Bending tseem ceeb ntawm cov ntawv hlau ua haujlwm

Txawm hais tias daim ntawv hlau dabtsi yog khoov zoo nkaus li yooj yim heev, nws zais ntau txoj cai thiab thev naus laus zis uas tso cai rau koj kom paub txog cov duab yooj yim lossis tsis tshua muaj. Cov ntawv hlau dabtsi yog khoov yog ib qho ntawm cov txheej txheem ntau tshaj plaws hauv kev tsim khoom.

Zoo ib yam li cov txheej txheem tsim, kev khoov ua haujlwm tsim kev hloov pauv hauv cov ntawv hlau. Piv txwv li, hloov ib daim ntawv tiaj tus hlau mus rau hauv daim ntawv angular. Qhov tseeb, los ntawm kev siv CNC xovxwm, pwm, dabtsi yog khoov tshuab lossis lwm yam tshuab, cov ntawv hlau tuaj yeem ncav cuag lub kaum sab xis.

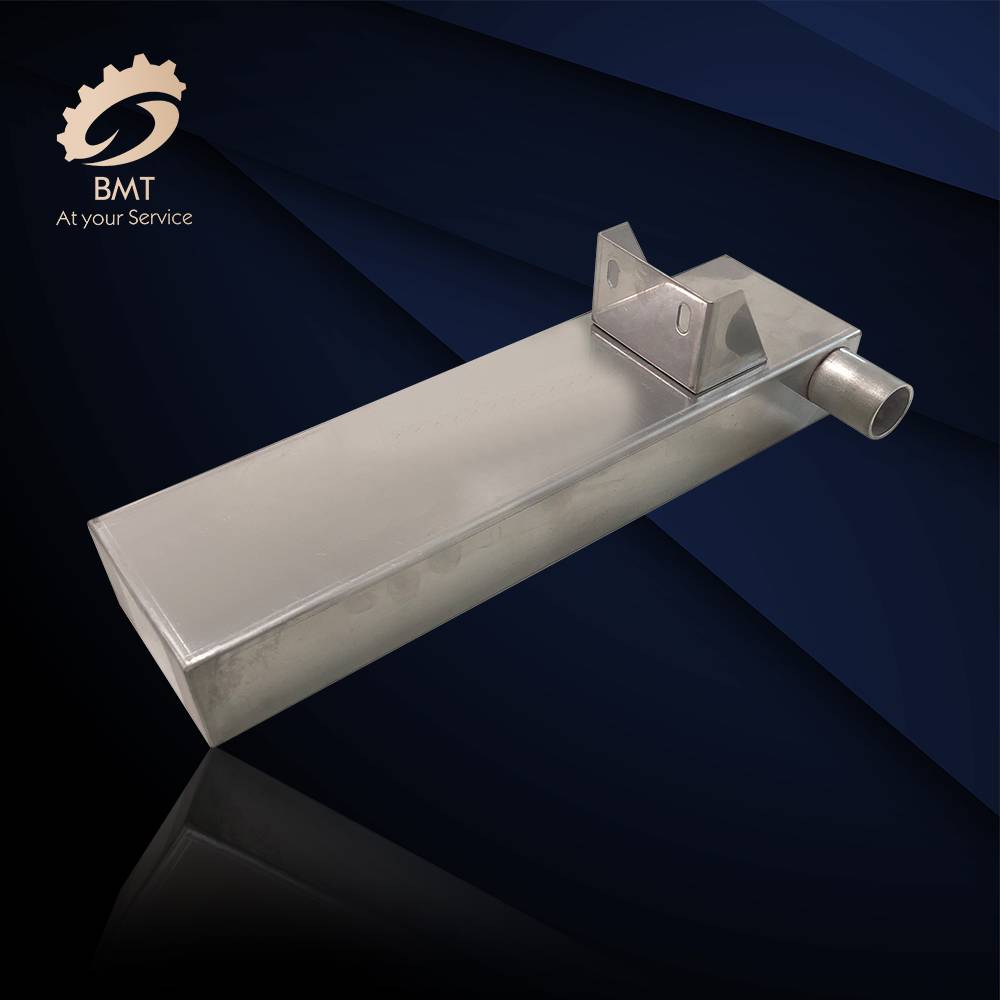

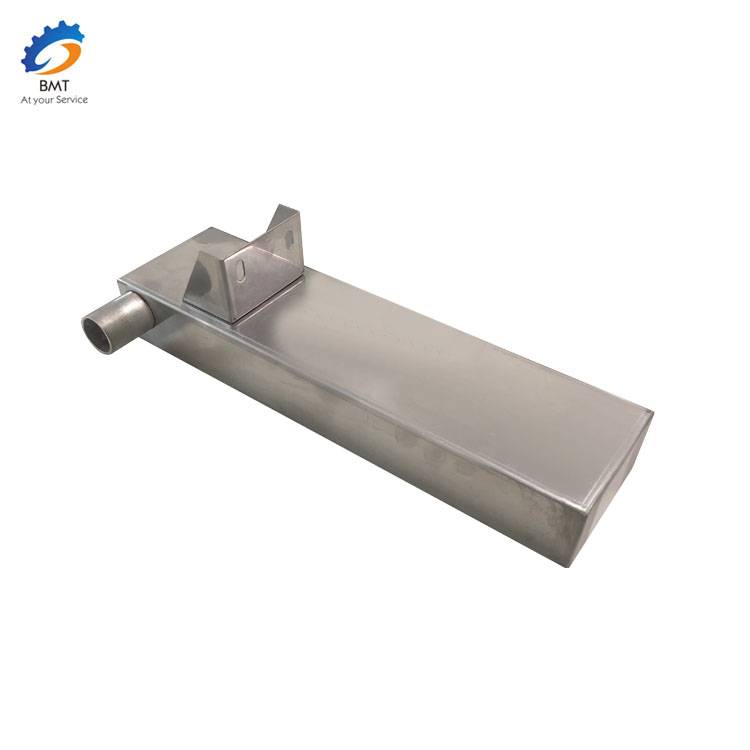

