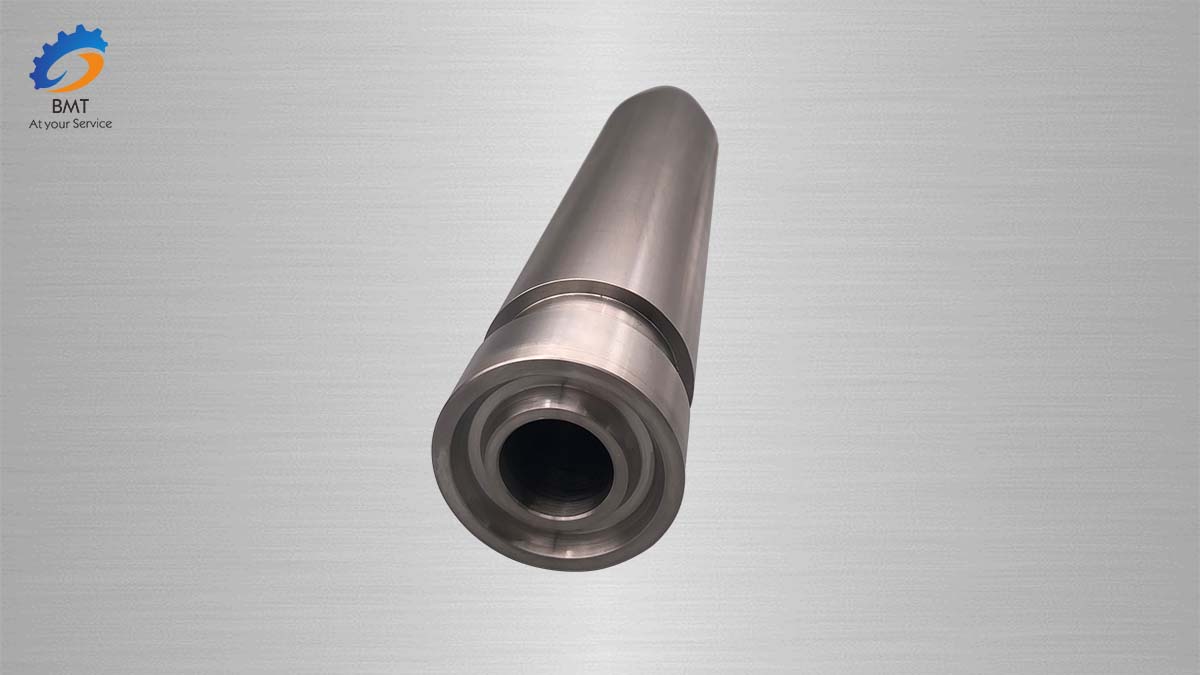

Titanium Alloy CNC Machining qhov chaw

Lub siab machining ntawm titanium alloys zoo ib yam li steel machining dua li cov hlau tsis muaj hlau thiab alloys. Ntau cov txheej txheem tsis sib xws ntawm titanium alloys hauv forging, ntim stamping thiab daim ntawv stamping yog ze rau cov hauv kev ua hlau. Tab sis muaj qee qhov tseem ceeb uas yuav tsum tau them nyiaj rau thaum nias ua haujlwm Chin thiab Chin alloys.

Txawm hais tias nws yog feem ntau ntseeg tias hexagonal lattices muaj nyob rau hauv titanium thiab titanium alloys yog tsawg dua ductile thaum deformed, ntau yam xovxwm ua hauj lwm txoj kev siv rau lwm yam qauv hlau kuj haum rau titanium alloys. Qhov piv ntawm cov txiaj ntsig taw tes rau lub zog txwv yog ib qho ntawm cov yam ntxwv qhia txog seb cov hlau puas tuaj yeem tiv taus cov yas deformation. Qhov loj dua qhov piv txwv no, qhov phem tshaj qhov plasticity ntawm cov hlau. Rau kev lag luam ntshiab titanium hauv lub xeev txias, qhov sib piv yog 0.72-0.87, piv rau 0.6-0.65 rau carbon hlau thiab 0.4-0.5 rau stainless hlau.

Nqa tawm ntim stamping, pub dawb forging thiab lwm yam kev ua haujlwm uas cuam tshuam nrog kev ua haujlwm ntawm cov hlaws loj thiab cov khoob loj loj hauv lub xeev rhuab (saum toj no qhov kub hloov pauv = yS). Qhov kub ntawm forging thiab stamping cua sov yog nruab nrab ntawm 850-1150 ° C. Alloys BT; M0, BT1-0, OT4 ~ 0 thiab OT4-1 muaj kev txaus siab ntawm cov yas deformation hauv lub xeev txias. Yog li ntawd, cov khoom ua los ntawm cov alloys feem ntau yog ua los ntawm nruab nrab annealed blanks tsis muaj cua sov thiab stamping. Thaum cov titanium alloy yog txias plastically deformed, tsis hais nws cov tshuaj muaj pes tsawg leeg thiab txhua yam khoom, lub zog yuav zoo dua, thiab cov yas yuav raug txo kom tsawg. Vim li no, kev kho annealing ntawm cov txheej txheem yuav tsum tau ua.

Kev hnav ntawm qhov ntxig zawj hauv machining ntawm titanium alloys yog qhov hnav hauv zos ntawm lub nraub qaum thiab pem hauv ntej ntawm qhov tob ntawm kev txiav, uas feem ntau tshwm sim los ntawm txheej txheej hardened los ntawm kev ua dhau los. Cov tshuaj lom neeg cov tshuaj tiv thaiv thiab diffusion ntawm lub cuab yeej thiab cov khoom siv ua haujlwm ntawm qhov kub ntawm ntau tshaj 800 ° C kuj yog ib qho laj thawj rau kev tsim cov groove hnav. Vim hais tias thaum lub sij hawm machining txheej txheem, titanium molecules ntawm lub workpiece sau nyob rau hauv pem hauv ntej ntawm cov hniav thiab yog "welded" rau cov hniav ntug nyob rau hauv lub siab thiab kub kub, tsim ib tug built-up ntug. Thaum cov ntug tsim-up tev tawm ntawm ntug txiav, cov carbide txheej ntawm cov ntxig yog muab tshem tawm.

Vim lub tshav kub tsis kam ntawm titanium, cua txias yog qhov tseem ceeb hauv cov txheej txheem machining. Lub hom phiaj ntawm kev ua kom txias yog ua kom cov ntug txiav thiab cov cuab yeej nto los ntawm overheating. Siv cov dej txias kawg rau qhov zoo tshaj plaws nti khiav tawm thaum ua lub xub pwg milling nrog rau lub ntsej muag milling hnab ris, hnab ris lossis tag nrho cov grooves. Thaum txiav titanium hlau, cov chips yooj yim los lo rau ntawm ntug txiav, ua rau cov kab tom ntej ntawm milling cutter txiav cov chips dua, feem ntau ua rau cov ntug kab rau nti.

Txhua qhov ntxig kab noj hniav muaj nws lub qhov dej txias / txhaj tshuaj los daws qhov teeb meem no thiab txhim kho qhov kev ua haujlwm tas li. Lwm qhov zoo huv si yog threaded txias qhov. Ntev ntug milling cutters muaj ntau qhov ntxig. Kev siv cov dej txias rau txhua lub qhov yuav tsum muaj lub twj tso kua mis siab thiab siab. Ntawm qhov tod tes, nws tuaj yeem ntsaws cov qhov tsis xav tau raws li qhov xav tau, yog li ua kom txaus siab rau lub qhov uas xav tau.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes