"Raws li kev lag luam hauv tsev thiab nthuav dav kev lag luam tawm txawv teb chaws" yog peb txoj kev vam meej rau 2019 Tseeb Tsim Tuam Tshoj Precision Hlau CNC Machined Parts, Peb zoo siab txais tos cov phooj ywg los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb rau lub hauv paus ntawm kev sib koom ua ke mus sij hawm ntev.

"Raws li kev lag luam hauv tsev thiab nthuav dav kev lag luam txawv teb chaws" yog peb txoj kev vam meej rauTuam Tshoj Customized Machined Parts, Machinery Parts Ua, Ua raws li kev tswj hwm txoj cai ntawm "Kev Tswj Xyuas Ua Siab Zoo, Yeej los ntawm Kev Ua Zoo", peb sim peb qhov zoo tshaj plaws los muab cov khoom zoo thiab cov kev daws teeb meem thiab kev pabcuam rau peb cov neeg siv khoom.Peb tos ntsoov kom ua tiav ua ke nrog cov neeg siv khoom hauv tsev thiab thoob ntiaj teb.

Technology Characterizes Mechanical Precision Machining

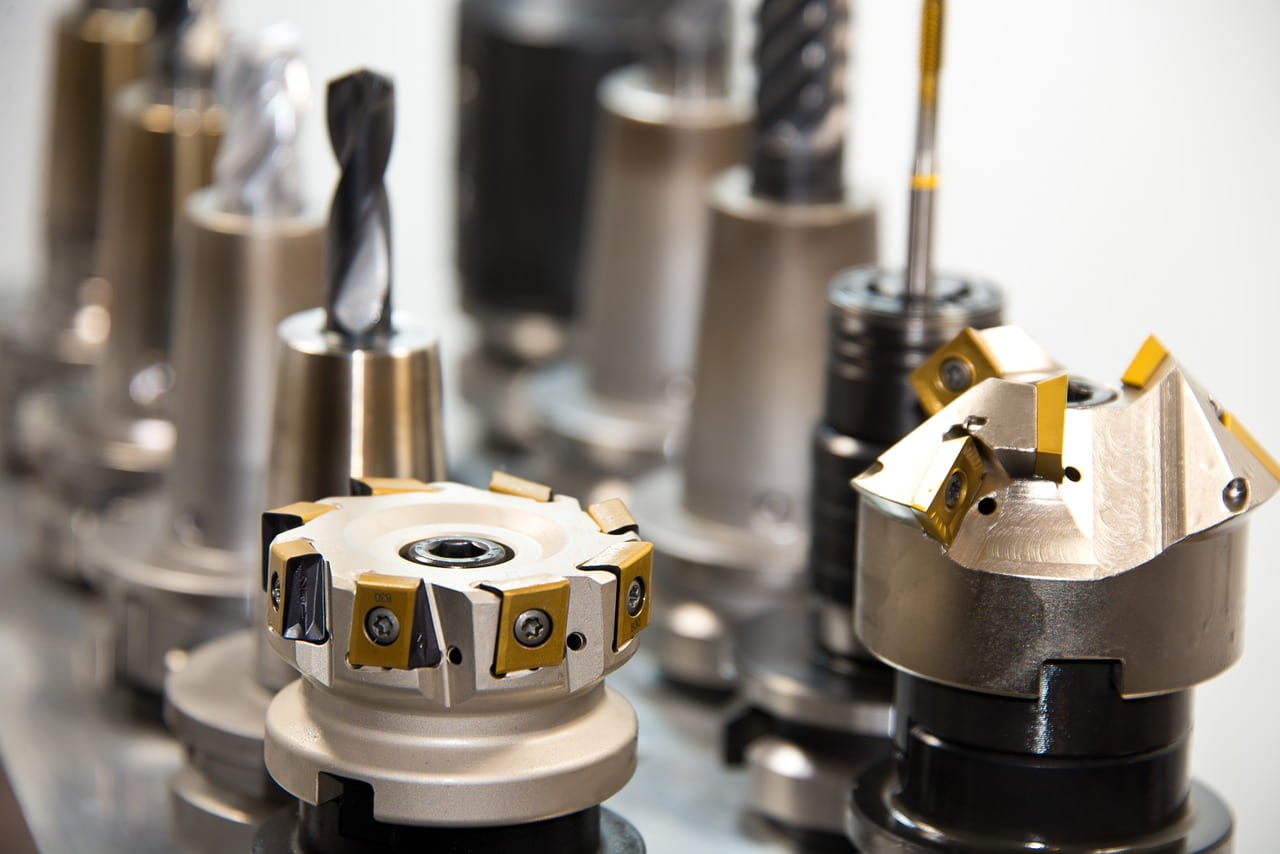

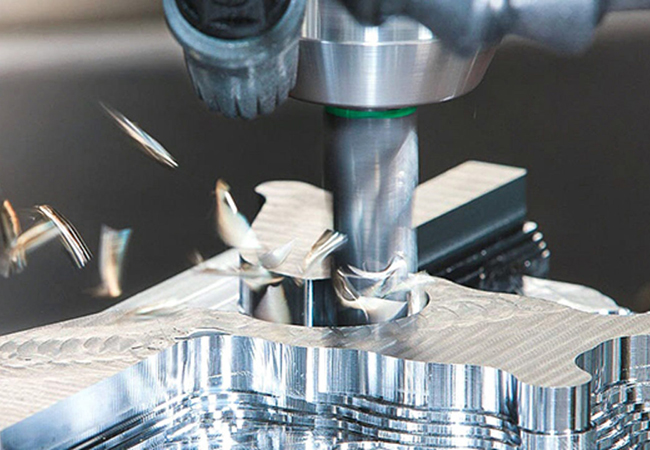

(1) Precision Txiav Technology

Feem ntau, precision txiav tshuab yog ncaj qha siv txoj kev txiav kom tau siab precision, yog li nws muaj cov kev cai zoo dua ntawm cov khoom txiav.Piv txwv li, qhov yuav tsum tau ntawm high precision nto roughness yuav tsum tau ua raws li.Tab sis nws yog ib qho tsim nyog sau cia tias yog tias koj xav siv txoj kev txiav kom tau txais qhov siab tshaj plaws thiab qib siab ntawm qhov roughness, koj yuav tsum tau ua kom nquag plias los ntawm kev cuam tshuam ntawm cov cuab yeej siv tshuab, cov cuab yeej, workpiece thiab lwm yam.Piv txwv li, txhawm rau txhawm rau txhim kho qhov tseeb thiab qhov tseeb ntawm cov cuab yeej siv tshuab, nws yog ib qho tsim nyog yuav tsum xaiv cov cuab yeej siv lub tshuab nrog kev nruj nruj, me me thermal deformation, thiab kev co ua haujlwm zoo.

(2) Ultra-Precision Sib Tsoo Technology

Rau machining, aiming ntawm ncav cuag 1-2mm nto roughness, thiab siv atomic qib sib tsoo polishing silicon wafer.Kev sib tsoo yav dhau los, abrasive machining, polishing thiab lwm yam kev ua haujlwm tsis tuaj yeem ua tau raws li qhov xav tau ntawm txoj haujlwm no.Yog li ntawd, cov ntsiab cai tshiab thiab cov txheej txheem yuav tsum tau soj ntsuam thiab kawm kom tob.Nws yog nyob rau hauv keeb kwm yav dhau no uas ultra-precision sib tsoo tshuab tshwm sim ntawm lub sijhawm keeb kwm thiab ua lub luag haujlwm tseem ceeb hauv kev siv tshuab precision tshuab.

(1) Qhov cuam tshuam ntawm Niaj hnub nimno Mechanical Manufacturing Technology thiab Mechanical Precision Machining Technology.

Nyob rau hauv cov nqe lus ntawm kev tsim technology, niaj hnub mechanical manufacturing technology thiab precision processing technology yog koom nyob rau hauv ntau yam ntawm mechanical kev lag luam, xws li manufacturing engineering, khoom tsim thiab kev loj hlob, khoom txheej txheem tsim, ua thiab tsim, khoom muag, thiab lwm yam. Thaum muaj teeb meem tshwm sim. Hauv cov kev lag luam no, lawv yuav cuam tshuam ncaj qha rau tag nrho cov saw hlau engineering.Yog li ntawd, peb yuav tsum muab qhov tseem ceeb rau kev sib raug zoo ntawm kev lag luam niaj hnub machinery manufacturing kev lag luam thiab precision machining technology, thiaj li los txhawb txoj kev vam meej thiab kev loj hlob ntawm mechanical technology.Yog li ntawd, nyob rau hauv kev xyaum, niaj hnub mechanical technology thiab precision machining technology yuav tsum tau tag nrho ua ke los txhawb txhua yam kev vam meej thiab ua kom tiav kev loj hlob sai thiab kev vam meej ntawm technology.

(2) Systematic ntawm niaj hnub Mechanical Manufacturing Technology thiab Mechanical Precision Machining Technology.

Niaj hnub nimno machinery manufacturing ntau lawm yog complex system engineering nyob rau hauv kev siv ntawm niaj hnub machinery manufacturing technology thiab precision ua technology, xws li cov khoom tsim, ntau lawm thiab muag khoom, uas yuav koom nrog computer cov ntaub ntawv technology, niaj hnub sensing technology, ntau lawm automation technology thiab ntau lwm yam technologies.Tsis tas li ntawd, tej zaum yuav tsum tau siv cov ntaub ntawv tshiab, cov kev tswj xyuas tshiab, thiab lwm yam. Yog li ntawd, kev hais lus tag nrho, kev tsim tshuab ntawm kev lag luam tshuab tsis tuaj yeem sib cais los ntawm kev siv dav dav ntawm ntau yam kev siv tshuab thev naus laus zis niaj hnub, uas yuav tsum tau ua kom muaj kev lag luam niaj hnub. machinery manufacturing technology thiab precision processing technology kom muaj ntau dua qhov system.

(3) Lub Ntiaj Teb Kev Lag Luam ntawm Niaj Hnub Mechanical Manufacturing Technology thiab Precision Machining Technology.

Tam sim no, nrog rau txoj kev loj hlob ntawm kev lag luam thoob ntiaj teb, ntau qhov kev lag luam ntawm peb lub teb chaws tau maj mam paub txog kev koom ua ke nrog cov qauv thoob ntiaj teb.Kev lag luam thoob ntiaj teb kev lag luam tau tsim cov qauv tseem ceeb ntawm kev cuam tshuam kev loj hlob tam sim no.Nyob rau tib lub sijhawm, nyob rau hauv keeb kwm ntawm kev lag luam thoob ntiaj teb kev lag luam, kev sib tw ua lag luam intensifies, machinery manufacturing kev lag luam nyob rau hauv peb lub teb chaws nyob rau hauv thiaj li yuav txhawb kev sib tw ntawm cov lag luam nyob rau hauv lub domestic thiab thoob ntiaj teb kev lag luam, peb yuav tsum ua raws li lub sij hawm txoj kev loj hlob, nquag qhia thoob ntiaj teb advanced mechanical. manufacturing technology thiab precision machining thev naus laus zis, nce peev hauv kev lag luam hauv kev tshawb fawb cultivate high-level technical neeg ua haujlwm, kev tshawb fawb thiab kev tsim kho raws li qhov tseeb ntawm cov tuam txhab machinery manufacturing technology thiab precision machining technology, thiaj li paub txog kev noj qab haus huv thiab kev loj hlob ntawm kev tsim khoom. cov lag luam.