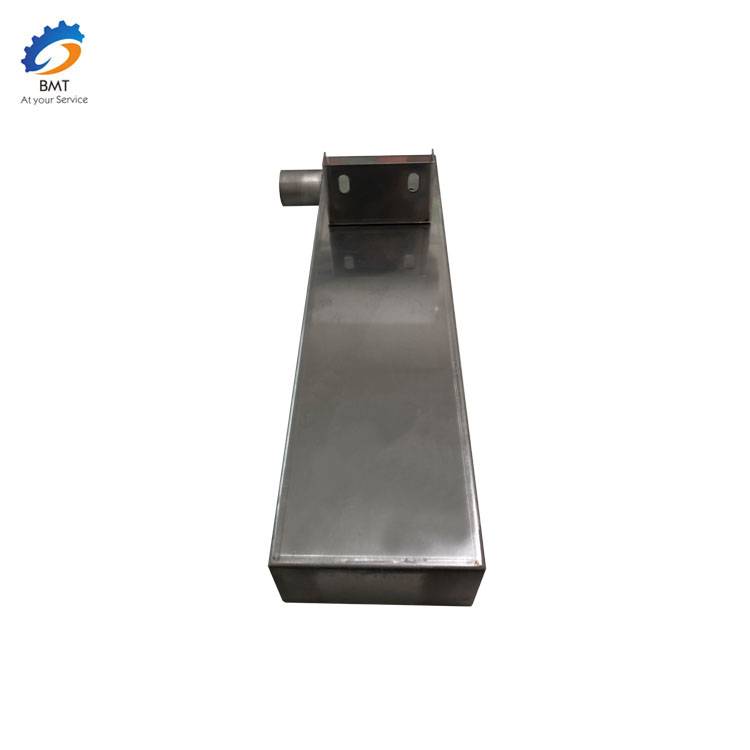

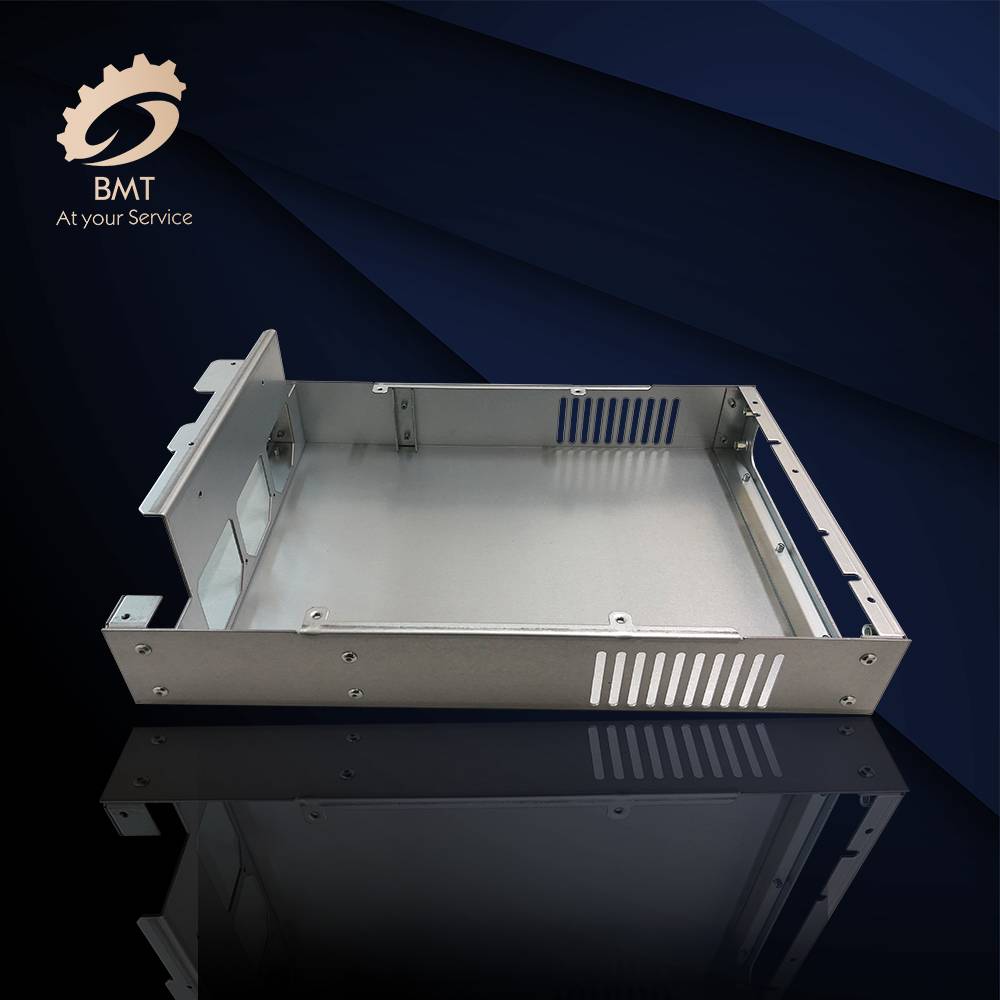

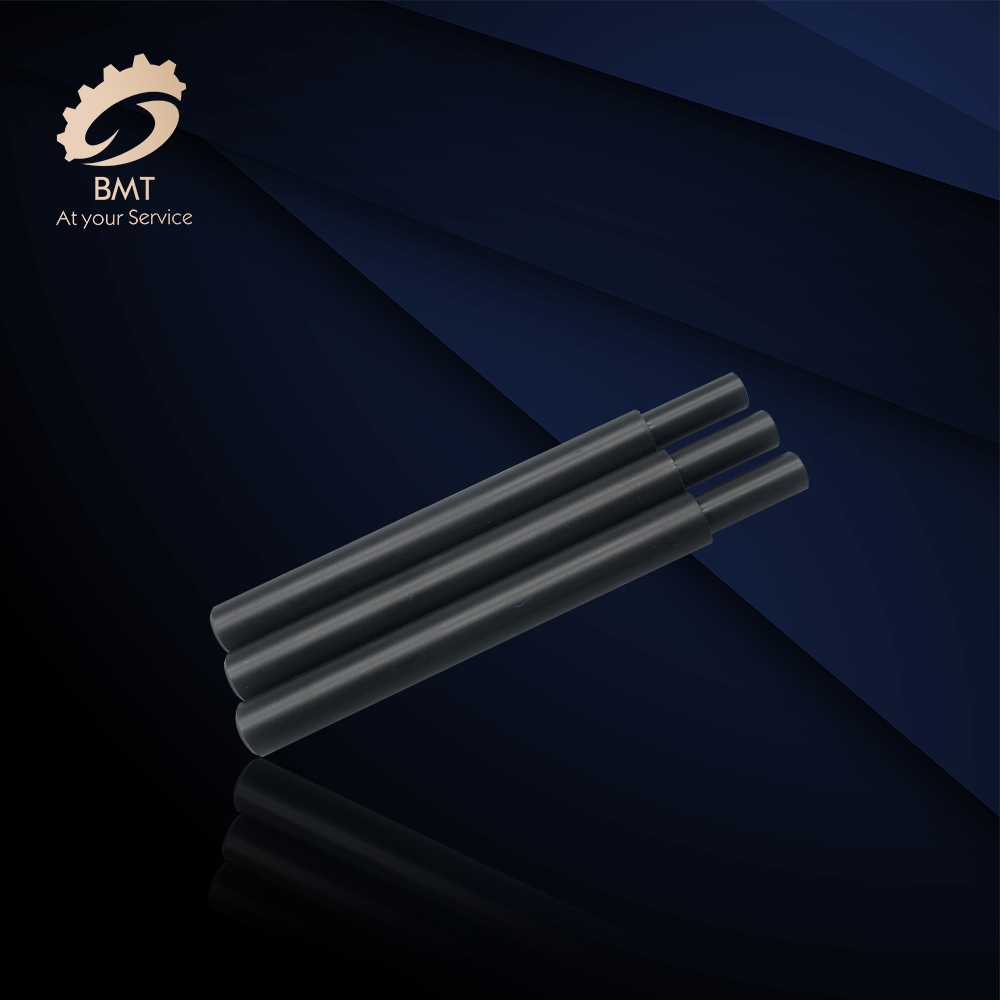

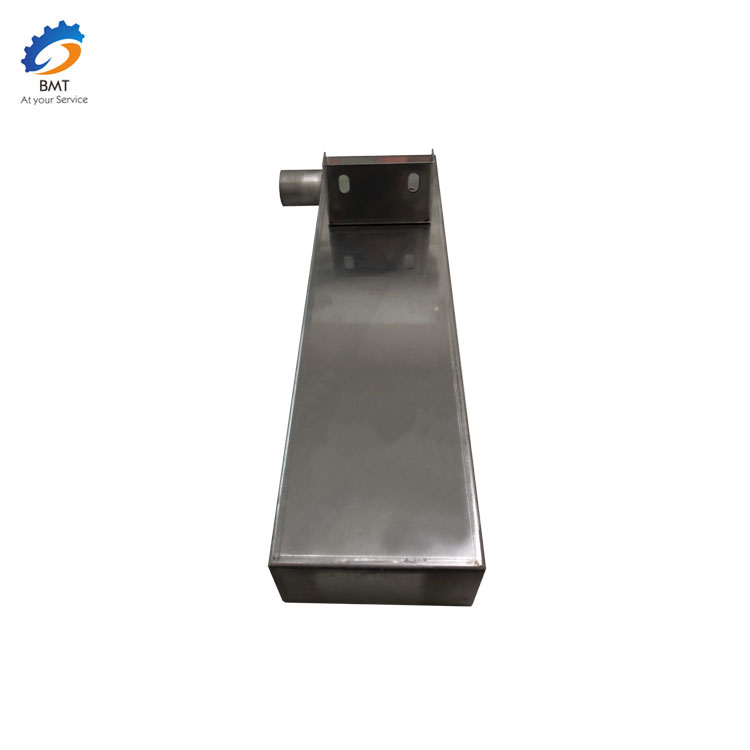

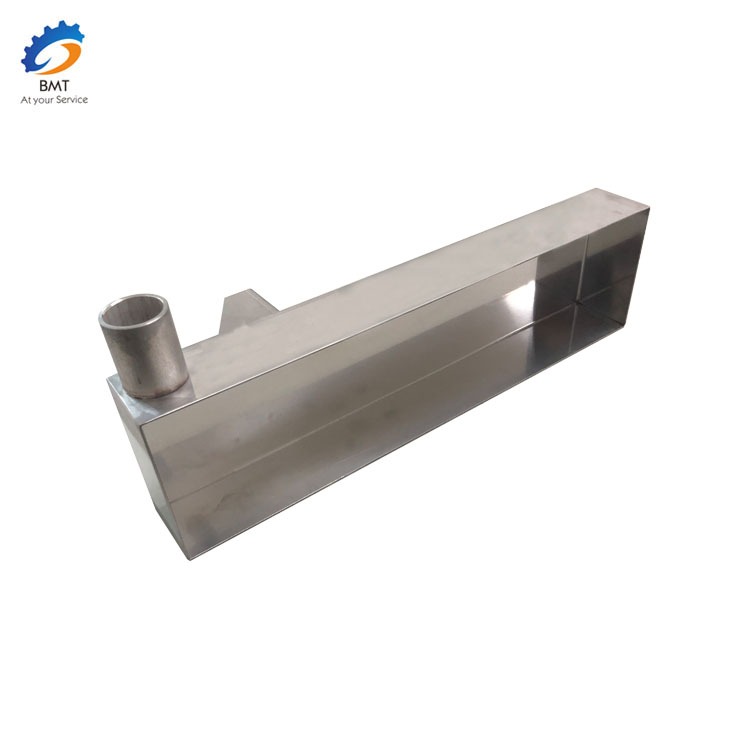

Sheet hlau fabrications yog txheej txheem uas tso cai rau koj kom paub cov duab yooj yim lossis tsis tshua muaj kev sib tw thiab tuaj yeem siv rau ntau hom hlau: los ntawm hlau mus rau tooj liab, tooj dag rau txhuas, los ntawm stainless hlau mus rau lwm yam tshwj xeeb alloys.

Thaum koj yuav tsum tau txiav txim siab txog hom dabtsi yog khoov, koj yuav tsum coj mus rau hauv tus account: lub thickness ntawm cov hlau, hom nkhaus, lub kaum sab xis ntawm khoov, thiab workpiece qhov ntev thiab lwm yam tseem ceeb cuam tshuam.

Ib txoj cai dav dav txog qhov no tuaj yeem yog: qhov loj dua yog qhov khoov, qhov qis qis qis ntawm cov pwm sab saud thiab qis dua. Hais txog cov teeb meem uas peb nyuam qhuav hais, koj tuaj yeem xaiv ntau hom kev khoov.

Muaj ntau yam uas tuaj yeem cuam tshuam qhov tshwm sim ntawmsheet hlau dabtsi yog khoov. Piv txwv li, qhov tseem ceeb tshaj plaws yog:

1. Cov khoom siv hlau

2. Kev ntxhov siab los ntawm cov txheej txheem dhau los

3. Hom ntawm ntug koj xav paub

4. Qhov ntev thiab tuab ntawm cov khoom ua haujlwm

5. Kev ua haujlwm kub

Muaj ntau qhov zoo ntawm Sheet Hlau Fabrication, suav nrog kev xaiv cov khoom siv (Aluminium, Copper, Stainless Steel thiab lwm yam), xaiv tiav (Bead Blasting, Anodizing, Plating, Hmoov Txheej, thiab lwm yam), xaiv thickness (raws li ntsuas), durability, scalability, ceev turnaround, thiab lwm yam. Yog xav paub ntxiv, thov saib hauv qab daim ntawv.

| NO | Yam khoom | NTAUB NTAWV |

| 1 | Khoom siv | Aluminium, Hlau, tooj dag, tooj liab, Stainless hlau, Yas, POM, Derlin, Titanium Alloy, thiab lwm yam. |

| 2 | Kev kho saum npoo | Zinc plating, Anodization, tshuaj zaj duab xis, hmoov txheej, Passivation, Sand blasting, Txhuam & polishing, thiab lwm yam. |

| 3 | Cov cuab yeej ua haujlwm | Cnc Machining Center, CNC tshuab dhos, Sib tsoo tshuab, Tsis siv neeg tshuab dhos, tshuab dhos tshuab, Milling tshuab, EDM, thiab lwm yam. |

| 4 | Cov cuab yeej tshuaj xyuas | 3D CMM; 2.5D dluab ntsuas ntsuas, Roughness meter, swb caliper, micrometers, gauge thaiv, dial taw qhia, xov gauge, universal lub kaum sab xis txoj cai, thiab lwm yam. |

| 5 | Peb Cov Kev Pabcuam | CNC Machining, Milling, Tig, Sib Tsoo, Stamping, Punching, thiab sib dhos, thiab lwm yam. |

| 6 | QC System | 100% kev soj ntsuam ua ntej xa khoom xa tuaj, Kev tshuaj xyuas thib peb muaj nyob ntawm qhov kev thov. |

| 7 | Ntim | Ua npuas ncauj, Carton, Ntoo thawv, raws li kev cai. |

| 8 | Cov nqe lus them nqi | 30% T / T ua ntej, 70% tshuav nyiaj ua ntej xa khoom. |

