Txoj hauv kev kom tau txais kev hloov pauv thiab hloov kho tshiab 3

Qhov thib plaub yog kom paub txog remanufacturing technology. Pib los ntawm ob yam ntawm cov khoom siv ntxiv thiab kev ua tau zoo ntawm qhov ua tsis tau zoo, cov cuab yeej siv qub qub thiab cov khoom tseem ceeb yuav raug kho nyob rau hauv ib pawg kws tshaj lij, kom cov khoom tuaj yeem ncav cuag qhov zoo thiab kev ua tau zoo ib yam li cov khoom qub tshiab, thiab txhawb cov khoom lag luam. kev lag luam ncig kev lag luam thiab kev siv peev txheej kev koom ua ke.

Thib tsib, tsom mus rau kev txhim kho ntawm cov khoom tseem ceeb thiab cov thev naus laus zis. Kev tshawb fawb tsom mus rau cov khoom tseem ceeb ntawm kev tsim kho tshuab yuav tsum tsom rau lub cav, hydraulic, kis tau tus mob thiab tswj cov tshuab. Ntawm lawv, lub cav yuav tsum tsis tu ncua txhim kho cov roj txhaj tshuaj thiab cov thev naus laus zis xws li kev txo qis roj thiab cov pa roj carbon tsawg, thiab ntxiv dag zog rau kev ua haujlwm ntawm lub zog cia thiab lub zog tso tawm hom, kev ua tau zoo sib xws, kev vibration thiab suab nrov ntawm qis ceev. Cov khoom sib kis tshwj xeeb tsom rau "ob chav sib txawv" thiab lub ntiaj teb slewing reducer, tsav qag thiab ncua kev kaw lus, slewing bearing, "plaub lub log thiab ib txoj siv", thiab lwm yam. los txhim kho lub sealing ntawm lub load spectrum nyob rau hauv kev ua hauj lwm tej yam kev mob xeem txoj kev.

daws cov kev tsis sib haum xeeb ntawm cov khoom siv hluav taws xob siab thiab cov hydraulic loj, txhim kho kev ywj pheej tsim thiab tsim muaj peev xwm ntawm cov twj hydraulic, hydraulic li qub, hydraulic motors thiab hydraulic cylinders, thiab paub batch txuam sai li sai tau. Paub txog cov dej ntws txuas ntxiv ntawm cov saw hlau ua lag luam. Lub tshuab tsim kev lag luam muaj cov saw hlau ntev ntev, tshwj xeeb tshaj yog cov khoom siv hluav taws xob txuas ntxiv, uas yog ib feem tseem ceeb ntawm cov saw hlau ntawm kev lag luam no. Hauv kev lag luam loj thiab rov ua lag luam steel, cov tuam txhab tsim khoom lag luam tau tsim kev lag luam zoo nrog cov neeg xa khoom steel, thiab cov tuam txhab tsim khoom feem ntau tuaj yeem tau txais cov hlau loj ntawm cov nqi zoo.

Hauv qhov no, yog tias cov chaw tsim khoom lag luam tuaj yeem muag cov hlau yuav los ntawm tus nqi qis ntawm tus nqi siab, uas yog, txhawm rau ua cov lag luam steel, lawv tuaj yeem khwv tau nyiaj ntau heev los ntawm cov hlau thiab paub txog cov txiaj ntsig tau nce hauv cov dej ntws. kev lag luam saw. Yog li ntawd, nws yog ib txoj hauv kev zoo rau cov tuam txhab tsim khoom siv los ua kom zoo dua ntawm cov neeg siv khoom los ua txoj haujlwm zoo hauv kev txheeb xyuas cov saw hlau, txuas ntxiv rau cov saw hlau ua lag luam, thiab ua kom muaj kev lag luam cuam tshuam.

Tam sim no, qhov qub qub ntawm kev txhim kho kev lag luam yuav txuas ntxiv mus. Kev hloov pauv thiab hloov kho dua tshiab ntawm kuv lub teb chaws cov tshuab tsim khoom lag luam yog qhov tseem ceeb thiab yuav tshwm sim.

Tsuav peb ua raws li tsib lub tswv yim ntawm kev tsim kho tshiab, kev sib koom tes, ntsuab, kev qhib siab thiab kev sib koom, ua raws li kev tsim kho kom ruaj khov, thiab coj txoj kev loj hlob ntawm kev hloov pauv thiab kev txhim kho, peb yuav muaj peev xwm ua rau kuv lub teb chaws cov tshuab tsim kev lag luam loj dua thiab muaj zog, thiab paub txog kev hloov pauv ntawm kev tsim khoom siv tshuab los ntawm kev tsim khoom. Kev hloov pauv los ntawm cov qauv tsim khoom mus rau cov qauv kev pabcuam ntau lawm, kev hloov pauv los ntawm kev tswj hwm dav dav mus rau kev tswj hwm lean, thiab kev hloov pauv los ntawm kev tsim khoom qis kawg mus rau high-end manufacturing.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

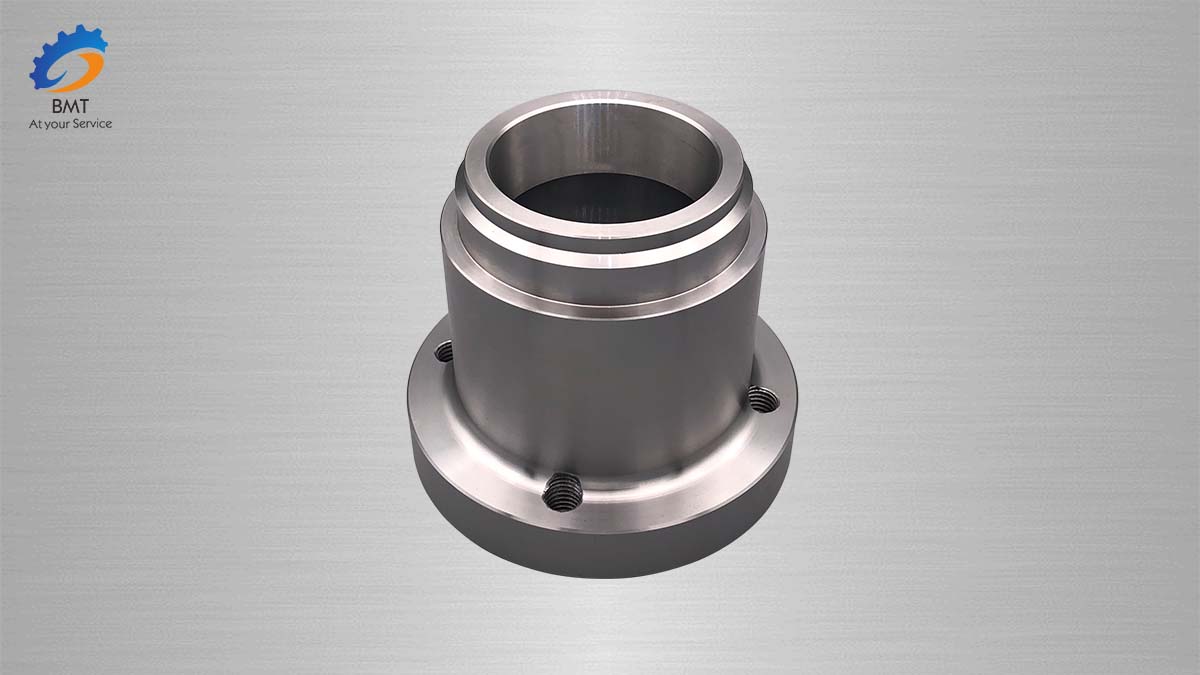

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes