Mechanical Machining Hom

Main Classification

Muaj ob lub ntsiab ntawm machining: phau ntawv machining thiab CNC machining.Manual processing yog hais txog cov txheej txheem ntawm kev ua ntau yam ntaub ntawv los ntawm kev tuav haujlwm ntawm cov cuab yeej siv tshuab xws li tshuab milling, lathes, drilling tshuab thiab sawing tshuab los ntawm cov neeg ua haujlwm tshuab.Manual machining yog tsim rau cov ntim qis, yooj yim ib feem ntau lawm.CNC machining (CNC) yog hais txog kev siv cov khoom siv CNC los ntawm cov neeg ua haujlwm kho tshuab rau kev ua haujlwm.Cov khoom siv CNC no suav nrog cov chaw machining, tig thiab milling chaw, xaim EDM cov cuab yeej, xov txiav tshuab, thiab lwm yam. Feem ntau ntawm cov khw muag khoom siv CNC machining tshuab.Los ntawm kev ua haujlwm, txoj haujlwm ua haujlwm (X, Y, Z) ntawm qhov chaw ua haujlwm hauv Cartesian kev tswj hwm qhov system raug hloov mus rau hauv cov lus programming.

CNC maub los ntawm CNC tshuab cuab yeej tswj lub axis ntawm CNC tshuab cuab yeej los ntawm kev txheeb xyuas thiab txhais cov lus programming, thiab txiav tawm cov ntaub ntawv raws li xav tau., thiaj li yuav tau txais lub workpiece tiav.CNC machining txheej txheem workpieces nyob rau hauv ib tug tas mus li yam thiab yog haum rau loj qhov ntau ntawm qhov chaw nrog complex duab.

Kev Siv Tshuab

Lub rooj cob qhia machining tuaj yeem siv CAD / CAM (Computer Aided Design Computer Aided Manufacturing) system kom tau txais kev pabcuam CNC tshuab cuab yeej.Lub geometry ntawm ib feem yog cia li pauv los ntawm CAD system mus rau CAM system, thiab tus kws kho tshuab xaiv ntau txoj kev machining ntawm lub tshuab virtual.Thaum tus machinist xaiv ib txoj kev machining, CAD/CAM system tuaj yeem tso tawm CNC code, feem ntau hu ua G code, thiab nkag mus rau tus lej ntawm CNC tshuab cuab yeej rau kev ua haujlwm tiag tiag.

Lwm yam khoom siv

Cov khoom siv tom qab lub Hoobkas, xws li hlau txiav tshuab cuab yeej (xws li tig, milling, planing, inserting thiab lwm yam khoom), yog hais tias qhov chaw ntawm cov cuab yeej xav tau rau kev tsim khoom yog tawg thiab yuav tsum tau kho, lawv yuav tsum tau xa mus rau lub machining. rhiav kev kho lossis kev ua haujlwm.Txhawm rau kom ntseeg tau tias kev ua tiav ntawm kev tsim khoom, cov tuam txhab dav dav muaj kev cob qhia machining, uas yog lub luag haujlwm tseem ceeb rau kev saib xyuas cov khoom siv ntau lawm.

Cov txheej txheem ua haujlwm

I. Txheej txheem cej luam

Cov txheej txheem kev khiav hauj lwm no ua rau cov lus qhia tshwj xeeb thiab cov ncauj lus kom ntxaws rau txhua tus neeg ua haujlwm ua haujlwm hauv machining kom paub meej qhov zoo ntawm txhua qhov machined.

2. Scope ntawm daim ntawv thov

Txoj cai no qhia txog cov haujlwm tshwj xeeb ntawm cov neeg ua haujlwm machining (xws li tig, milling, drilling, planing, sib tsoo, shearing, thiab lwm yam) thaum ua haujlwm.

3. Kev cai dav dav

Mechanical processing yuav tsum tau ua raws li cov kev cai no thaum lub sij hawm ua ntau yam tshuab.

Xa koj cov lus rau peb:

-

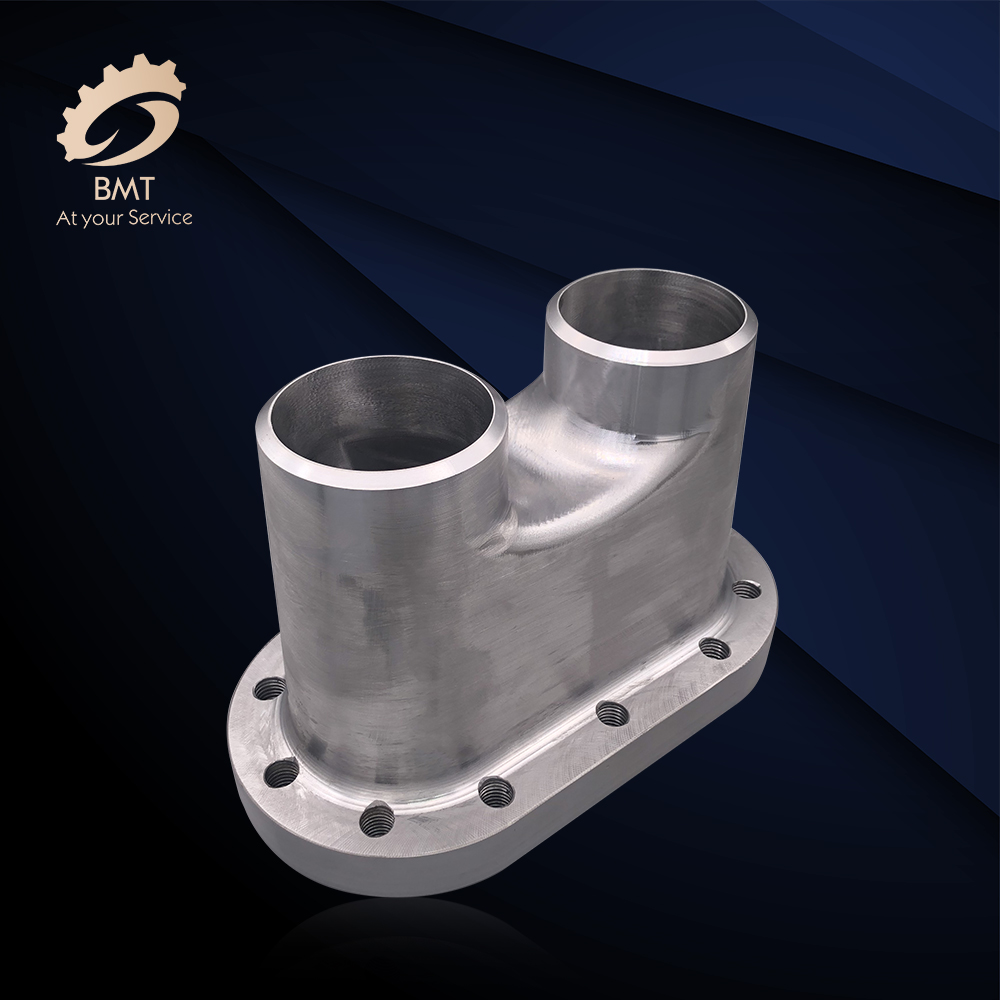

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining qhov chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Pipes / Tubes