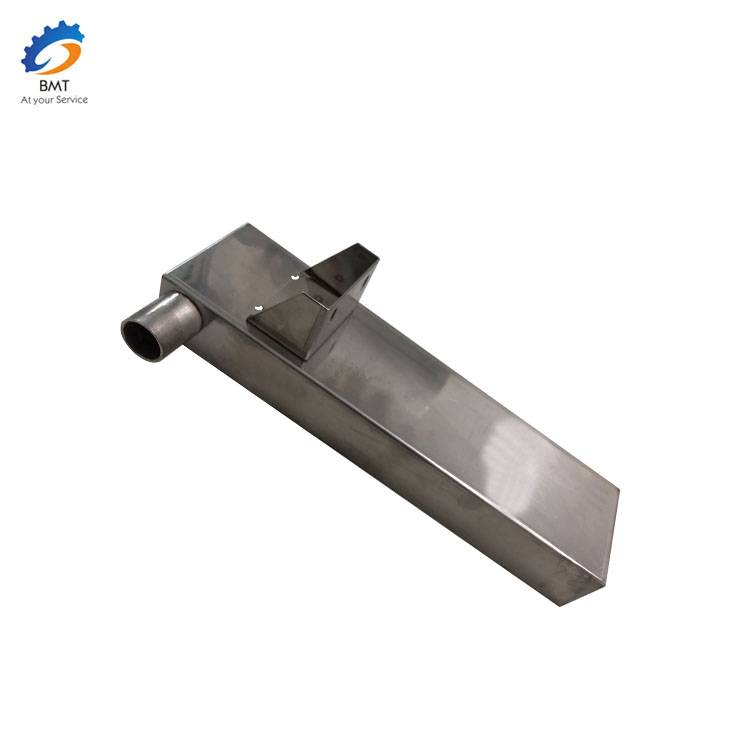

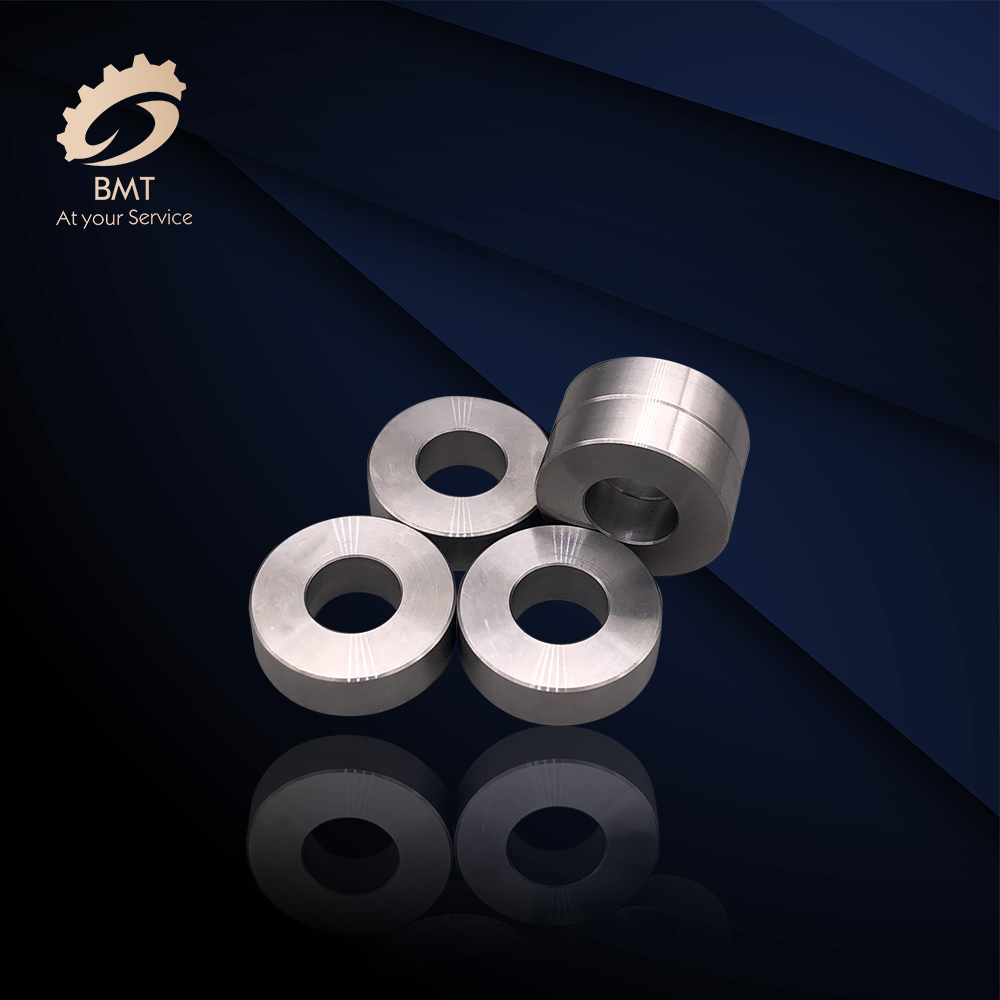

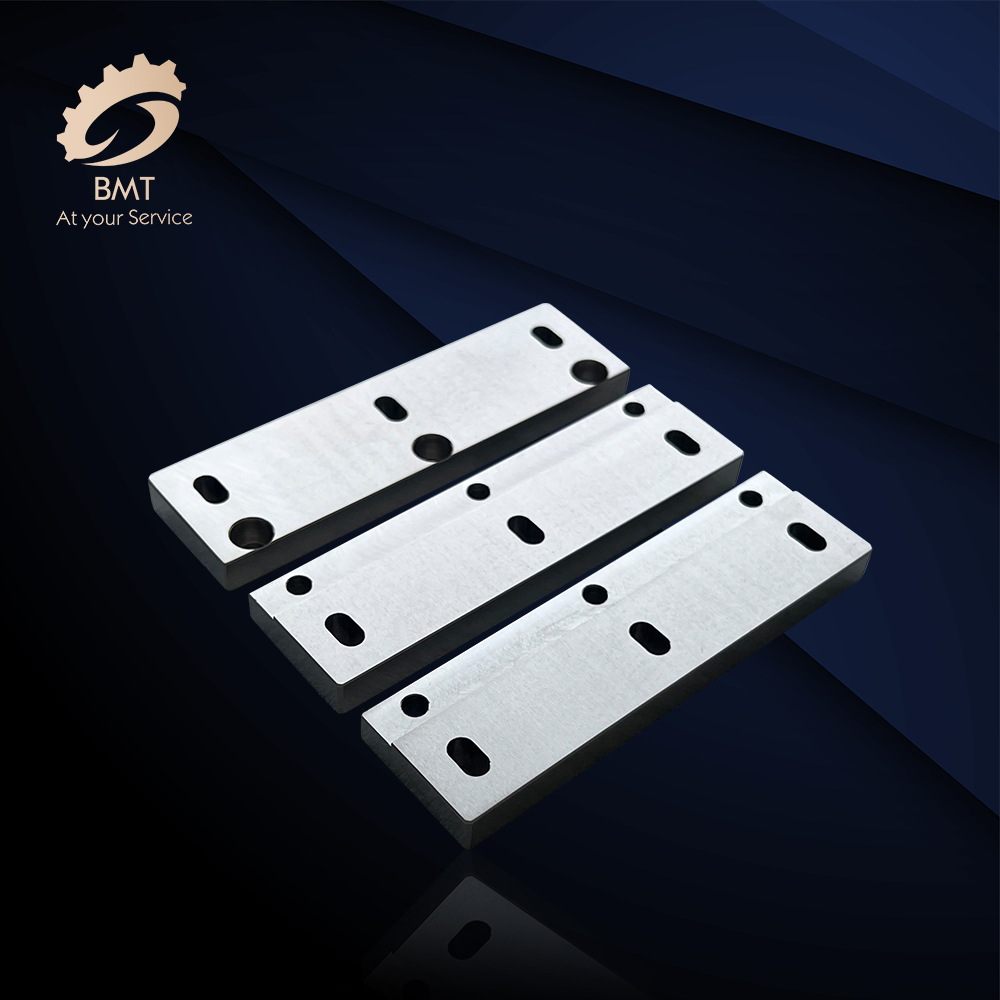

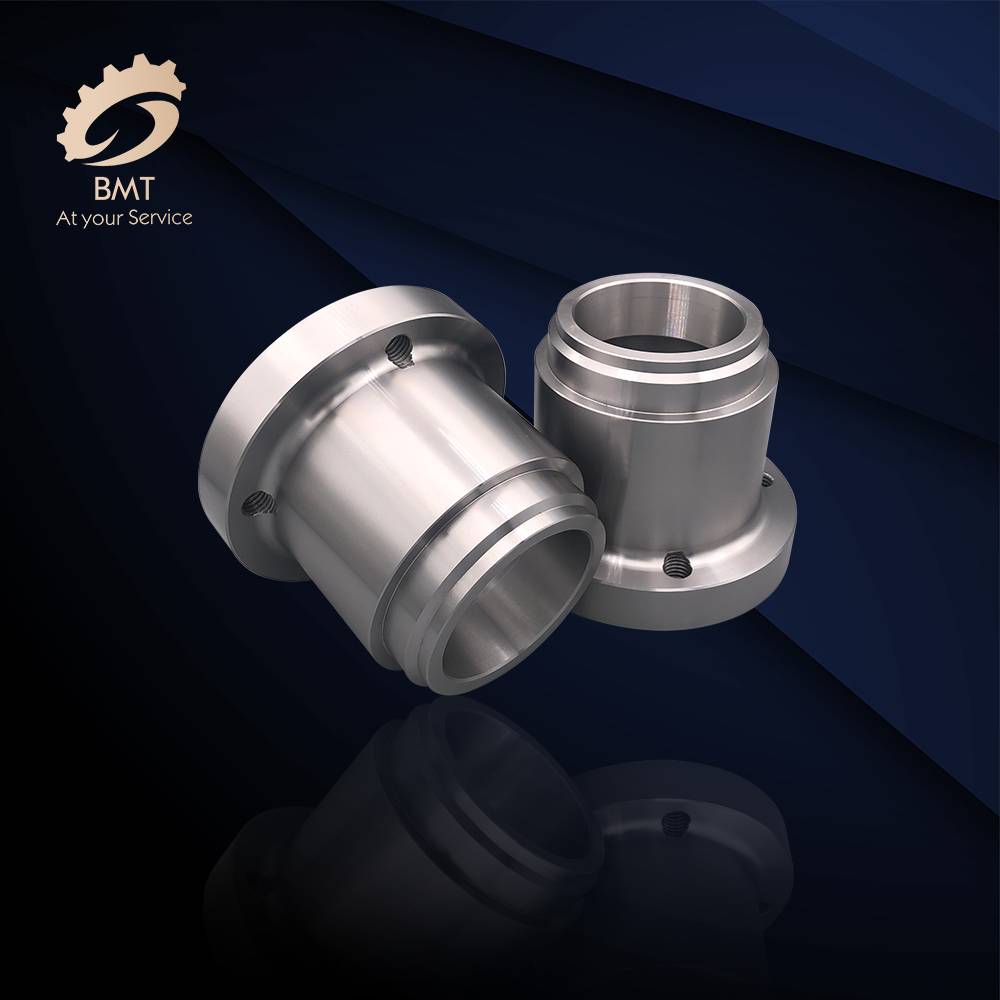

