Titanium Alloy Mechanical Properties

Titanium alloy muaj lub zog siab thiab qhov ntom ntom, cov khoom siv zoo, zoo toughness thiab corrosion kuj. Tsis tas li ntawd, titanium alloy txheej txheem kev ua haujlwm tsis zoo, txiav nyuaj, hauv kev ua haujlwm kub, yooj yim heev rau nqus cov pa oxygen nitrogen carbon thiab lwm yam impurities. Muaj kev hnav tsis zoo, txheej txheem ntau lawm. Kev lag luam tsim khoom ntawm titanium pib xyoo 1948. Kev tsim kho ntawm kev lag luam aviation xav tau, kom titanium kev lag luam nrog qhov nruab nrab txhua xyoo kev loj hlob ntawm li 8% kev loj hlob.

Tam sim no, cov khoom tsim tawm txhua xyoo ntawm titanium alloy ua khoom hauv ntiaj teb tau mus txog ntau dua 40,000 tons, thiab ze li ntawm 30 hom titanium alloy qib. Feem ntau siv titanium alloys yog Ti-6Al-4V (TC4), Ti-5Al-2.5Sn (TA7) thiab muaj titanium ntshiab (TA1, TA2 thiab TA3).

Titanium alloys feem ntau yog siv los ua compressor qhov chaw rau cov tshuab dav hlau, ua raws li cov qauv tsim rau cov foob pob hluav taws, cuaj luaj thiab cov dav hlau ceev. Los ntawm nruab nrab-1960s, titanium thiab nws cov alloys tau siv nyob rau hauv kev lag luam dav dav los ua cov electrodes rau electrolysis, condensers rau fais fab chaw nres tsheb, cua sov rau roj refining thiab desalination, thiab cov pa phem. Titanium thiab nws cov alloys tau dhau los ua ib hom kev tiv thaiv corrosion-resistant cov ntaub ntawv. Tsis tas li ntawd, nws kuj yog siv los tsim cov khoom siv hydrogen cia thiab cov duab nco alloys.

Tuam Tshoj pib tshawb fawb txog titanium thiab titanium alloys hauv xyoo 1956; Nyob rau hauv nruab nrab ntawm xyoo 1960, kev tsim cov khoom siv titanium thiab kev loj hlob ntawm TB2 alloy pib. Titanium alloy yog cov khoom siv tseem ceeb tshiab siv hauv kev lag luam aerospace. Nws qhov tshwj xeeb lub ntiajteb txawj nqus, lub zog thiab kev pabcuam kub yog nruab nrab ntawm txhuas thiab hlau, tab sis nws lub zog tshwj xeeb yog siab thiab nws muaj kev tiv thaiv dej hiav txwv zoo heev thiab kev ua haujlwm kub qis.

Xyoo 1950, F-84 fighter-bomber yog thawj zaug siv los ua lub nraub qaum fuselage heat shield, air hood, tail hood, and other non-bearing components. Txij li thaum xyoo 1960, kev siv cov titanium alloy tau txav los ntawm lub fuselage rear mus rau nruab nrab fuselage, ib nrab hloov cov qauv hlau los ua cov khoom tseem ceeb xws li thav duab, beam thiab flap swb. Kev siv titanium alloy hauv cov tub rog dav hlau tau nce sai, ncav cuag 20% ~ 25% ntawm qhov hnyav ntawm cov qauv dav hlau.

Xa koj cov lus rau peb:

-

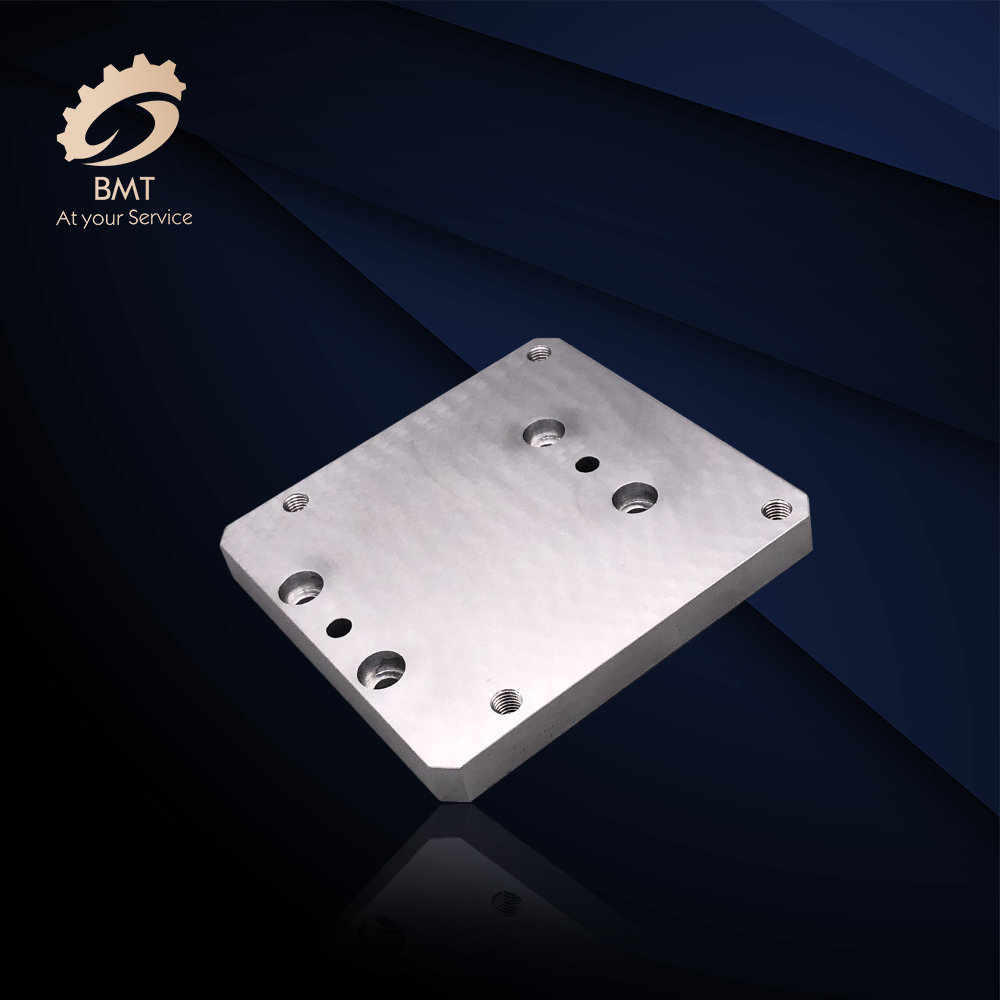

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes