Peb tau cog lus los muab cov nqi sib tw, cov khoom tshwj xeeb thiab cov kev daws teeb meem zoo, ib yam nkaus li xa khoom sai rau Tuam Tshoj Dongguan Chaw Tsim Tshuaj High Precision CNC Auto Parts CNC Milling Tshuab Cheebtsam, Saib mus rau yav tom ntej, txoj kev ntev mus, tsis tu ncua siv zog los ua txhua tus neeg ua haujlwm nrog kev txaus siab tag nrho, ib puas npaug ntawm kev ntseeg siab thiab muab peb lub tuam txhab tsim kom muaj ib puag ncig zoo nkauj, cov khoom lag luam siab heev, zoo thawj chav kawm niaj hnub kev lag luam thiab ua haujlwm nyuaj!

Peb tau cog lus los muab cov nqi sib tw, cov khoom tshwj xeeb thiab cov kev daws teeb meem zoo, ib yam nkaus li xa khoom sai rauTuam Tshoj Cnc Machined Aluminium Parts, CNC Aluminium Part, Raws li ib pab pawg neeg muaj kev paub dhau los peb kuj lees txais kev txiav txim siab thiab ua kom zoo ib yam li koj daim duab lossis cov qauv kev qhia tshwj xeeb thiab cov neeg siv khoom tsim khoom. Lub hom phiaj tseem ceeb ntawm peb lub tuam txhab yog tsim kom muaj lub cim xeeb txaus siab rau txhua tus neeg siv khoom, thiab tsim kom muaj kev sib raug zoo ntawm kev lag luam ntev-yeej. Xaiv peb, peb ib txwm tos koj lub ntsej muag!

Shorten Your Production Cycle

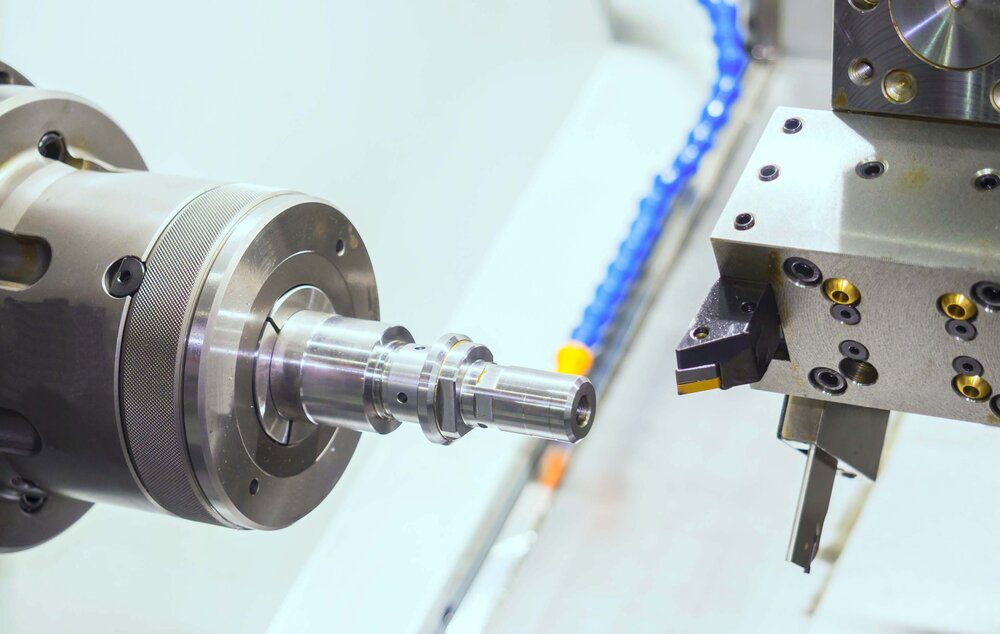

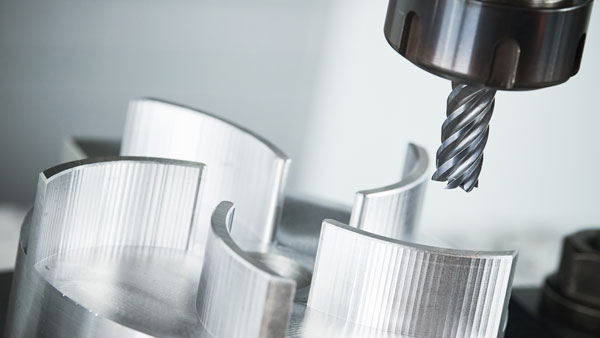

Cov txheej txheem tsim khoom no yog lub tshuab ua haujlwm siab uas siv lub khoos phis tawj-pab tsim software thiab khoos phis tawj-pab tsim. Rau qhov chaw nrog cov qauv tsim yooj yim, tus neeg teb xov tooj tuaj yeem nkag ncaj qha rau cov lus txib hauv lub tshuab. Tab sis rau kev tsim qauv nyuaj, CAM lossis CAD daim duab yuav tsum tau tsim ua ntej thiab muab tso rau hauv qhov system. Lwm txoj hauv kev yog siv Coordinate Measuring Machines (CMMs) rau lub cev daim ntawv qhia cov lus qhia ntawm kev tsim rau hauv lub cev. Lub software yuav tsim thiab muab cov kauj ruam xav tau rau lub tshuab txiav los tsim cov khoom peb xav tau.

Muaj tsawg chav rau kev ua yuam kev vim tias lub tshuab yuav ua raws li cov lus qhia hauv tsab ntawv los tsim cov khoom. Dab tsi yog qhov zoo dua yog tias qhov kev ua haujlwm no yog rov ua dua, uas tso cai rau kev tsim khoom sai dua ntawm cov khoom sib xws.

Cov ntawv thov ua ntej ntawm CNC tshuab qeeb qeeb thiab tsuas yog ua haujlwm rau cov khoom ntim siab. Tam sim no, hauv BMT, thev naus laus zis tau txhim kho zoo heev. Siv cov software nyuaj thiab cov cuab yeej, nws tso cai rau kev sib koom ua ke ncaj qha ntawm cov qauv tsim hauv computer rau qhov kev pab cuam rau cov txheej txheem kom sai dua. Qhov no kuj tso cai rau siv CNC machining cov kev pab cuam rau cov ntim tsawg yuav tsum tau pheej yig dua thiab siv tau.

Tsis muaj teeb meem dab tsi hauv kev lag luam koj nyob hauv lossis qhov koj xav tau yog dab tsi, nrog kev siv peb cov kev pabcuam CNC machining sab saum toj, peb tuaj yeem ua cov qauv, kev txiav txim me me, thiab cov khoom ntim tsawg. Peb lub tuam txhab ua ke nrog kev siv cov cuab yeej siv thev naus laus zis, kev siv tshuab siab heev, thiab cov kws tshaj lij engineers thiab peb tuaj yeem xa cov khoom kom tshaj qhov koj xav tau. CNC tshuab peb muaj tuaj yeem tiv taus huab cua thiab ib puag ncig rau ntau daim ntawv thov hauv yuav luag txhua qhov kev lag luam.

Cov khoom siv hlau thiab yas

Cov hlau thiab cov ntaub ntawv yas peb feem ntau ua haujlwm tau teev tseg hauv qab no thiab koj tuaj yeem xaiv raws li koj xav tau:

| Hlau | TXOJ CAI | ADVANTAGES & CONSIDERATIONS | THOV & TEEB MEEM |

| Stainless hlau | +/- 0.005 " | Siab zog Siab Corrosion Resistance Siab Weldability | Standard Machined tiav nrog cov neeg siv khoom zoo li thov, zoo li plating, anodizing, blasting, thiab lwm yam. |

| Carbon Steel | +/- 0.005 " | High Machinability Siab Weldability Yuav Hardened Tsis Corrosion Resistant | |

| Aluminium | +/- 0.005 " | High StrengthHigh Strength Qhov hnyav High Machinability Tus nqi qis | |

| tooj dag | +/- 0.005 " | Siab zog Qhov hnyav High Machinability Tus nqi qis |

| Plastics | TXOJ CAI | ADVANTAGES & CONSIDERATIONS | THOV & TEEB MEEM |

| HDPE | +/- 0.008 " | Nruab nrab Impact Strength Yooj yim | Standard Machined tiav |

| PC | +/- 0.008 " | Nruab nrab Tensile Lub zog muaj zog Khaws Cov Khoom Tshaj Kub High Optical Clarity | |

| ABS | +/- 0.008 " | Nruab nrab Tensile Lub zog muaj zog Hluav taws xob Insulator High Machinability Tus nqi qis | |

| Acrylic | +/- 0.008 " | Siab Tensile zog Yuav Polished | |

| Nylon | +/- 0.008 " | Siab Tensile Nruab nrab Impact Strength Khaws Cov Khoom Tshaj Kub | |

| Delrin | +/- 0.008 " | Nruab nrab Tensile Nruab nrab Impact Strength Tuav Machining Tolerances Zoo Zoo hnav & qaug zog ua haujlwm | |

| ULTEM | +/- 0.008 " | Siab Tensile zog Kub ua haujlwm siab Hluav taws xob Insulator High Optical Clarity |

Koj puas xav kom luv luv lub voj voog ntau lawm thiab txo koj cov nqi tsim khoom tag nrho?

BMT muaj txoj kev daws teeb meem. Yooj yim rau kev tsim cov txheej txheem nrog CNC machining cov kev pabcuam, uas tuaj yeem pab koj ua kom cov khoom ntim loj loj nrog cov qib siab tshaj plaws thiab raug.

Hauv kev tsim khoom niaj hnub no, outsourcing yog qhov tseem ceeb. BMT tuaj yeem muab rau koj nrog ceev CNC machining raws li koj cov kev xav tau tshwj xeeb. Txhua yam koj yuav tsum tau ua yog xa cov ntaub ntawv CAD lossis xa cov lus nug rau peb tus email. Peb muab koj cov lus qhia ceev thiab pub dawb rau CNC machining cov kev pabcuam thiab tau txais koj cov khoom ua tiav hauv lub sijhawm luv tshaj plaws.

Product Description

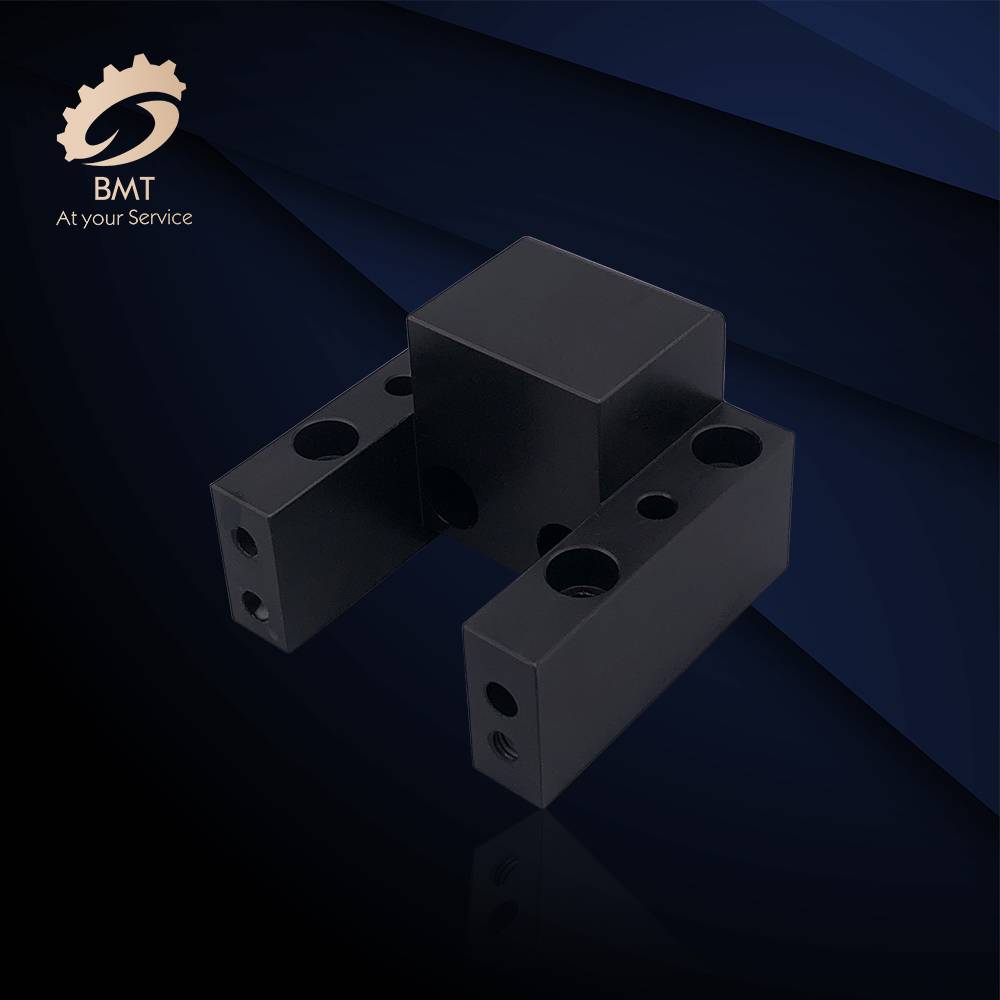

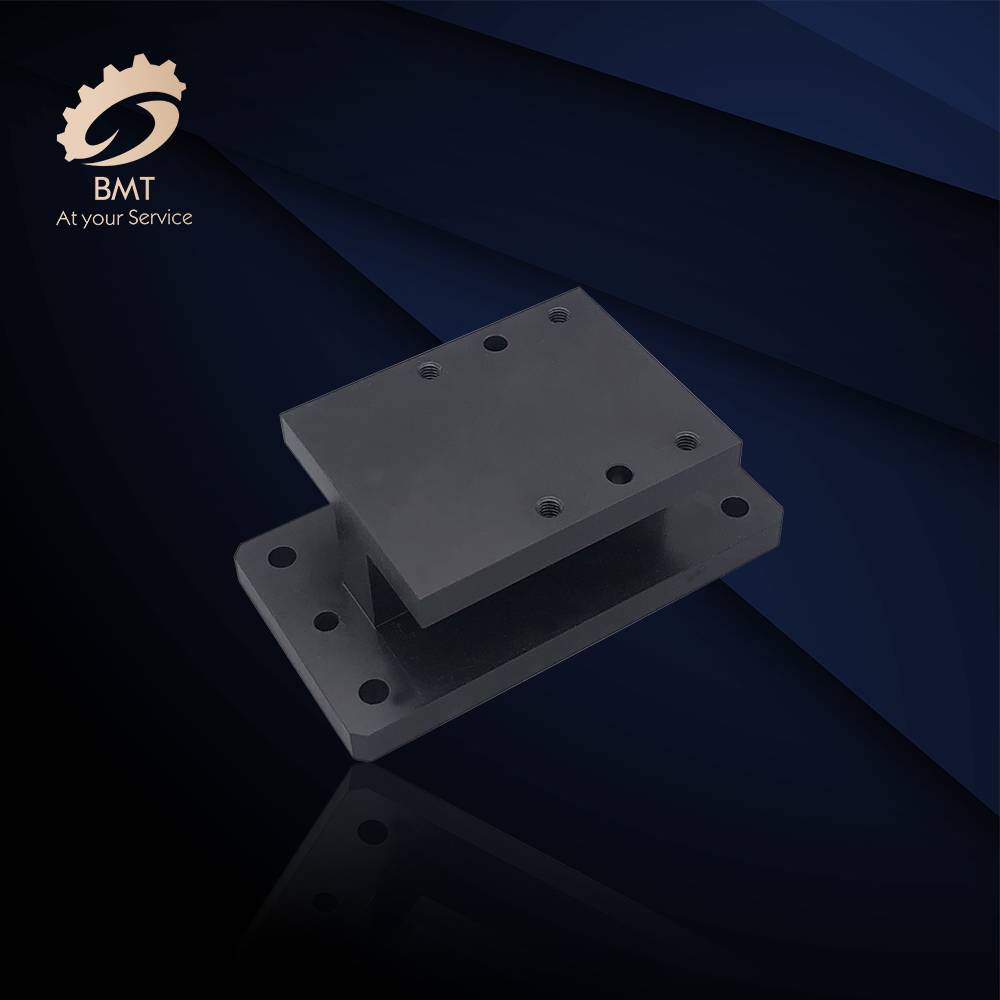

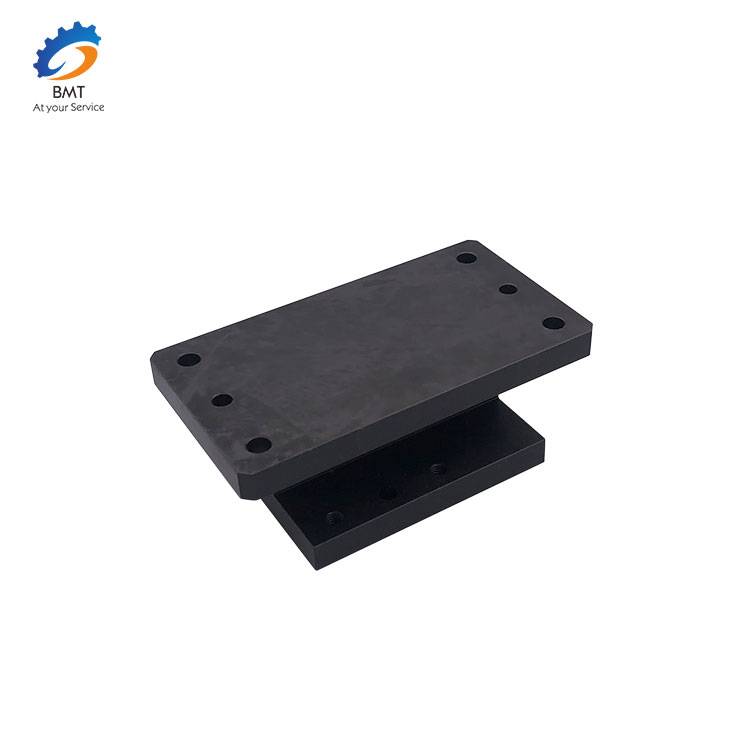

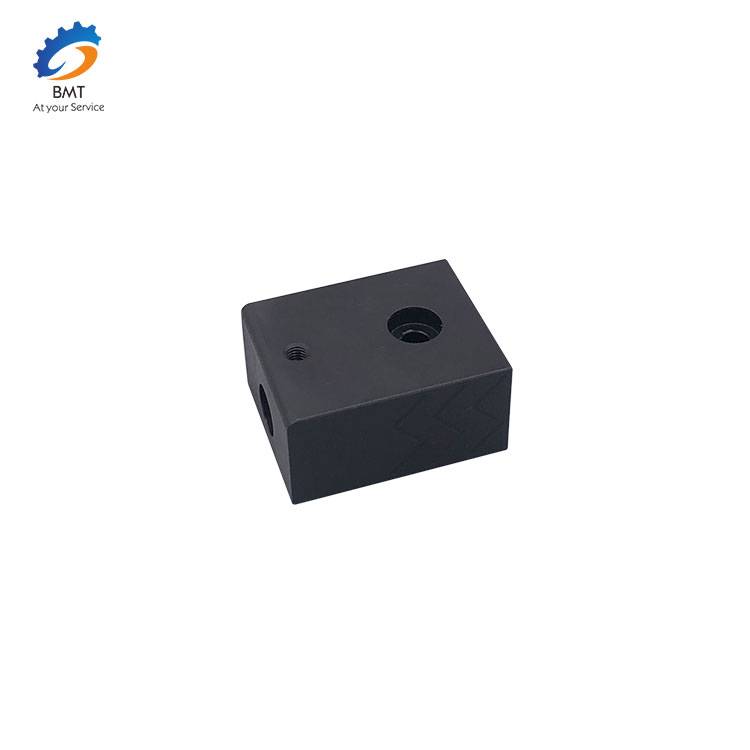

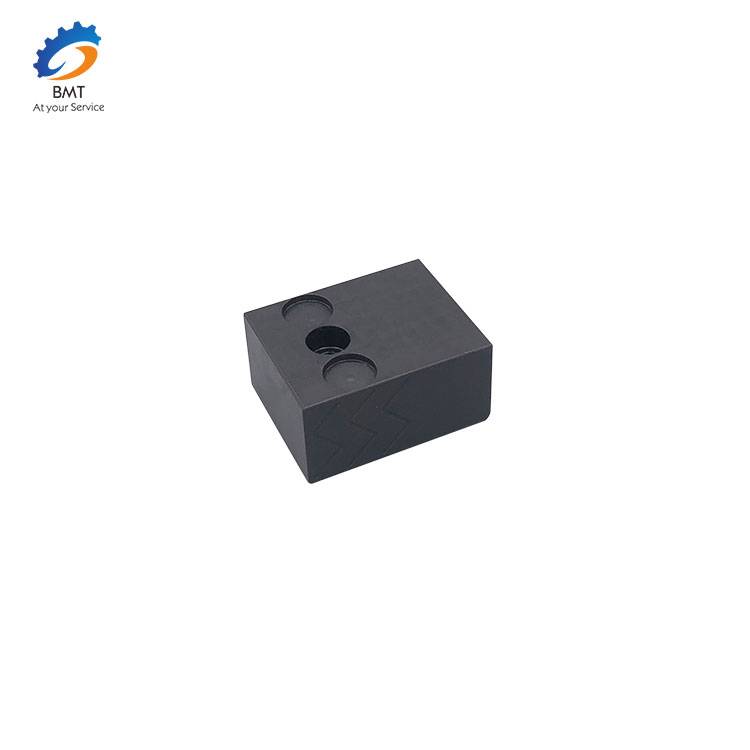

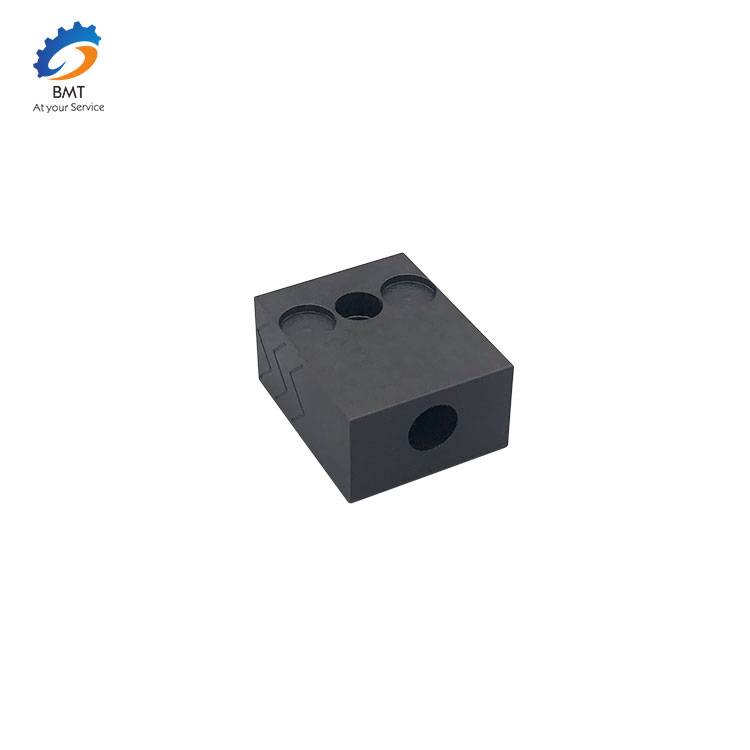

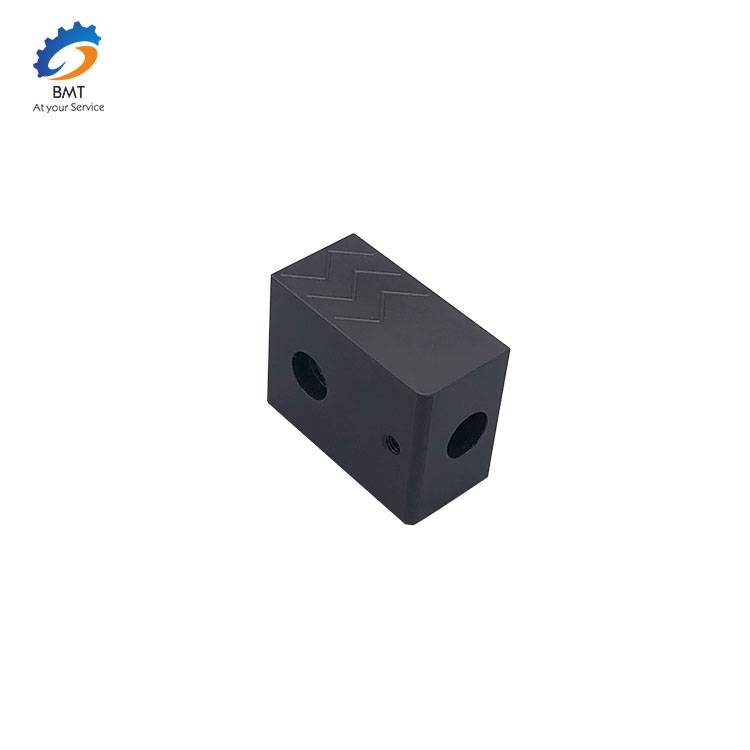

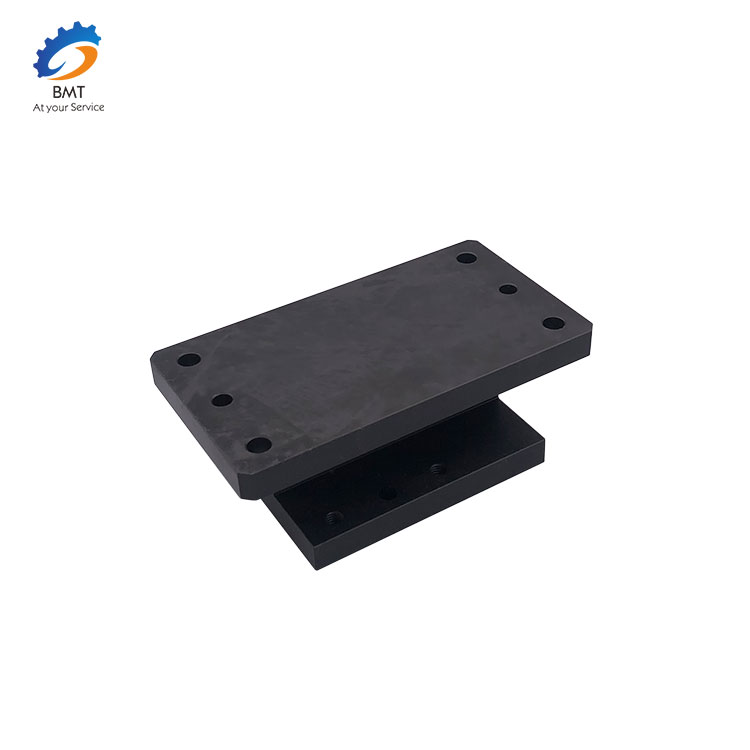

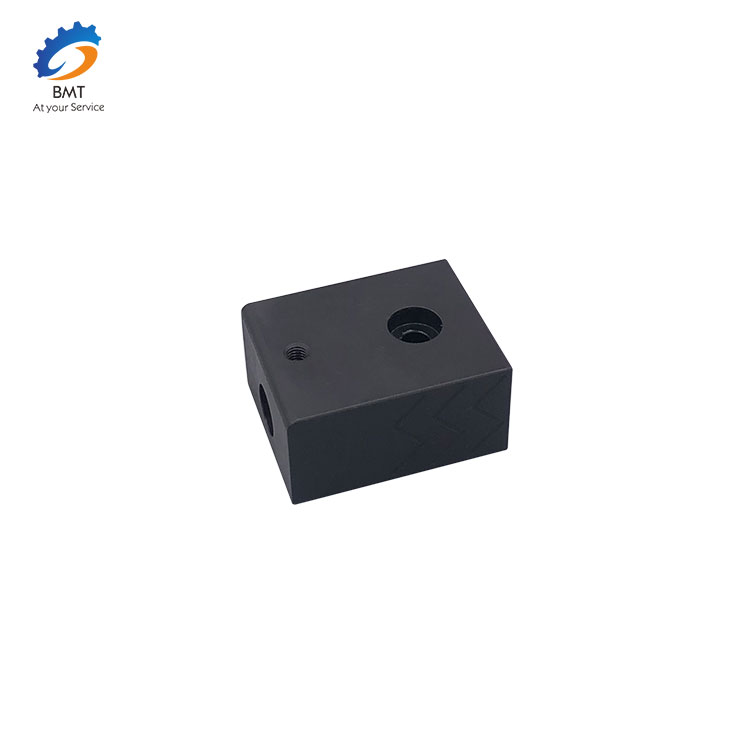

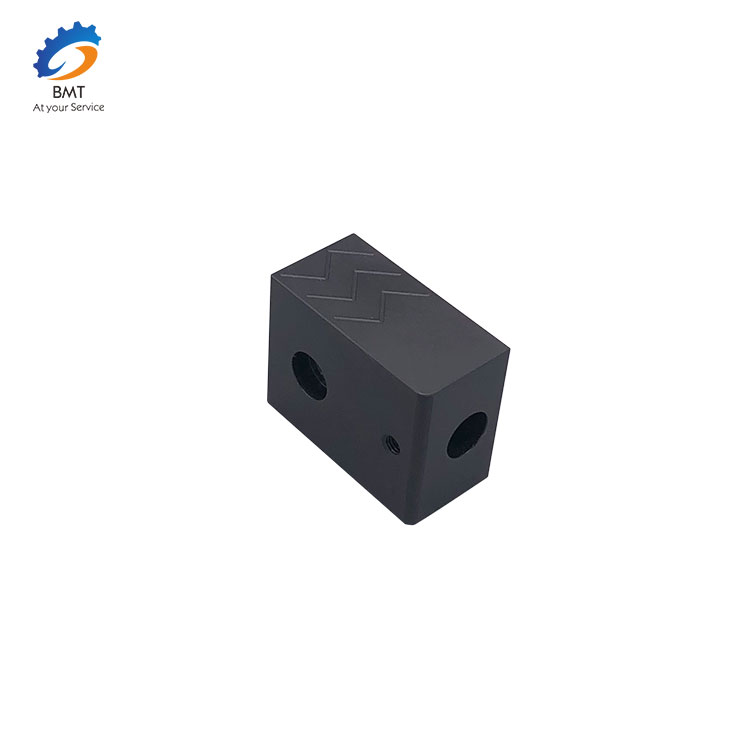

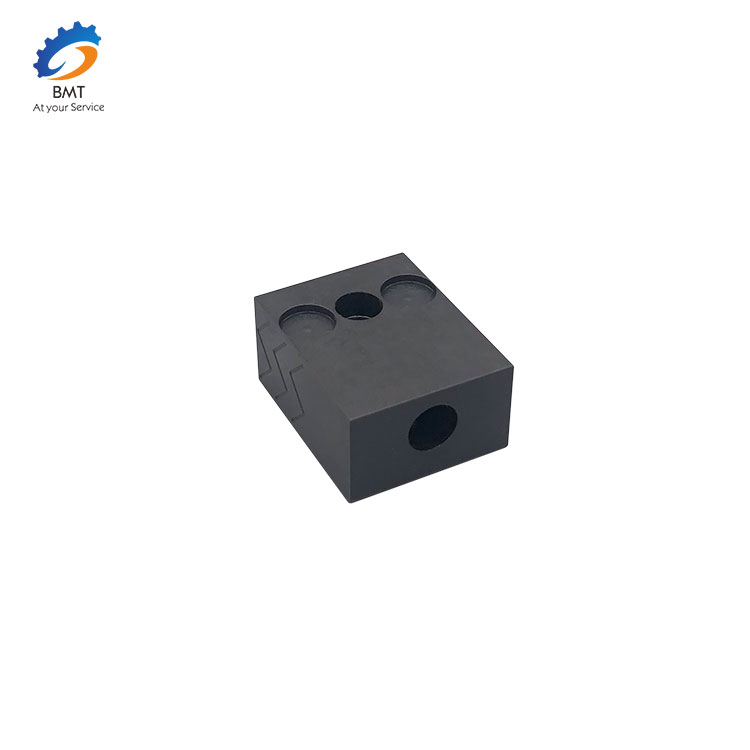

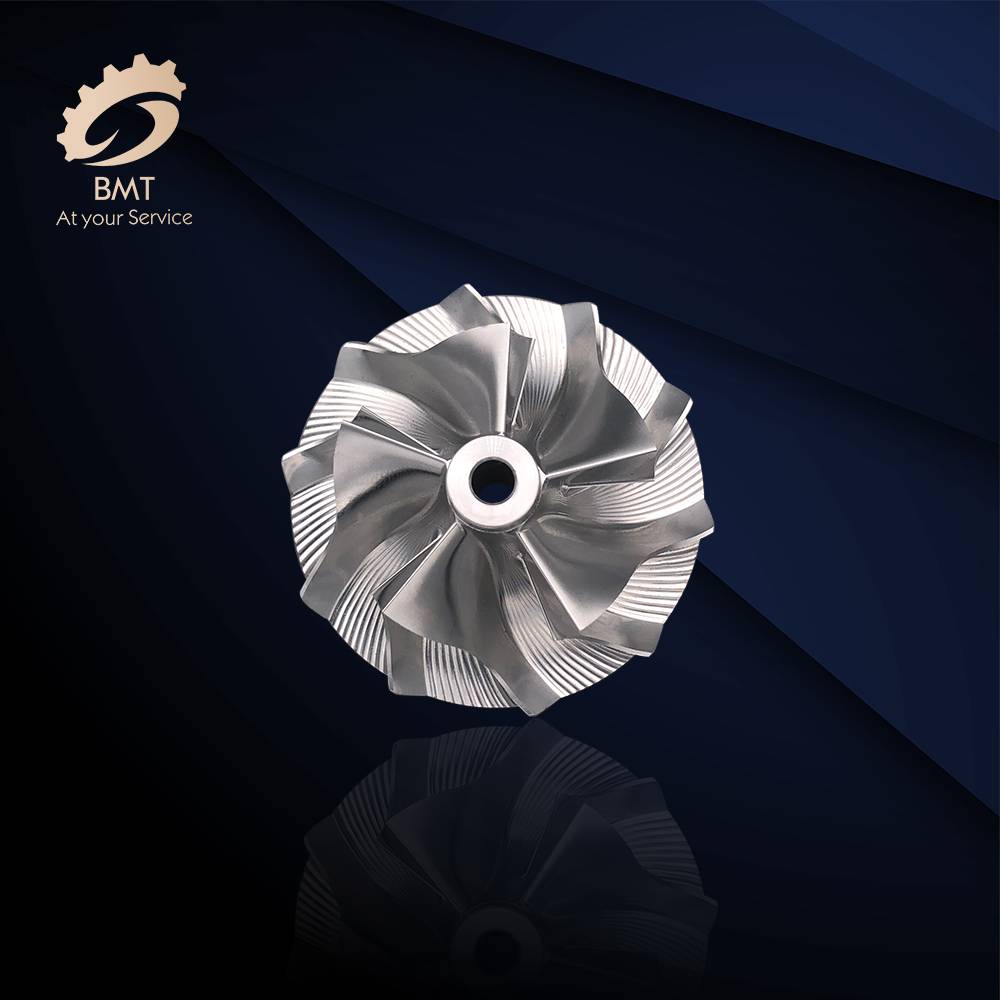

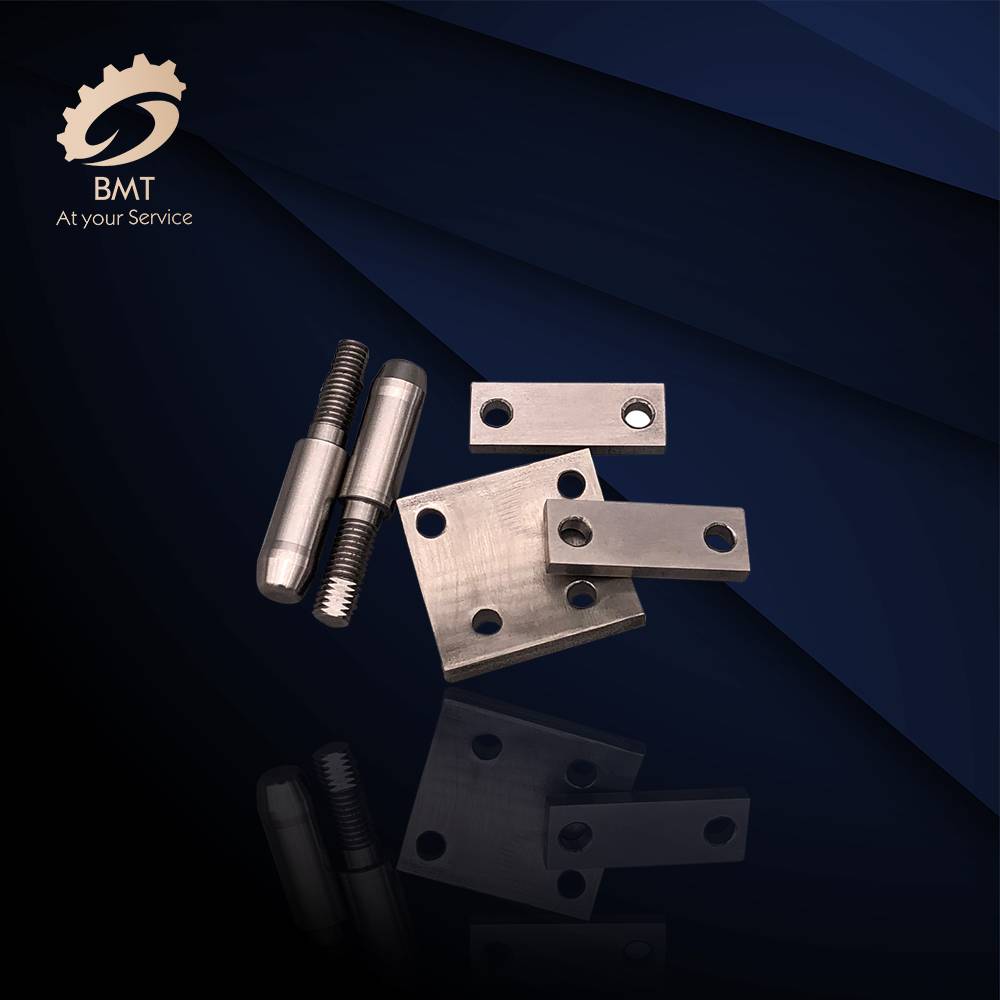

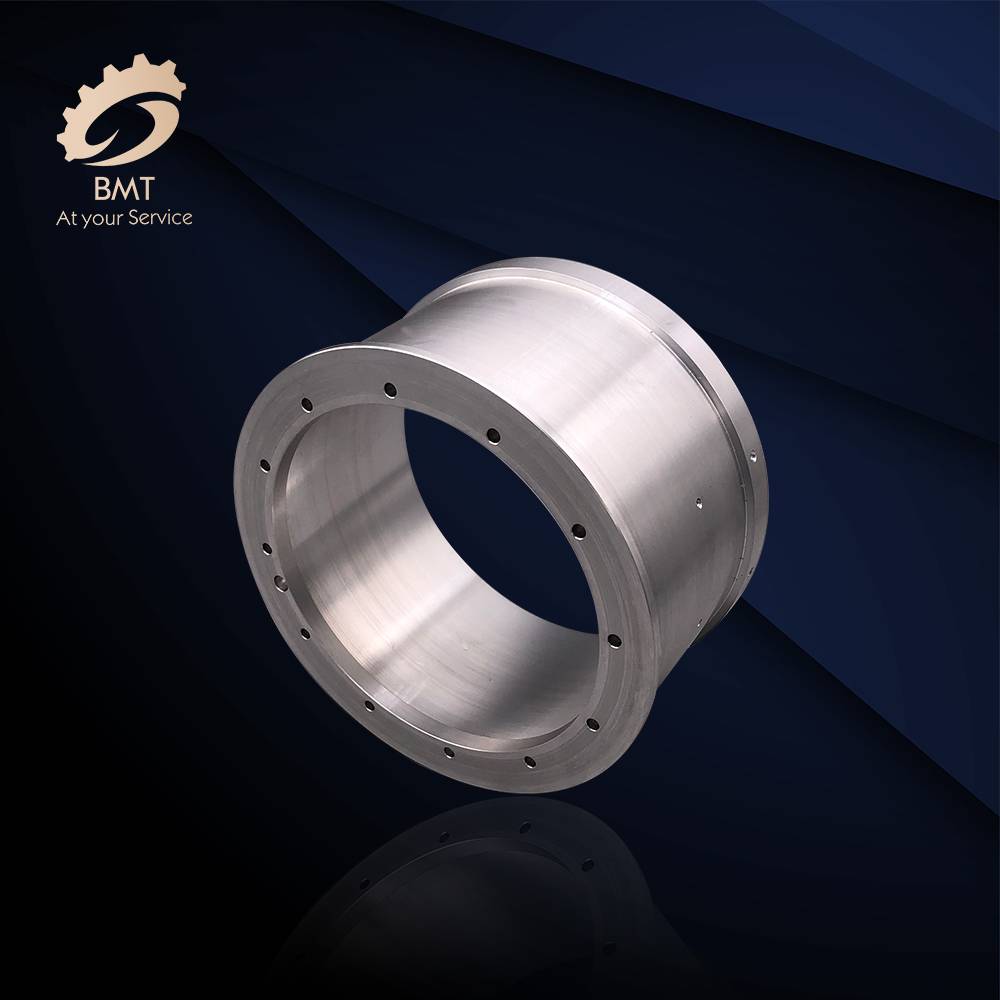

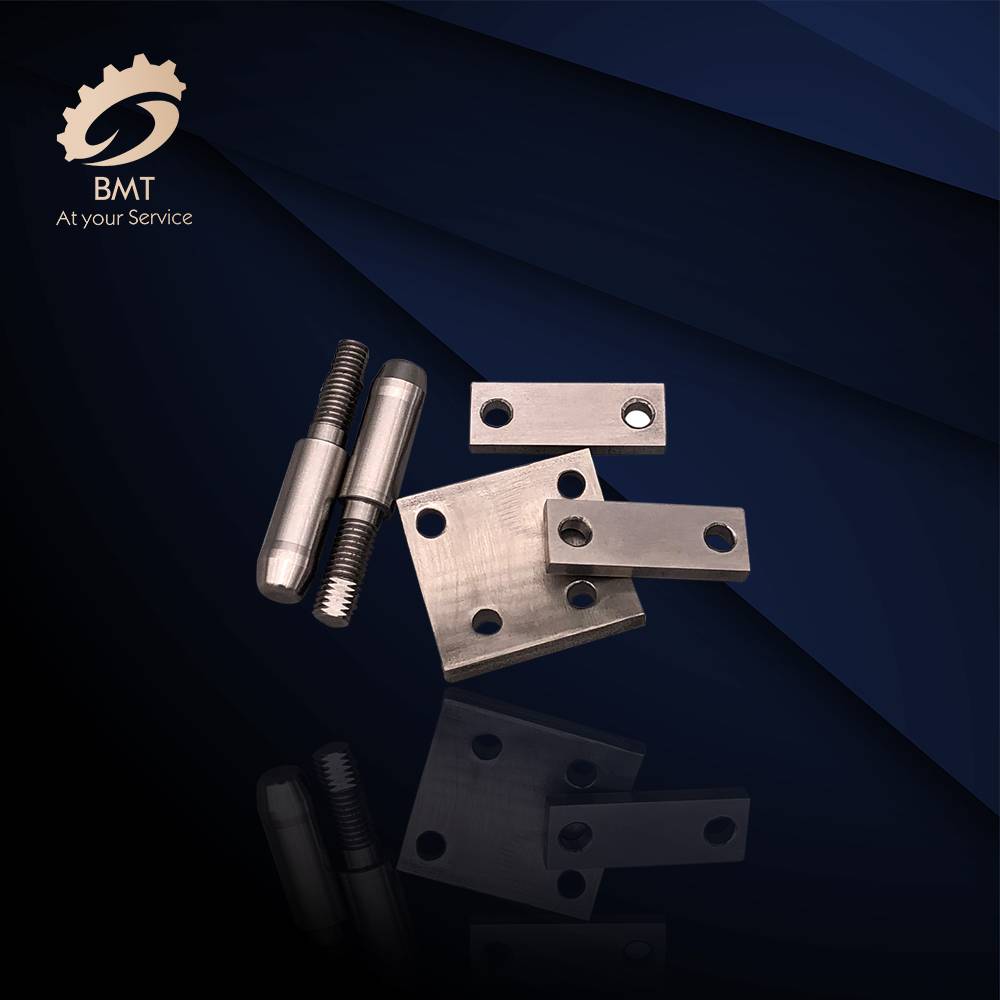

CNC Motor Parts

CNC Machining qhov chaw

CNC Motor Parts

Lub ntsiab Cheebtsam ntawm lub tsheb

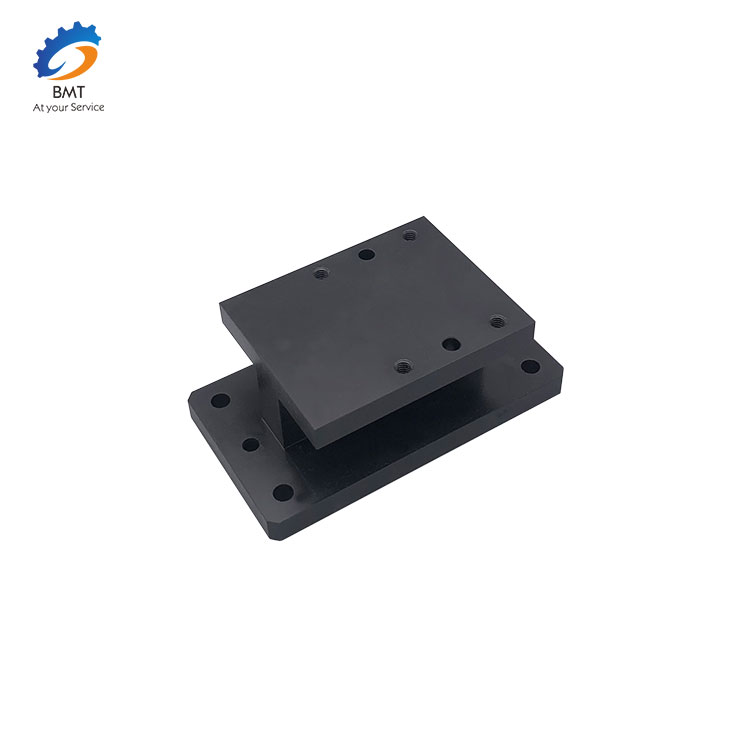

CNC Motor Parts

CNC Machining qhov chaw

CNC Motor Parts

Lub ntsiab Cheebtsam ntawm lub tsheb

Peb tau cog lus los muab cov nqi sib tw, cov khoom tshwj xeeb thiab cov kev daws teeb meem zoo, ib yam nkaus li xa khoom sai rau Tuam Tshoj Dongguan Chaw Tsim Tshuaj High Precision CNC Auto Parts CNC Milling Tshuab Cheebtsam, Saib mus rau yav tom ntej, txoj kev ntev mus, tsis tu ncua siv zog los ua txhua tus neeg ua haujlwm nrog kev txaus siab tag nrho, ib puas npaug ntawm kev ntseeg siab thiab muab peb lub tuam txhab tsim kom muaj ib puag ncig zoo nkauj, cov khoom lag luam siab heev, zoo thawj chav kawm niaj hnub kev lag luam thiab ua haujlwm nyuaj!

Zoo tsim Tuam Tshoj CNC Machined Aluminium Qhov Chaw,CNC Aluminium Part, Raws li ib pab pawg neeg muaj kev paub dhau los peb kuj lees txais kev txiav txim siab thiab ua kom zoo ib yam li koj daim duab lossis cov qauv kev qhia tshwj xeeb thiab cov neeg siv khoom tsim khoom. Lub hom phiaj tseem ceeb ntawm peb lub tuam txhab yog tsim kom muaj lub cim xeeb txaus siab rau txhua tus neeg siv khoom, thiab tsim kom muaj kev sib raug zoo ntawm kev lag luam ntev-yeej. Xaiv peb, peb ib txwm tos koj lub ntsej muag!

Xa koj cov lus rau peb:

-

Hoobkas Promotional Micro CNC Milling Tuam Tshoj Hig ...

-

Factory Outlets Tuam Tshoj Customized CNC Machining Zeb ...

-

Lag luam wholesale nqe Tuam Tshoj Tuam Tshoj High Precision OEM / ...

-

Txhim khu kev qha Supplier Fabrication Hlau Txee / Box ...

-

Tuam Tshoj Professional Tuam Tshoj kev cai CNC Machined ...

-

OEM Hoobkas rau Tuam Tshoj Qhov Zoo Tshaj Plaws Hlau Pre ...