| 9 | Yam khoom Scope | CNC machining / tig qhov chaw, Jig & Fixture Tsim thiab Ua, Sheet Hlau Parts thiab Stamping Parts. |

| 10 | Daim ntawv thov | Automation tshuab, muaj tshuab, khoom siv hluav taws xob, Auto Parts, Furniture Parts, Machinery Parts, Light fittings, etc. |

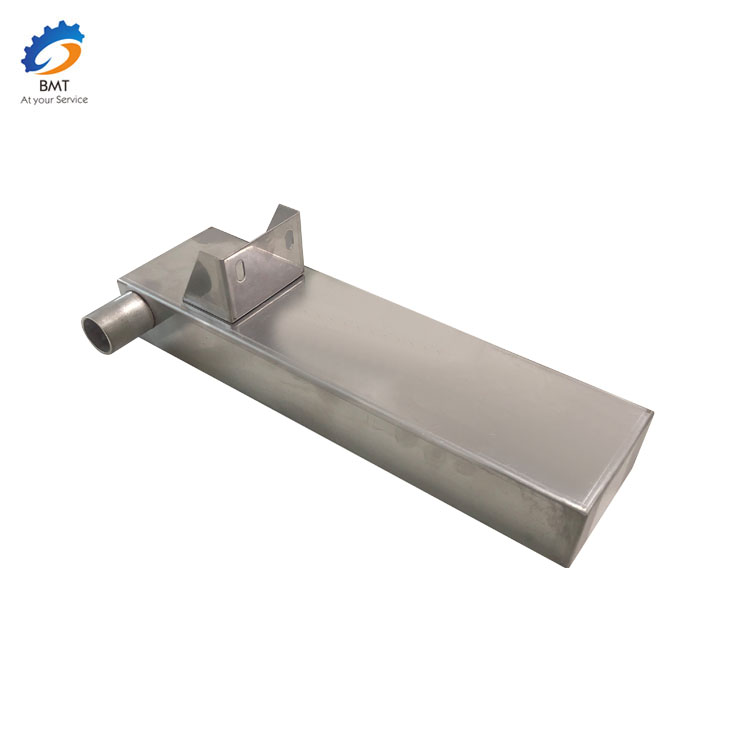

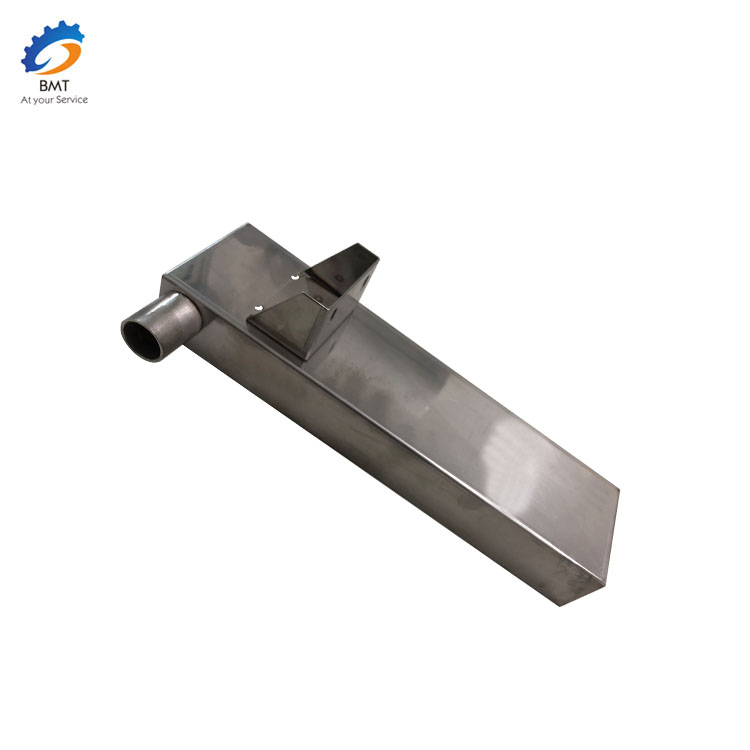

Product Description

Qee Cov Khoom Peb Ua