ntau dua rau kev tawg.

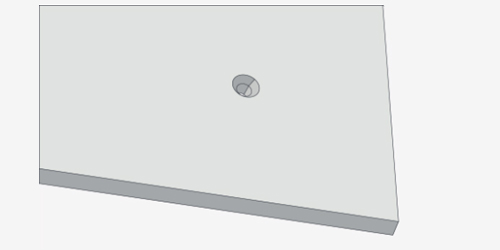

1. Qhov thiab qhov

Txij li cov ntawv hlau fabrication feem ntau siv los tsim cov ntaub thaiv npog, cov hlua khi thiab cov khoom zoo sib xws, qhov thiab cov qhov feem ntau yuav tsum tau siv rau cov ntsia hlau, bolts lossis cov ntu sib txuas. Qhov feem ntau yog tsim nrog lub punch thiab tuag mounted nyob rau hauv ib tug xovxwm, tso cai rau ib tug meej ncig zoo li yuav raug txiav tawm ntawm daim ntawv hlau. Tab sis yog tias qhov tsis raug ua kom raug, lub qhov yuav deform los yog ua rau nws tus kheej tawg.

Thaum xuas nrig ntaus qhov hauv cov ntawv hlau, ob peb txoj cai tseem ceeb yuav tsum ua raws. Qhov yuav tsum yog 1/8 "los ntawm cov phab ntsa lossis ntug thiab yuav tsum tau sib nrug los ntawm tsawg kawg yog 6 npaug ntawm cov ntawv hlau. Tsis tas li ntawd, txoj kab uas hla ntawm tag nrho cov qhov thiab qhov yuav tsum sib phim lossis tshaj qhov tuab ntawm cov ntawv hlau.

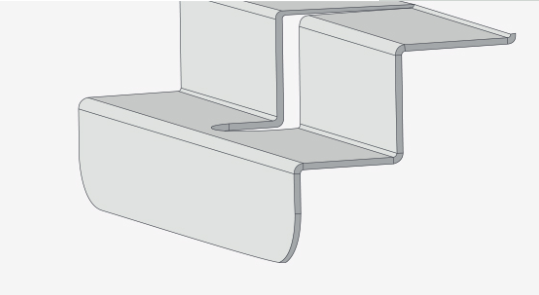

2. Hem

Hemming yog ib txoj hauv kev zoo los ua kom cov ntawv hlau muaj kev nyab xeeb thiab ua haujlwm zoo. Peb tsim ob qho tib si qhib thiab kaw hems. Lub siab ntev ntawm lub hem yog nyob ntawm lub hem lub vojvoog, cov khoom thickness, thiab nta ze ntawm lub hem. Peb pom zoo tias qhov tsawg kawg nkaus hauv txoj kab uas hla sib npaug ntawm cov khoom tuab, thiab lub hem rov qab ntev ntawm 6x cov khoom tuab.

Thaum ntxiv ib lub hem rau ib daim ntawv hlau, ob peb cov lus qhia yuav tsum tau ua raws li kev ua haujlwm zoo. Rau qhov pib, nws yuav luag zoo dua kom tsis txhob kaw hems. Kaw hems yuav ua rau cov khoom puas tsuaj vim yog lub kaum sab xis ntawm qhov khoov, yog li qhib hems, uas tawm ntawm qhov sib txawv ntawm ob sab ntawm lub hem, yog qhov zoo dua.

