mus rau boost, ua tej yam khoom zoo nyob rau hauv txoj kab nrog kev ua lag luam thiab buyer standard xav tau. Peb lub tuam txhab muaj cov txheej txheem kev lees paub zoo heev tshwm sim los tsim rau Tus Nqi Sib Tw rau Tuam Tshoj Kev Sib Tham nrog OEM Kev Pabcuam, "Hloov rau ntau dua!" yog peb cov lus hais tias, "Lub ntiaj teb loj dua nyob ntawm peb, yog li cia peb hlub nws!" Hloov rau koj ntau dua! Koj puas yog tag nrho?

mus rau boost, ua tej yam khoom zoo nyob rau hauv txoj kab nrog kev ua lag luam thiab buyer standard xav tau. Peb lub tuam txhab muaj cov txheej txheem kev lees paub zoo heev tshwm sim los tsim rauTuam Tshoj Machining, Tig qhov chaw, Peb cov kev daws teeb meem muaj kev lees paub hauv lub tebchaws rau cov khoom tsim nyog, cov khoom zoo, tus nqi pheej yig, tau txais tos los ntawm cov tib neeg thoob plaws ntiaj teb. Peb cov khoom yuav txuas ntxiv txhim kho nyob rau hauv qhov kev txiav txim thiab tshwm sim rau kev koom tes nrog koj, Yeej yuav tsum muaj ib qho ntawm cov khoom xav paub rau koj, nco ntsoov qhia rau koj paub. Peb yuav txaus siab muab cov lus hais rau koj thaum tau txais cov ncauj lus kom ntxaws.

Koj Precision Machining Chaw Tsim Tshuaj

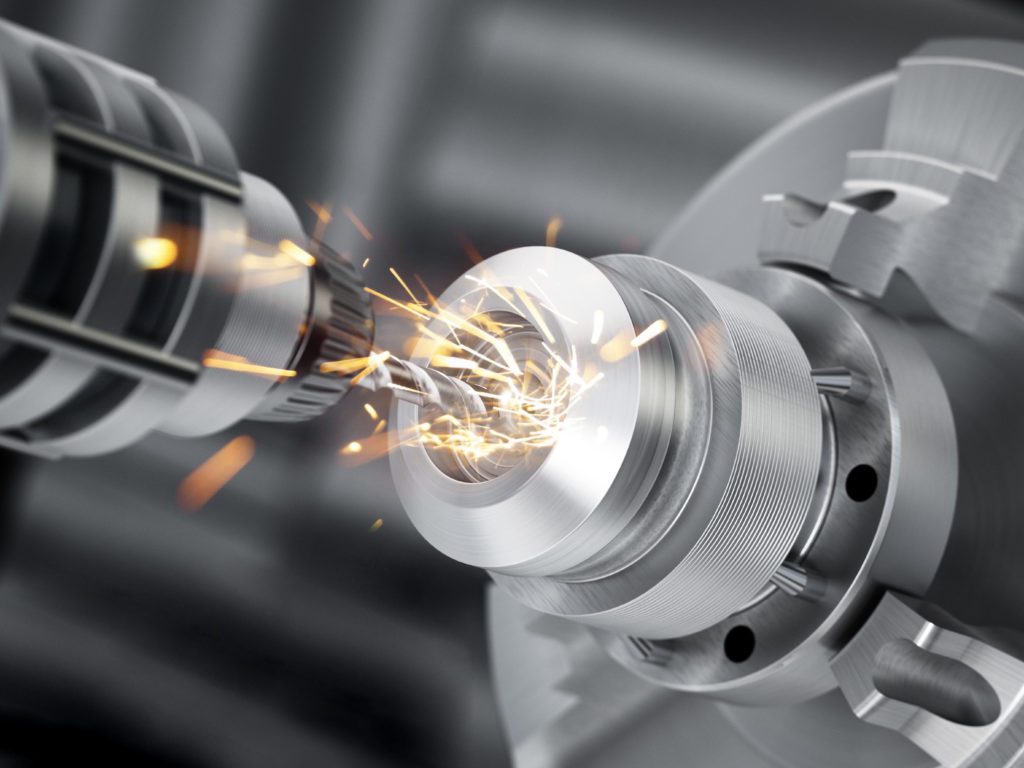

PRECISION MACHINING

Precision machining yog txheej txheem uas cov duab lossis kev ua haujlwm ntawm cov khoom hloov pauv los ntawm kev ua cov tshuab. Raws li lub xeev kub ntawm lub workpiece yuav tsum tau ua, nws muab faib ua txias ua thiab kub ua. Feem ntau, kev ua haujlwm ntawm chav tsev kub, thiab tsis ua rau cov tshuaj lom neeg lossis theem hloov ntawm cov khoom ua haujlwm, nws yog hu ua kev ua haujlwm txias. Feem ntau, kev ua haujlwm siab dua lossis qis dua qhov kub ib txwm yuav ua rau cov tshuaj lom neeg lossis theem hloov ntawm cov khoom ua haujlwm, uas yog hu ua thermal processing. Kev ua haujlwm txias tuaj yeem muab faib ua kev txiav thiab kev ua haujlwm siab raws li qhov sib txawv ntawm cov txheej txheem ua. Thermal processing feem ntau suav nrog kev kho cua sov, forging, casting thiab vuam.

Auto parts processing yog chav tsev uas tsim tag nrho cov khoom pib ua haujlwm thiab cov khoom lag luam uas ua haujlwm rau kev ua haujlwm ntawm nws pib. Raws li lub hauv paus ntawm kev lag luam tsheb, tsheb qhov chaw yog qhov tsim nyog los txhawb kev txhim kho kom ruaj khov thiab noj qab nyob zoo ntawm kev lag luam tsheb. Tshwj xeeb, tam sim no kev ywj pheej txoj kev loj hlob thiab kev tsim kho tshiab hauv kev lag luam tsheb uas tau ua kom muaj zog thiab nyob rau hauv tag nrho viav vias yuav tsum muaj qhov system muaj zog los txhawb nws. Lub tsheb ywj pheej hom thiab thev naus laus zis tshiab xav tau cov khoom thiab cov khoom siv los ua lub hauv paus, thiab kev ywj pheej tshiab ntawm cov khoom thiab cov khoom muaj lub zog tsav tsheb rau kev loj hlob ntawm kev lag luam tsheb. Lawv cuam tshuam thiab cuam tshuam nrog ib leeg. Tsis muaj lub npe ywj pheej ntawm cov tsheb ua tiav, thiab cov khoom muaj zog. R & D thiab innovation muaj peev xwm ntawm lub tuam txhab yog qhov nyuaj rau tawg, thiab tsis muaj kev txhawb nqa ntawm lub zog tivthaiv, nws yuav nyuaj rau cov lag luam ywj pheej los ua loj thiab muaj zog.

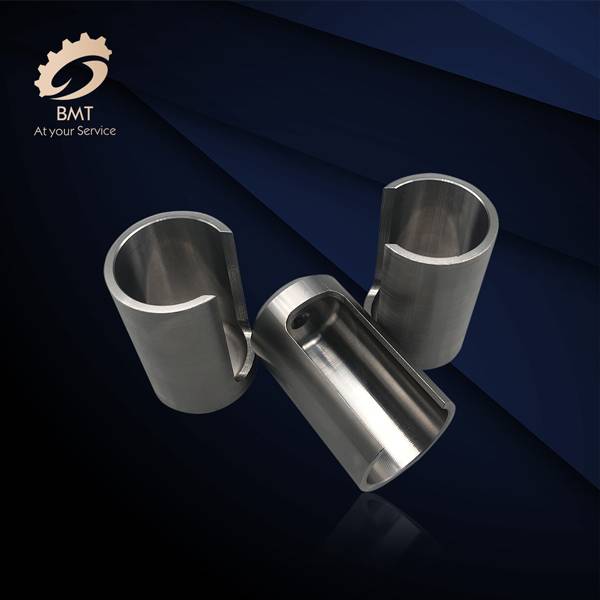

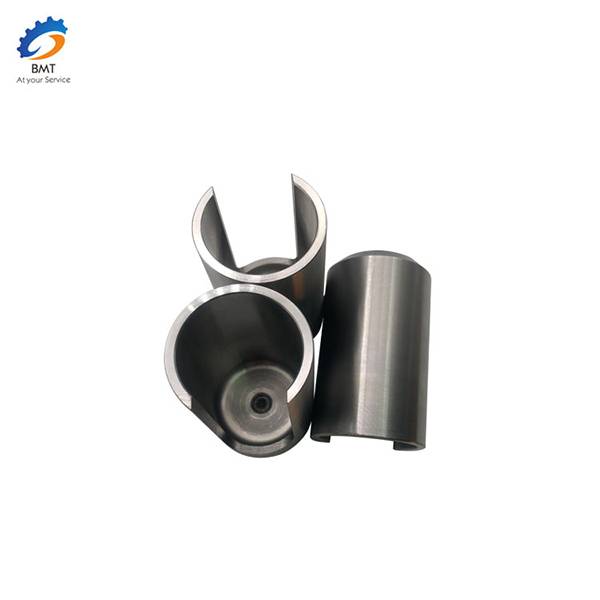

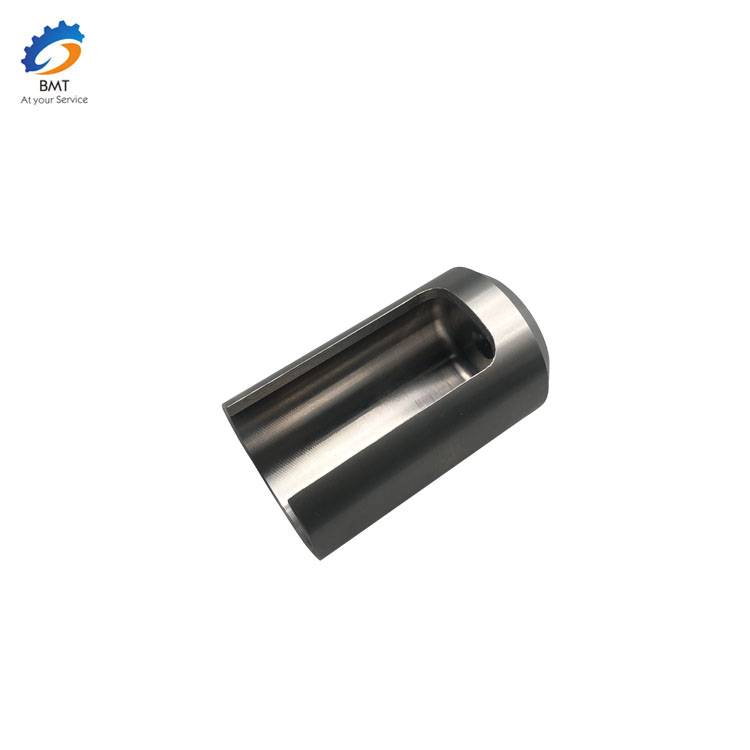

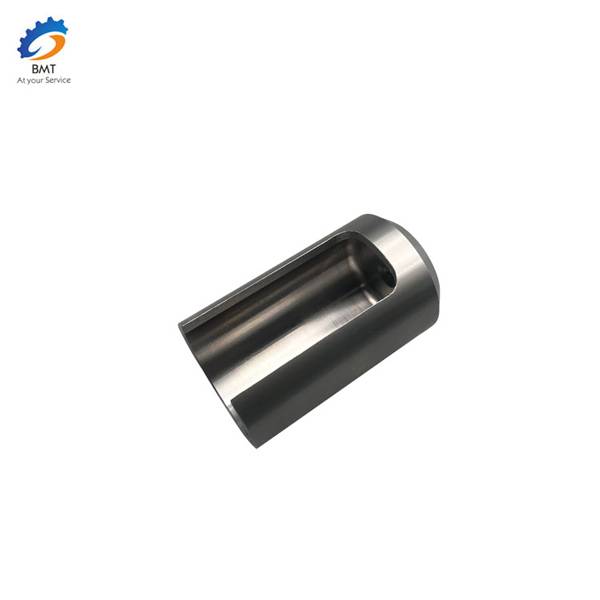

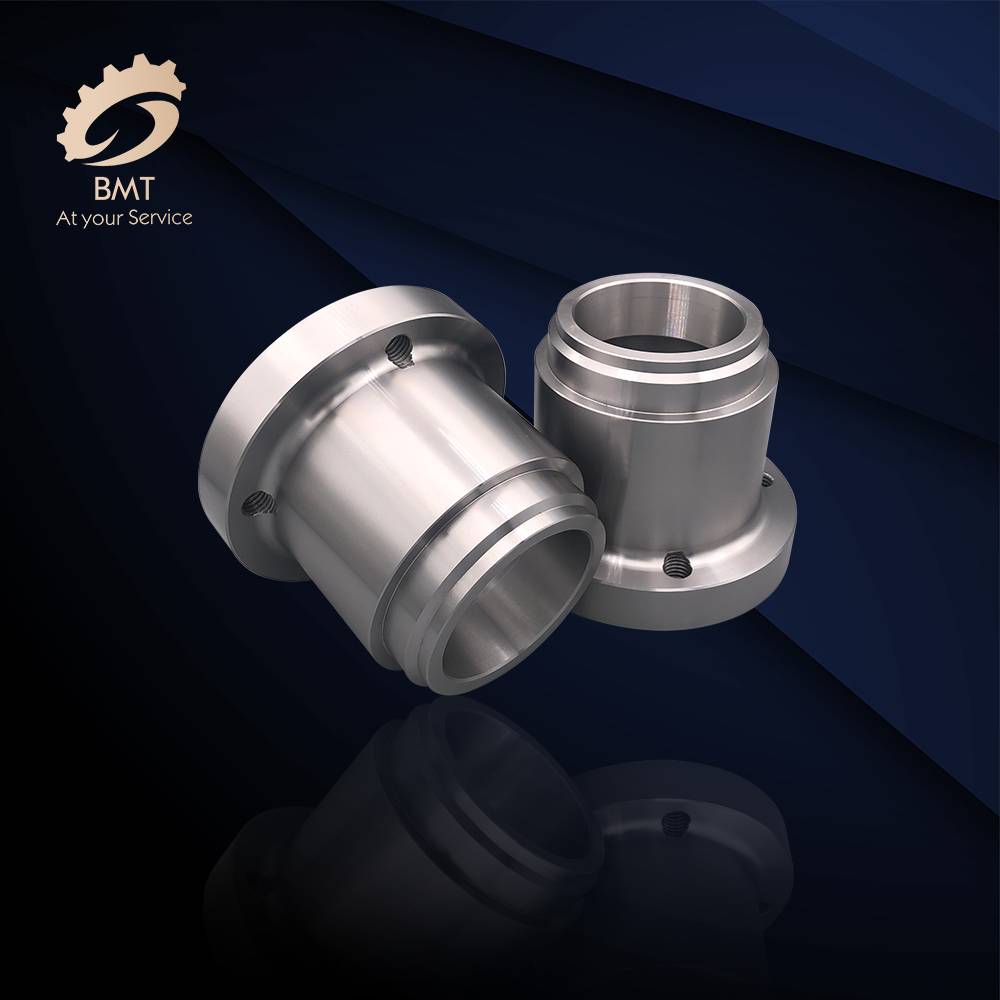

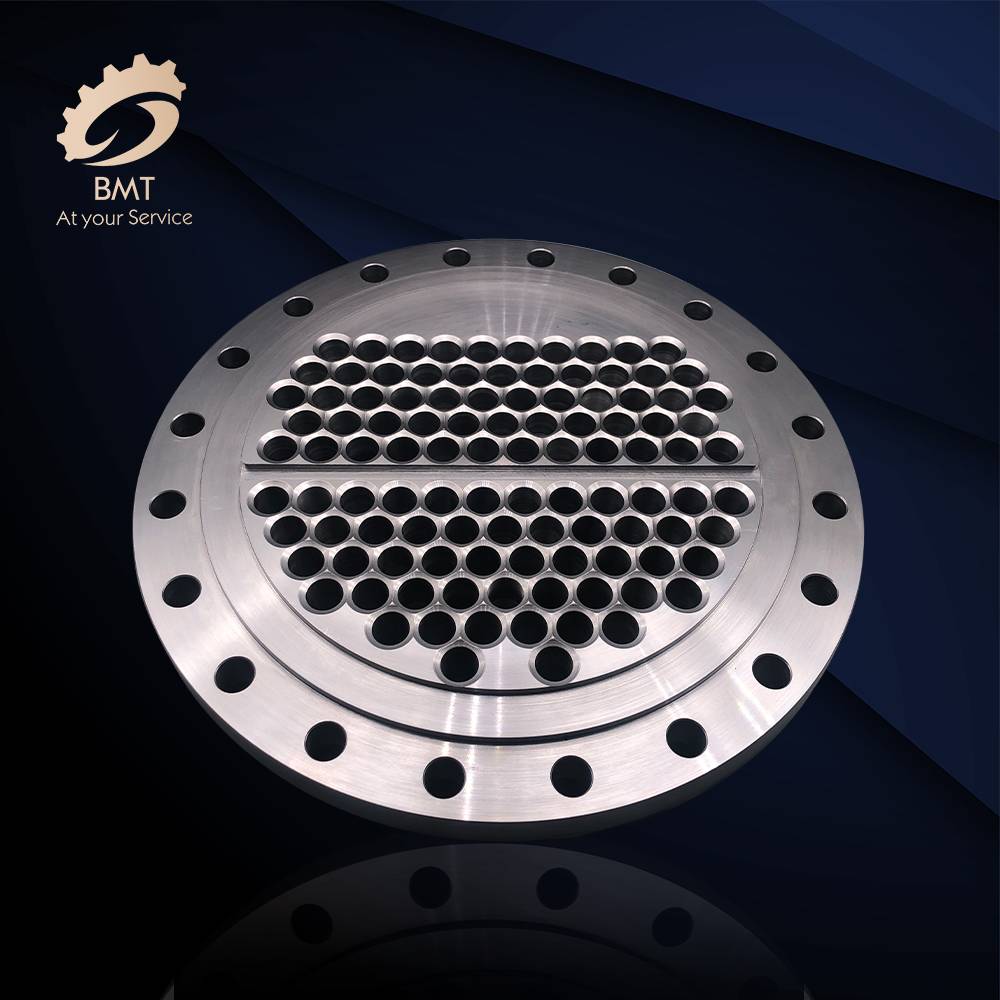

Cov khoom xa mus rau ib qho chaw uas tsis tuaj yeem sib cais hauv cov tshuab. Lawv yog cov hauv paus ntsiab lus ntawm lub tshuab thiab lub hauv paus tsev nyob rau hauv lub tshuab tsim cov txheej txheem. Cov txheej txheem tsim khoom feem ntau tsis tas yuav muaj txheej txheem sib dhos. Xws li lub tes tsho, bushes, txiv ntseej, crankshafts, hniav, iav, cams, txuas pas nrig lub cev, txuas tus pas nrig taub hau, thiab lwm yam. Rau peb precision machining, cov txheej txheem yog nruj heev, thiab cov txheej txheem muaj xws li txiav rau hauv thiab tawm. Muaj cov kev cai tshwj xeeb rau qhov loj thiab qhov tseeb, xws li 1mm ntxiv lossis rho tawm micrometers, thiab lwm yam. Yog tias qhov loj me, nws yuav raug pov tseg. Lub sijhawm no, nws yog qhov sib npaug rau kev rov ua dua tshiab, siv sijhawm ntev thiab ua haujlwm hnyav, thiab qee zaum txawm tias tag nrho cov khoom ua tiav tau muab pov tseg. Qhov no tau ua rau muaj kev nce nqi, thiab tib lub sijhawm, cov khoom siv tsis raug.

Qee cov cuab yeej siv tsis tuaj yeem ua tiav pwm ua tiav, xws li qee qhov kab noj hniav nrog R cov kaum me me; electrodes yog ua los ntawm hluav taws xob pulse. Cov no feem ntau yog ua los ntawm tooj liab lossis graphite. Txoj kev loj hlob sai ntawm pwm tsim tshuab tau dhau los ua ib feem tseem ceeb ntawm kev tsim khoom siv niaj hnub no. Niaj hnub nimno pwm tsim tshuab yog tsim nyob rau hauv cov kev taw qhia ntawm accelerating cov ntaub ntawv tsav tsheb, kev txhim kho kev lag luam yooj, agile manufacturing thiab system kev koom ua ke. Nws yog tshwj xeeb tshaj yog manifested nyob rau hauv lub CAD / CAM technology ntawm cov pwm, lub laser sai prototyping tshuab ntawm pwm, precision forming tshuab ntawm pwm, thiab lub ultra-precision ua tshuab ntawm pwm. Cov pwm tsim siv cov txheej txheem finite element thiab txoj kev ciam teb los ua cov txheej txheem khiav, txias thiab cua sov. Dynamic simulation thev naus laus zis, pwm CIMS thev naus laus zis, kev tsim cov thev naus laus zis xws li pwm DNM thev naus laus zis thiab kev tswj cov lej tau tsim.