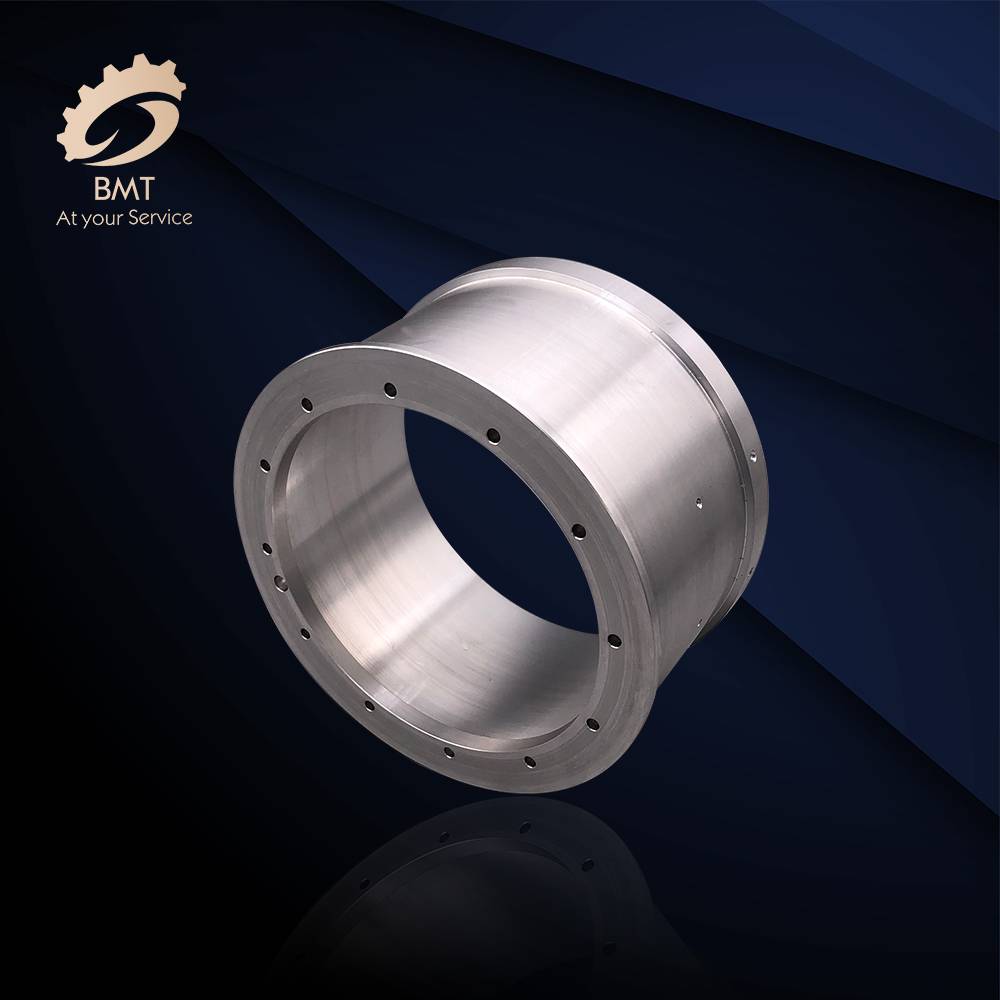

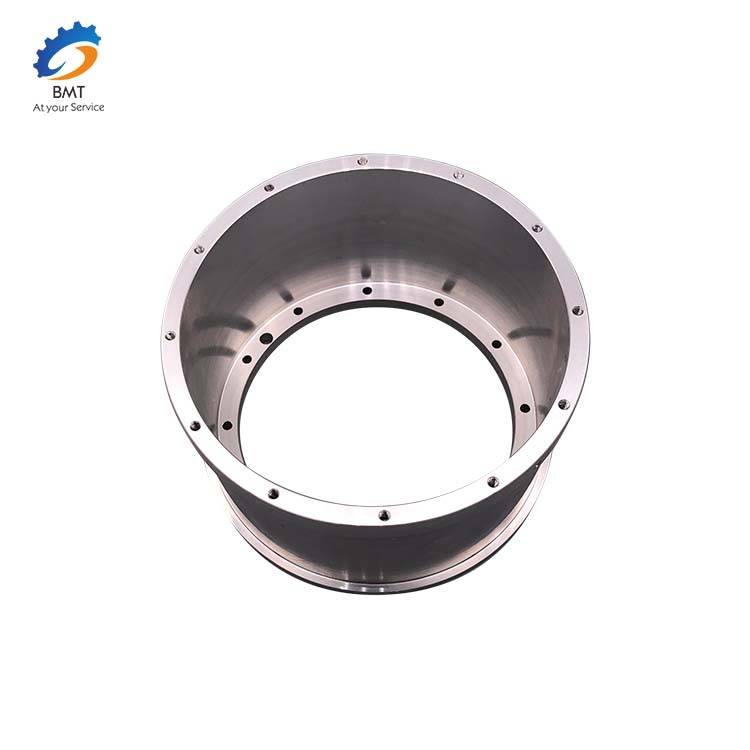

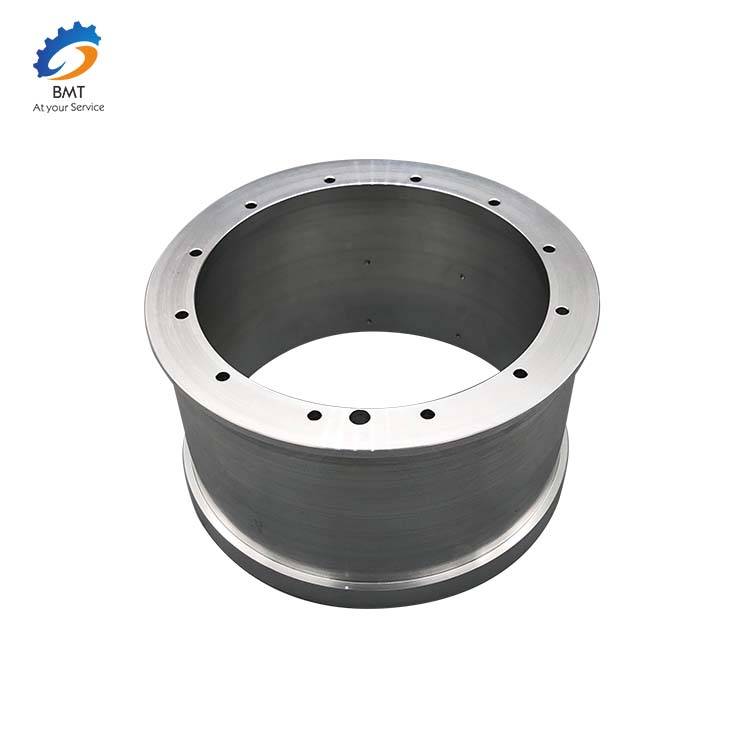

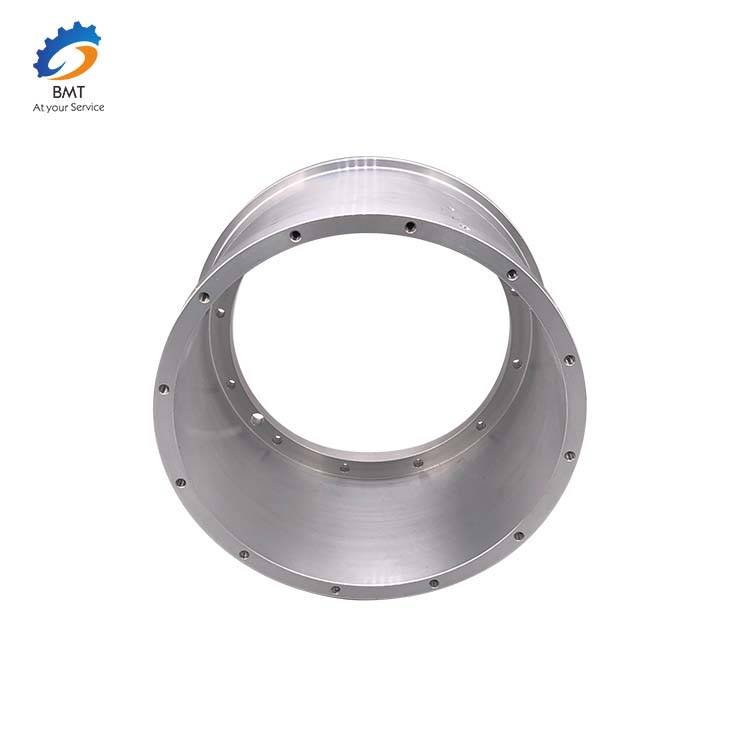

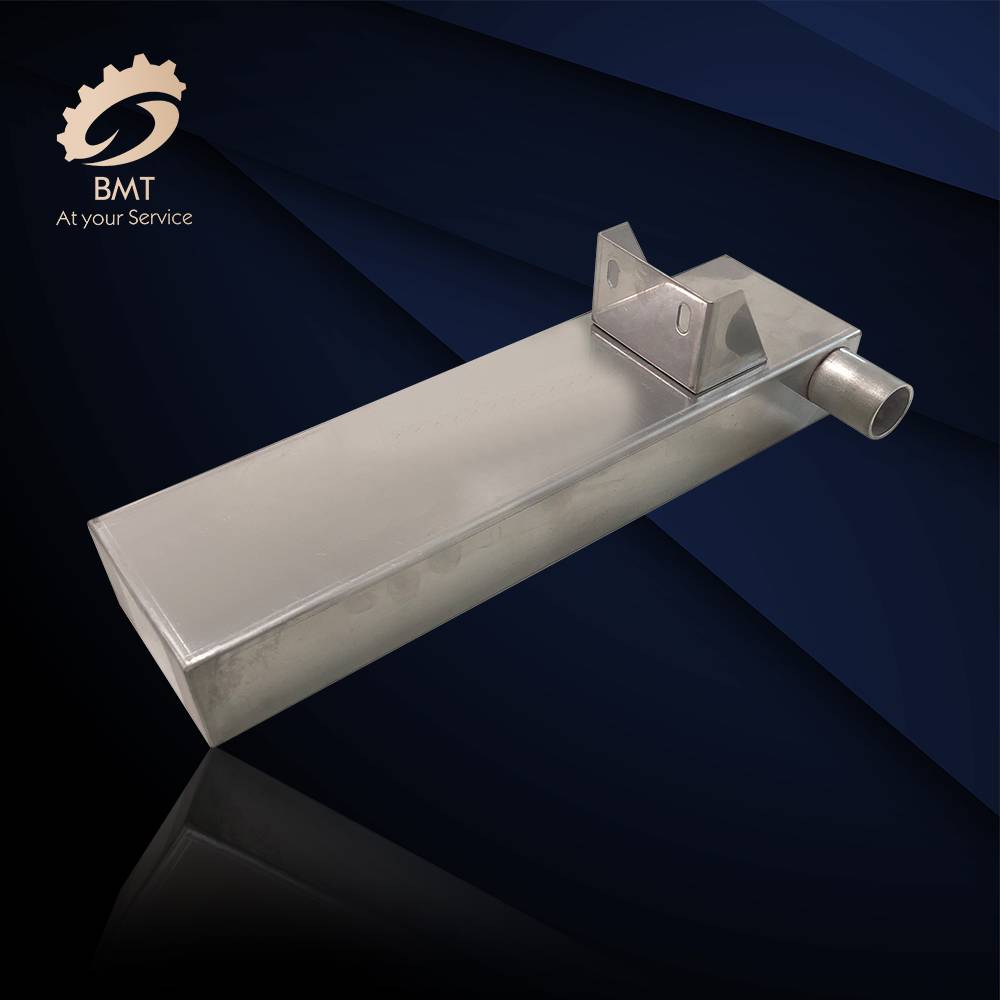

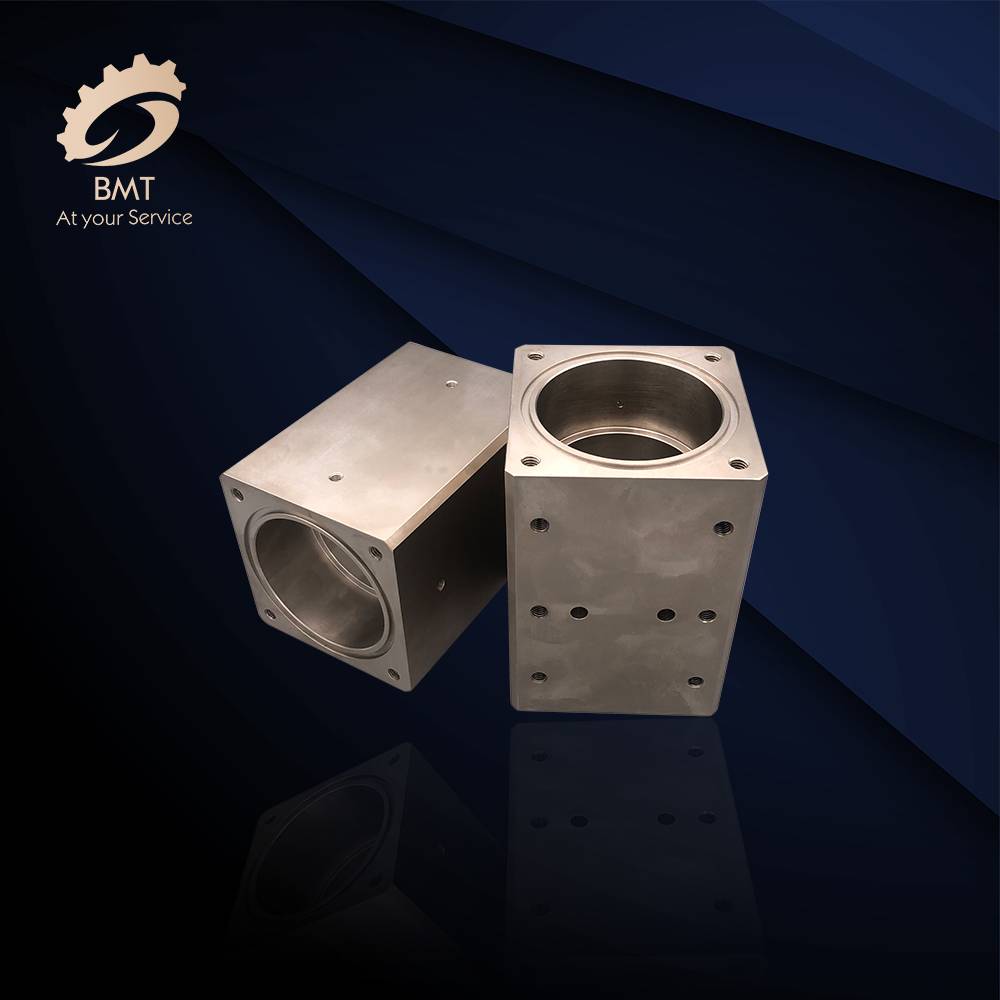

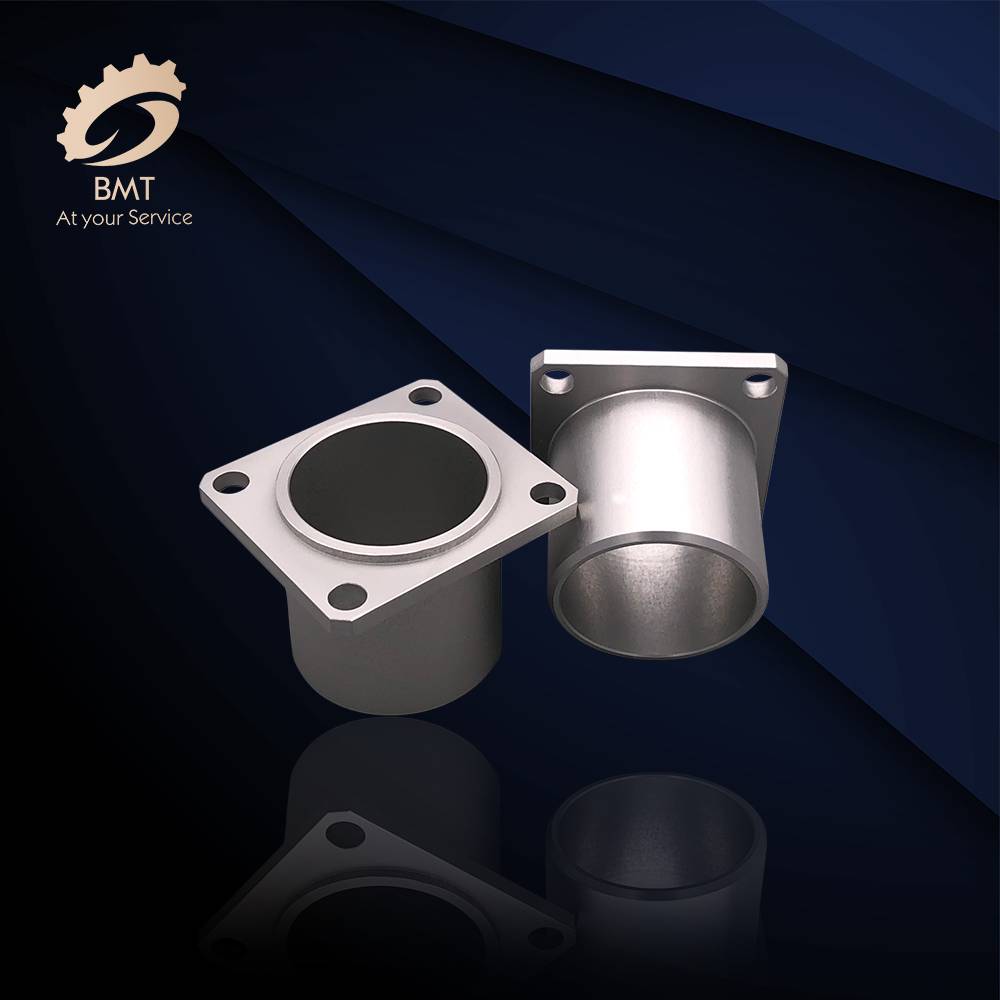

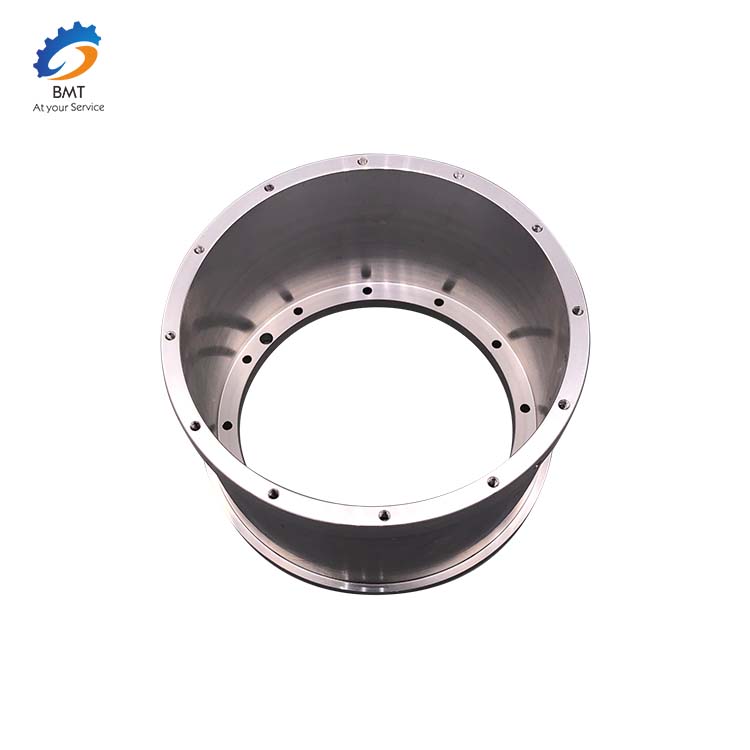

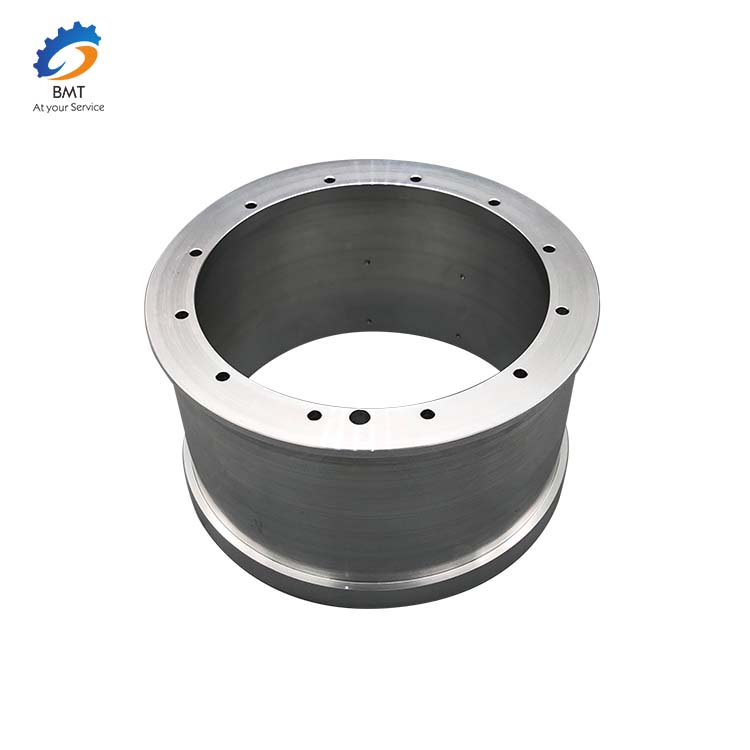

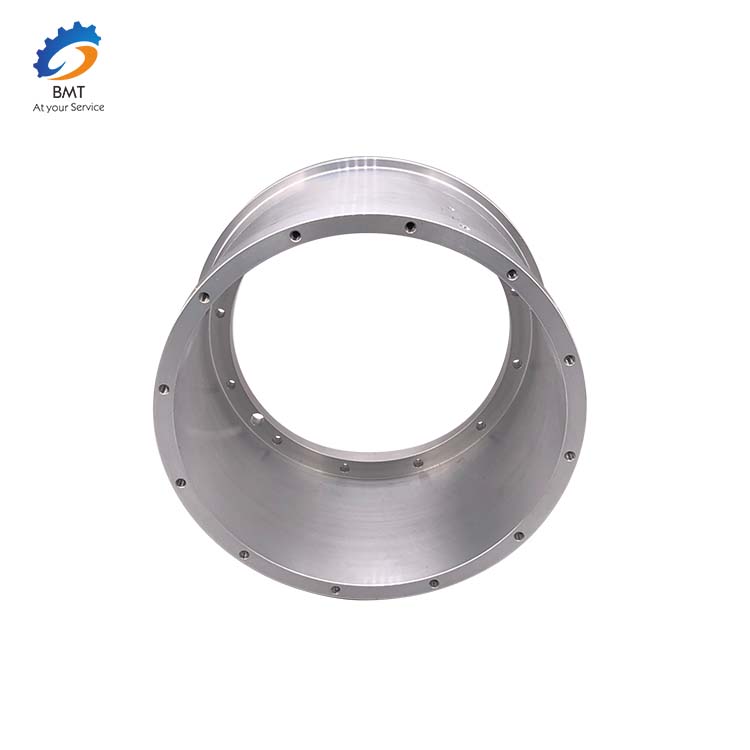

