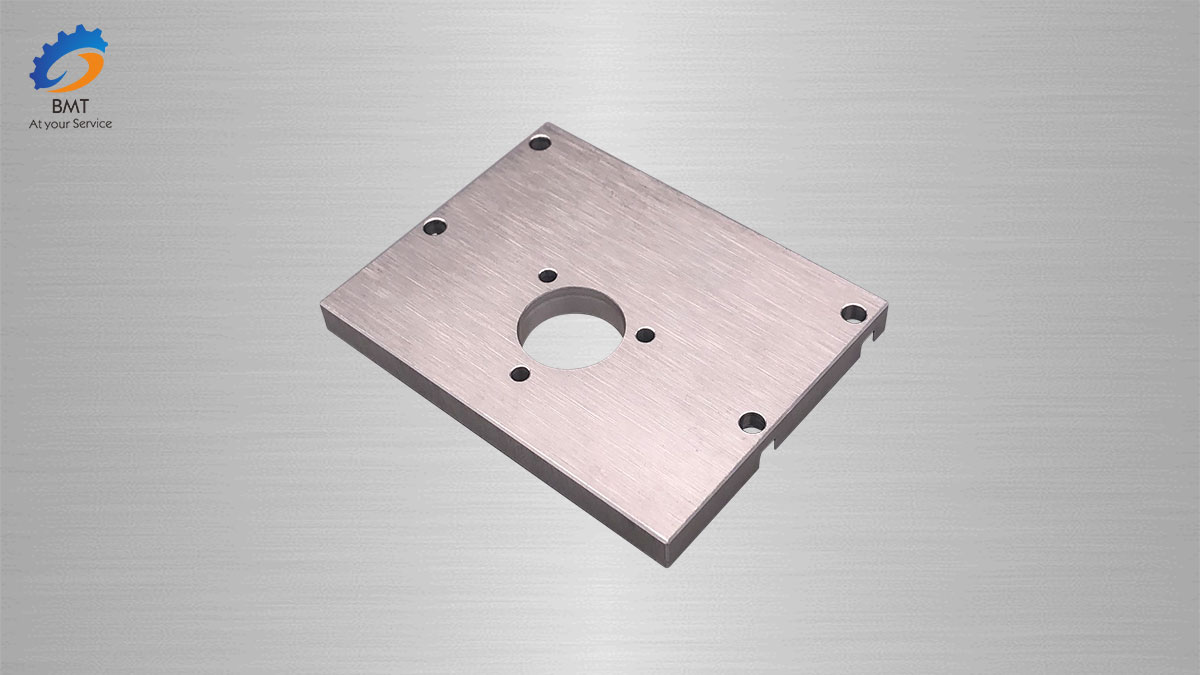

CNC Machining Processing Analysis

Txheej txheem kev soj ntsuam

Cov teeb meem kev lag luam ntawm CNC machining ntawm cov txheej txheem ua tiav muaj ntau yam kev sib tw. Cov hauv qab no sib xyaw ua ke muaj peev xwm thiab yooj yim ntawm kev ua haujlwm los muab qee cov ntsiab lus tseem ceeb uas yuav tsum tau txheeb xyuas thiab tshuaj xyuas.

Folding qhov ntev yuav tsum ua raws li cov yam ntxwv ntawm CNC machining

Hauv CNC programming, qhov loj thiab txoj hauj lwm ntawm tag nrho cov ntsiab lus, kab, thiab qhov chaw yog nyob ntawm qhov programming keeb kwm. Yog li ntawd, nws yog qhov zoo tshaj plaws los muab qhov kev sib koom ua ke ncaj qha rau ntawm qhov kos duab, lossis sim hais qhov loj me nrog tib datum.

Cov xwm txheej rau folding geometric ntsiab yuav tsum ua kom tiav thiab raug

Nyob rau hauv lub programming, tus programmer yuav tsum nkag siab tag nrho cov geometric element tsis uas yog contour ntawm ib feem thiab kev sib raug zoo ntawm geometric ntsiab. Vim hais tias tag nrho cov ntsiab lus geometric ntawm lub contour ntawm ib feem yuav tsum tau txhais thaum lub sij hawm tsis siv neeg programming, lub coordinates ntawm txhua lub node yuav tsum tau xam thaum lub sij hawm phau ntawv programming. Txawm hais tias qhov twg yog qhov tsis meej lossis tsis meej, programming tsis tuaj yeem ua. Txawm li cas los xij, vim qhov tsis txaus siab lossis tsis saib xyuas los ntawm cov neeg tsim qauv hauv cov txheej txheem tsim, feem ntau tsis tiav lossis tsis meej, xws li arc thiab kab ncaj, arc thiab arc seb lawv puas yog tangent lossis sib tshuam lossis sib cais. Yog li ntawd, thaum tshuaj xyuas thiab tshuaj xyuas cov duab kos, koj yuav tsum ceev faj thiab tiv tauj tus tsim qauv hauv lub sijhawm yog tias koj pom muaj teeb meem.

Txhim khu kev qha folding positioning datum

Nyob rau hauv CNC machining, cov txheej txheem machining feem ntau yog concentrated, thiab nws yog ib qho tseem ceeb heev kom nrhiav tau lawv nyob rau tib lub hauv paus. Yog li ntawd, nws yog ib qho tsim nyog los teeb tsa qee qhov kev pabcuam cov ntaub ntawv, lossis ntxiv qee cov txheej txheem tus thawj coj ntawm qhov khoob.

Fold uniform geometry hom lossis loj

Nws yog qhov zoo dua los txais yuav ib hom duab geometric lossis qhov loj me rau cov duab thiab cov kab noj hniav sab hauv, kom tus naj npawb ntawm cov cuab yeej hloov pauv tuaj yeem raug txo qis, thiab nws kuj tseem tuaj yeem siv cov kev tswj hwm lossis ib qho kev pabcuam tshwj xeeb kom txo qhov ntev. ntawm qhov kev pab cuam. Cov duab ntawm cov khoom yog symmetrical raws li qhov ua tau, uas yooj yim rau kev ua haujlwm nrog daim iav machining muaj nuj nqi ntawm CNC tshuab cuab yeej kom txuag tau lub sijhawm programming.