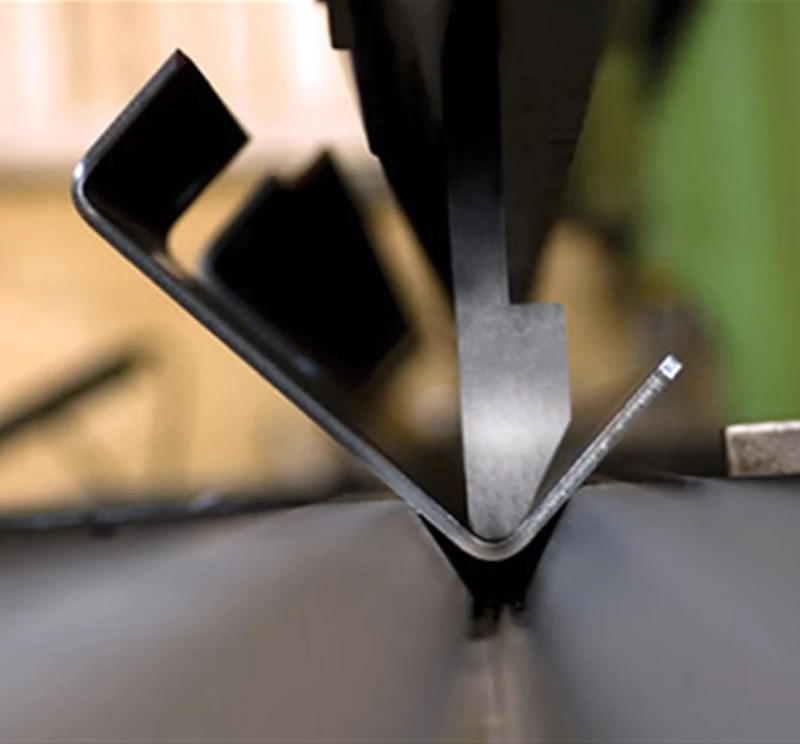

3. Khoov

dabtsi yog khoov yog ib qho tseem ceeb tshaj plaws txheej txheem nyob rau hauv daim ntawv hlau fabrication. Siv cov cuab yeej xws li brakes thiab tshuab presses, lub Hoobkas muaj peev xwm los tswj cov ntawv hlau rau hauv cov duab tshiab. Rau kev khoov, txhawm rau kom ntseeg tau tias qhov tseeb thiab txawm tias khoov, peb yuav tsum ua raws li qee txoj cai, thiab txo qhov muaj peev xwm ntawm kev puas tsuaj rau cov khoom.

Ib txoj cai yuav tsum ua raws li yog tias, thaum tsim ib daim ntawv hlau nrog khoov, sab hauv khoov vojvoog yuav tsum sib phim lossis tshaj qhov tuab ntawm cov ntawv hlau kom tsis txhob deformation. Nws raug nquahu kom siv tib lub vojvoog hla txhua qhov khoov. Kev tswj xyuas qhov sib xws ntawm cov kev taw qhia khoov thiab lub vojvoog tuaj yeem pab txo cov nqi, vim tias qhov yuav tsis tas yuav tsum tau rov ua dua thiab cov khoom siv khoov tuaj yeem rov ua dua ib txoj haujlwm zoo ib yam.

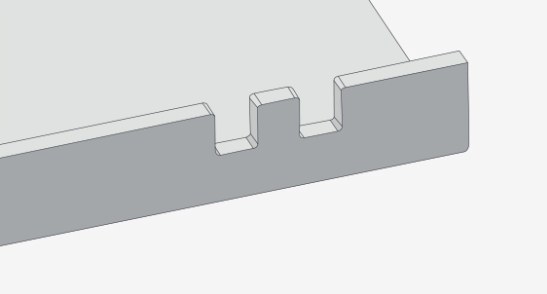

4. Notches thiab Tabs

Notches thiab tabs yog cov yam ntxwv tseem ceeb ntawm cov ntawv hlau qhov chaw uas muaj txiaj ntsig zoo rau kev ntxiv screws lossis fasteners lossis rau slotting ntau qhov chaw ua ke. Notches yog me me indents nyob rau hauv ntug ntawm ib feem, thaum tabs yog protruding nta. Ib lub tab nyob rau hauv ib daim ntawv hlau feem ntau yog sib xyaw kom haum rau hauv ib qho kev txiav ntawm lwm qhov.

Zoo li lwm cov ntawv hlau nta, tsim kom haum cov ntawv thiab cov tabs kuj yuav tsum tau ua raws li qee cov kev cai: cov ntaub ntawv yuav tsum yog yam tsawg kawg nkaus ntawm cov khoom thickness los yog 1 hli, qhov twg yog qhov ntau dua, thiab tsis pub ntev tshaj 5 npaug ntawm nws qhov dav. Tabs yuav tsum muaj tsawg kawg yog 2 npaug ntawm cov khoom thickness los yog 3.2 hli, qhov twg yog qhov ntau dua, thiab tuaj yeem tsis pub ntev tshaj 5 npaug ntawm nws qhov dav.