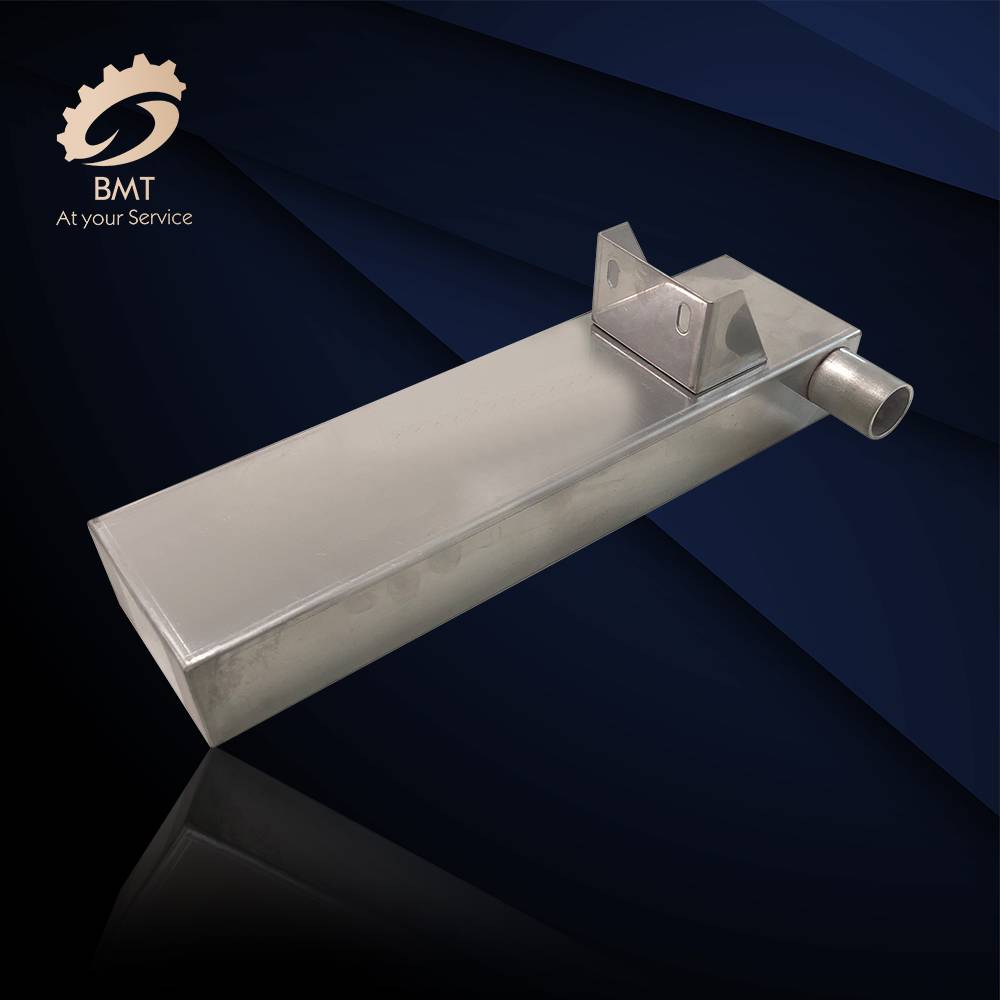

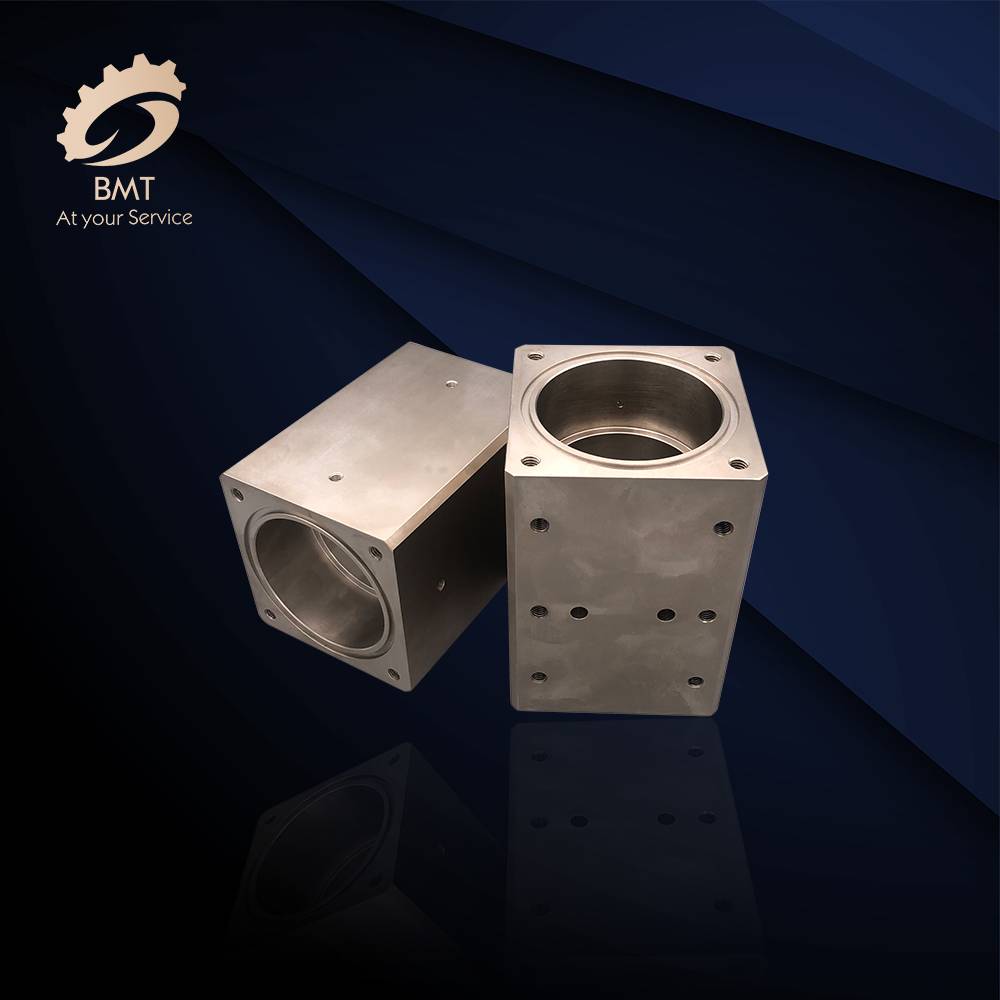

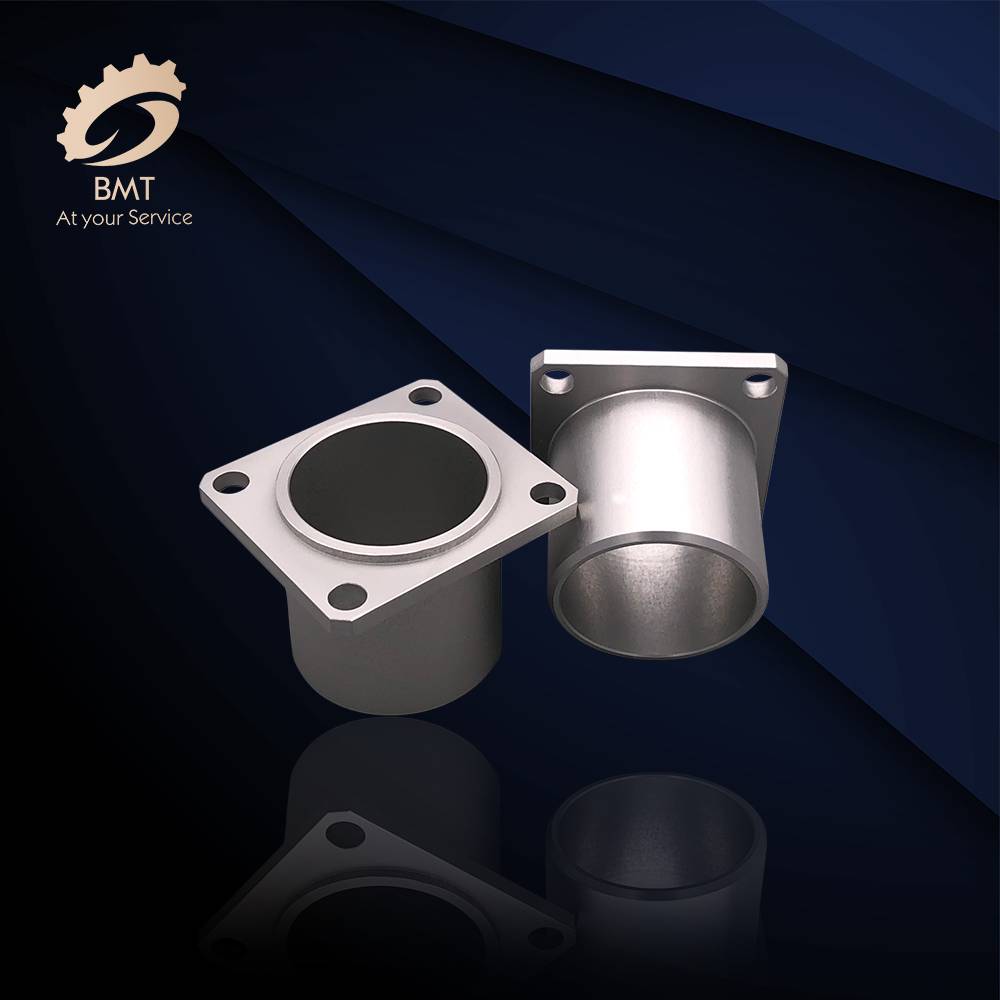

Product Description

Precision Machining qhov chaw

Precision Machining qhov chaw

Ua ntej CNC kev tsim khoom, kev tsim khoom tau ua tiav nkaus xwb kuv phau ntawv tshuab ua haujlwm thiab saib xyuas tus neeg txhua lub sijhawm.Tsis tsuas yog nws ua rau tsawg dua cov khoom tau txais kev tsim khoom tab sis nws kuj ua rau muaj qhov