Kev faib tawm ntawm cov tshuab sib tsoo

Nrog rau qhov nce ntawm tus naj npawb ntawmhigh-precisionthiab siab hardness mechanical qhov chaw, nrog rau kev loj hlob ntawm precision casting thiab precision forging tshuab, kev ua tau zoo, ntau yam thiab cov khoom siv ntawm cov tshuab sib tsoo yog tas li txhim kho thiab loj hlob.

(1) Cylindrical grinder:Nws yog ib qho yooj yim series ntawm hom zoo tib yam, feem ntau yog siv rau kev sib tsoo cylindrical thiab conical sab nraud.

(2) Internal grinder:Nws yog ib hom puag hom series, feem ntau yog siv rau kev sib tsoo cylindrical thiab conical sab hauv.

(3) Coordinate grinder:internal grinder nrog cov kev sib koom tes ua haujlwm zoo.

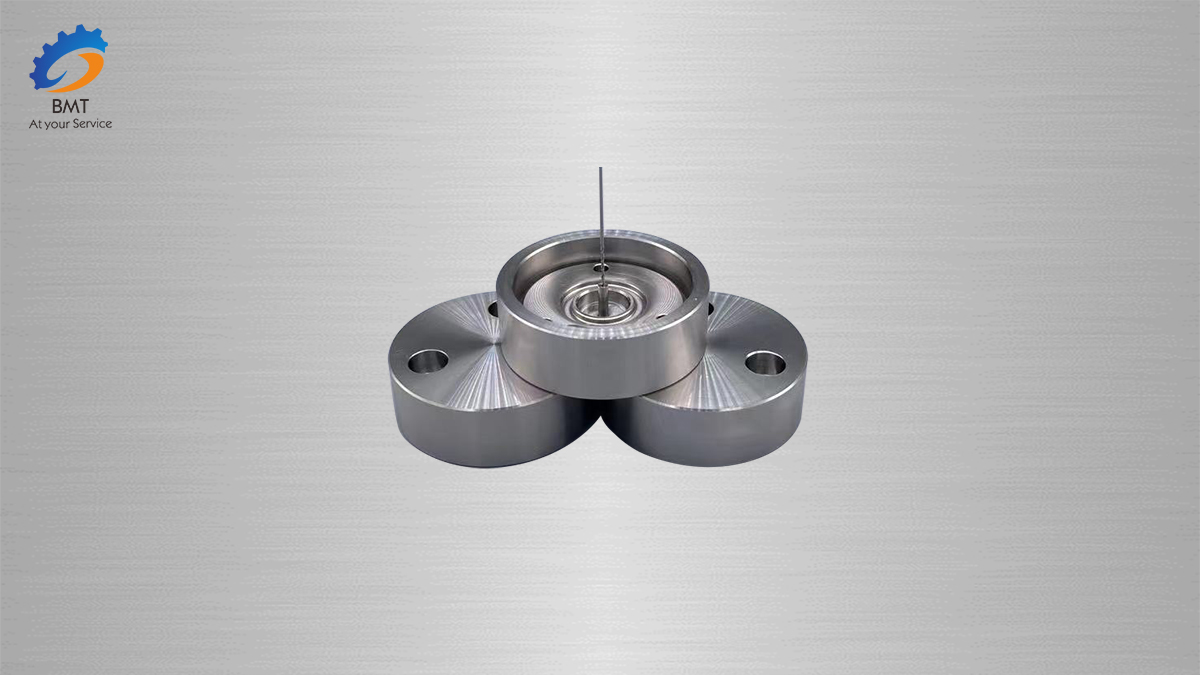

(4) Centerless grinder:Lub workpiece yog clamped centerless, feem ntau txhawb nruab nrab ntawm lub log qhia thiab lub bracket, thiab lub log qhia tsav lub workpiece tig.Nws yog tsuas yog siv rau kev sib tsoo cylindrical nto.

(5) Nto grinder: feem ntau yog siv rau kev sib tsoo nto ntawm workpiece.

(6) Abrasive siv grinder:Lub grinder uas siv ceev ceev abrasive siv rau kev sib tsoo.

(7) Honing tshuab:Nws yog siv rau honing ntau qhov chaw ntawm workpieces.

(8) Grinder:Nws yog siv los zom rau sab hauv thiab sab nrauv ntawm lub dav hlau workpiece lossis lub tog raj kheej.

(9) Qhia rail grinder:feem ntau yog siv rau kev sib tsoo cov lus qhia rail nto ntawm lub tshuab cuab yeej.

(10) Cov cuab yeej grinder:Lub grinder siv rau kev sib tsoo cov cuab yeej.

(11) Ntau lub hom phiaj sib tsoo tshuab:Nws yog siv rausib tsoo cylindricalthiab conical sab hauv thiab sab nrauv los yog dav hlau, thiab tuaj yeem siv cov khoom siv servo thiab cov khoom siv los zom ntau yam ntawm cov khoom ua haujlwm.

(12) Tshwj xeeb sib tsoo tshuab:ib lub tshuab tshwj xeeb siv rau kev sib tsoo qee yam ntawm qhov chaw.Raws li nws cov khoom ua, nws tuaj yeem muab faib ua spline ncej grinder, crankshaft grinder, cam grinder, iav grinder, xov grinder, nkhaus grinder, thiab lwm yam.

Kev Tiv Thaiv Kev Nyab Xeeb

Sib tsooyog dav siv thiab yog ib txoj hauv kev tseem ceeb rau precision machining ntawm tshuab qhov chaw.Txawm li cas los xij, vim qhov kev kub ceev ntawm lub tshuab sib tsoo ntawm lub tshuab sib tsoo, lub log sib tsoo yog tawv, nkig, thiab tsis tuaj yeem tiv taus qhov hnyav.Qee lub sij hawm ua haujlwm tsis raug yuav ua rau muaj qhov tshwm sim loj heev yog tias lub log sib tsoo tawg.Yog li ntawd, kev nyab xeeb kev ua haujlwm ntawm kev sib tsoo yog qhov tseem ceeb tshwj xeeb.Txhim khu kev ruaj ntseg cov cuab yeej tiv thaiv yuav tsum tau txais, thiab kev ua haujlwm yuav tsum tau ua kom muaj zog kom ntseeg tau tias tsis muaj kev pheej hmoo.Tsis tas li ntawd, cov xuab zeb zoo thiab cov chips hlau txaws los ntawm lub workpiece ntawm kev sib tsoo lub log thaum sib tsoo yuav ua mob rau cov neeg ua haujlwm qhov muag.Yog tias cov neeg ua haujlwm nqus cov plua plav no ntau, nws yuav tsim kev puas tsuaj rau lawv txoj kev noj qab haus huv, thiab kev tiv thaiv tsim nyog yuav tsum tau ua.Cov teeb meem kev nyab xeeb hauv qab no yuav tsum tau them sai sai rau thaum sib tsoo.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining qhov chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Pipes / Tubes