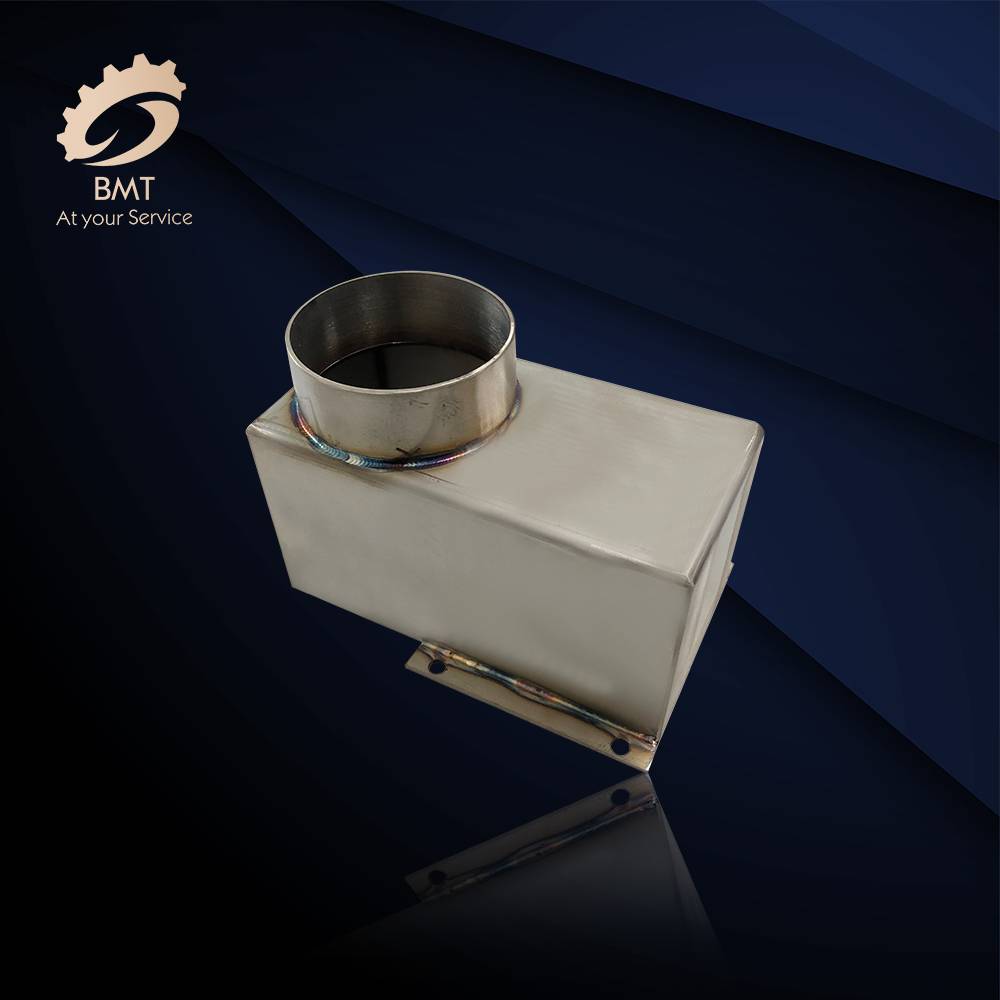

Lwm yam khoom thiab ntim piv txwv

Machining yog ib lub sij hawm tsim khoom uas suav nrog ntau yam technologies thiab cov txheej txheem. Nws tuaj yeem txhais tau hais tias yog tus txheej txheem ntawm kev tshem tawm cov khoom siv los ntawm lub tshuab ua haujlwm uas siv lub zog-tsav tshuab cov cuab yeej los tsim nws rau hauv kev npaj tsim. Feem ntau cov khoom siv hlau thiab cov khoom xav tau qee yam ntawm machining thaum lub sijhawm tsim khoom. Lwm cov ntaub ntawv, xws li yas, roj hmab, thiab cov khoom siv ntawv, kuj feem ntau yog tsim los ntawm cov txheej txheem machining.

Hom Machining cuab yeej

Muaj ntau ntau hom machining cov cuab yeej, thiab lawv yuav siv tau ib leeg los yog ua ke nrog lwm cov cuab yeej ntawm ntau cov kauj ruam ntawm kev tsim cov txheej txheem kom ua tiav cov phiaj xwm geometry. Cov pawg loj ntawm cov cuab yeej machining yog:

Cov cuab yeej tho txawv: Cov no feem ntau yog siv los ua cov cuab yeej ua tiav kom loj qhov uas tau txiav rau hauv cov khoom.

Cov cuab yeej txiav: Cov cuab yeej xws li saws thiab txiab yog cov piv txwv ntawm cov khoom siv txiav. Lawv feem ntau siv los txiav cov khoom nrog qhov ntev, xws li cov ntawv hlau, rau hauv cov duab uas xav tau.

Drilling cov cuab yeej: Cov pawg no muaj ob-edged rotating cov cuab yeej uas tsim cov qhov sib npaug sib npaug mus rau qhov axis ntawm kev sib hloov.

Cov cuab yeej sib tsoo: Cov cuab yeej no siv lub log tig kom ua tiav qhov zoo los yog ua kom pom kev txiav ntawm lub workpiece.

Xa koj cov lus rau peb:

-

2019 Tseeb Tsim Tuam Tshoj Rapid Prototype 6061 7 ...

-

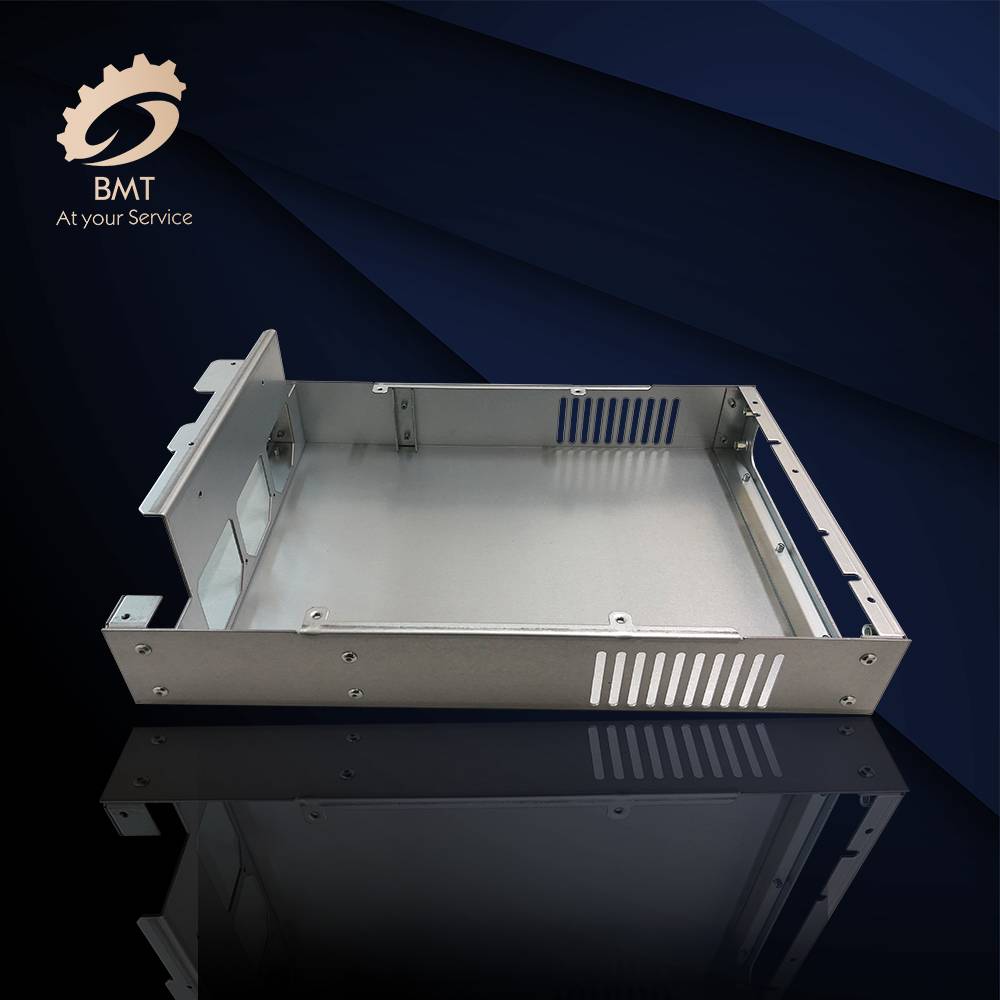

Tuam Tshoj lag luam wholesale Tuam Tshoj Tsim Sheet Hlau C ...

-

Pheej yig Hoobkas Tuam Tshoj Custom Precision CNC Mac ...

-

15 Xyoo Exporter Tuam Tshoj OEM Customized Tshuab ...

-

Tus nqi sib tw rau Tuam Tshoj Custom OEM High Pre ...

-

Chaw tsim tshuaj paus rau Tuam Tshoj CNC Machining Customized ...