yuam kev loj hauv cov khoom kawg.Kev koom ua ke cov khoos phis tawj rau hauv kev tsim khoom tau nce qhov nrawm thiab raug ntawm cov cuab yeej tsim khoom los ntawm txhiab folds.Txhua yam koj yuav tsum tau ua yog ntxig cov lus txib yooj yim rau hauv software thiab nws yuav ua cov khoom siv raw los ntawm cov tshuab nrog qhov zoo tshaj plaws.Niaj hnub no, tag nrho cov kev cai machining cov kev pab cuam muaj CNC raws li lawv lub ntsiab tseem ceeb.Los ntawm milling, tshuab dhos, precision txiav, thiab tig, txhua yam kev tsim khoom yog ua los ntawm CNC machining kom ua rau kev lag luam loj tshaj plaws.

Hauv xyoo tom ntej, huab xam, thiab kev muaj tiag virtual yuav ua lub luag haujlwm tseem ceeb hauv CNC manufacturing.Txhua lub khw muag khoom CNC tshuab saum toj kawg nkaus tau ua ntau tshaj plaws hauv internet kom cov txheej txheem tsim ua haujlwm 24/7.CNC tshuab tuaj yeem ua haujlwm nyob deb yam tsis muaj kev cuam tshuam nrog tib neeg ua ntej, txo qis kev pheej hmoo ntawm chaw ua haujlwm.Virtual thiab augmented kev muaj tiag yuav ua rau kev tsim khoom ntau dua.Cov chaw muab kev pabcuam machining tuaj yeem hloov kho qhov me me tshaj plaws hauv cov khoom tsim los ua kom nws siv tau ntau tshaj plaws.Lwm qhov tseem ceeb tshaj plaws software hloov tshiab suav nrog kov npo mechanism thiab virtual simulations nyob rau hauv ib puag ncig tswj.

Xa koj cov lus rau peb:

-

OEM Tuam Tshoj Tuam Tshoj Dub Anodized Enclosure Custom...

-

100% Thawj Hoobkas Tuam Tshoj Customized Precisio ...

-

Kev soj ntsuam zoo rau Tuam Tshoj Customized Precisi ...

-

Sab saum toj Suppliers Tuam Tshoj Custom Precision CNC Proces ...

-

2019 High quality Tuam Tshoj Forged Aviation Aluminu ...

-

Tuam Tshoj Brass/Steel/Aluminium/Metal Parts, Custom...