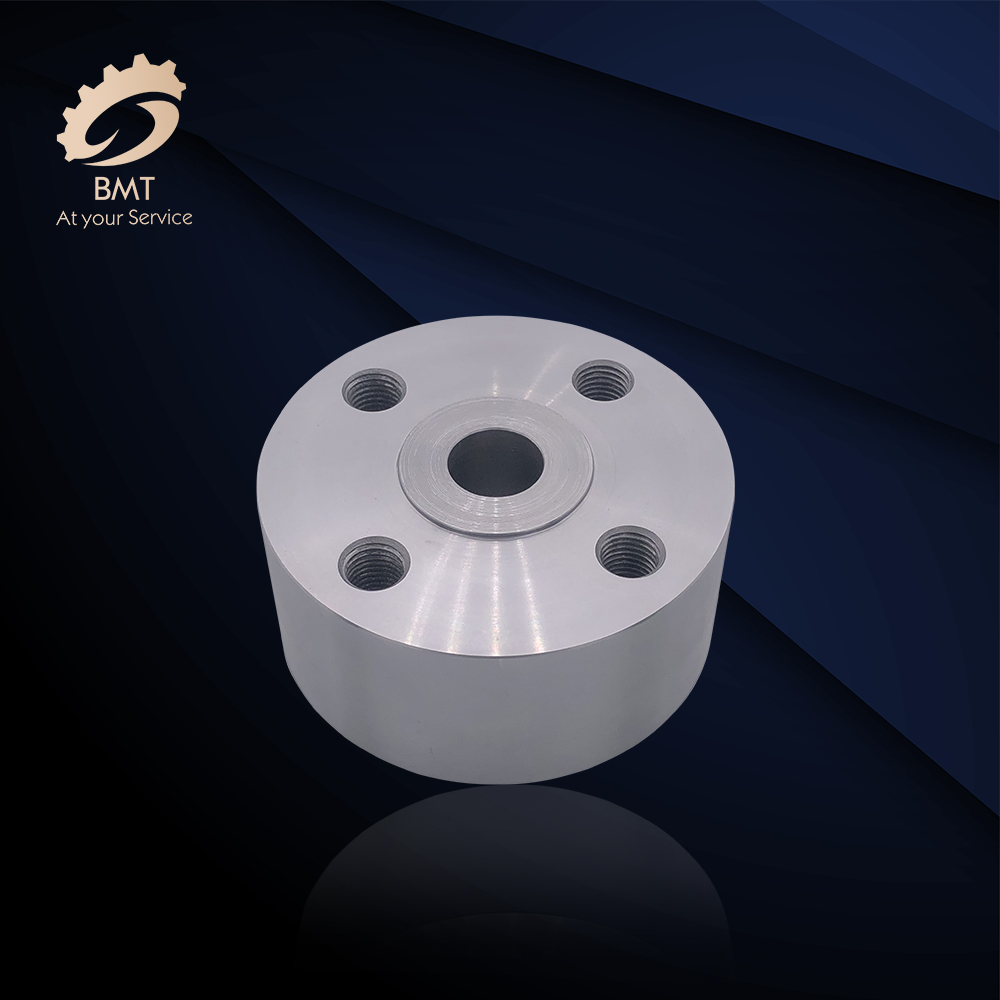

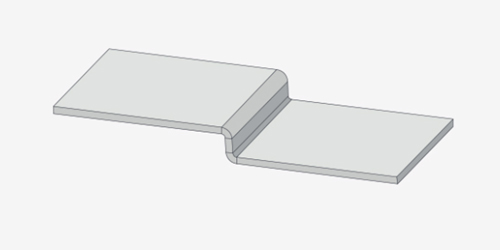

5. Offsets thiab Countersinks

Countersinks tuaj yeem ua los ntawm CNC Machining lossis tsim los ntawm cov cuab yeej tshwj xeeb. Kev kam rau tsim countersink loj txoj kab uas hla yog nruj heev, vim hais tias tej zaum nws yuav tsum tau siv nrog screws los yog fasteners. Offsets yog siv los tsim Z-zoo li tus profiles hauv cov ntawv hlau.

6. Ua tiav

Nyob ntawm daim ntawv thov thiab cov khoom siv, cov ntawv hlau tuaj yeem ua tiav nrog cov hlaws blasting, anodizing, plating, hmoov txheej thiab lwm yam txheej txheem, xws li rau kev ua haujlwm lossis tsuas yog txhim kho qhov zoo ntawm qhov.