Precision Machining Parts thiab Sheet Hlau Parts

Qhia peb Precision Machining Parts thiab Sheet Hlau Khoom, tsim kom tau raws li cov qauv zoo tshaj plaws thiab kev ua haujlwm zoo. Peb cov khoom tau ua tib zoo tsim los ntawm kev siv cov txheej txheem kev tsim khoom siab heev thiab cov cuab yeej siv thev naus laus zis los xyuas kom meej meej, ua haujlwm ntev, thiab kev ntseeg tau.

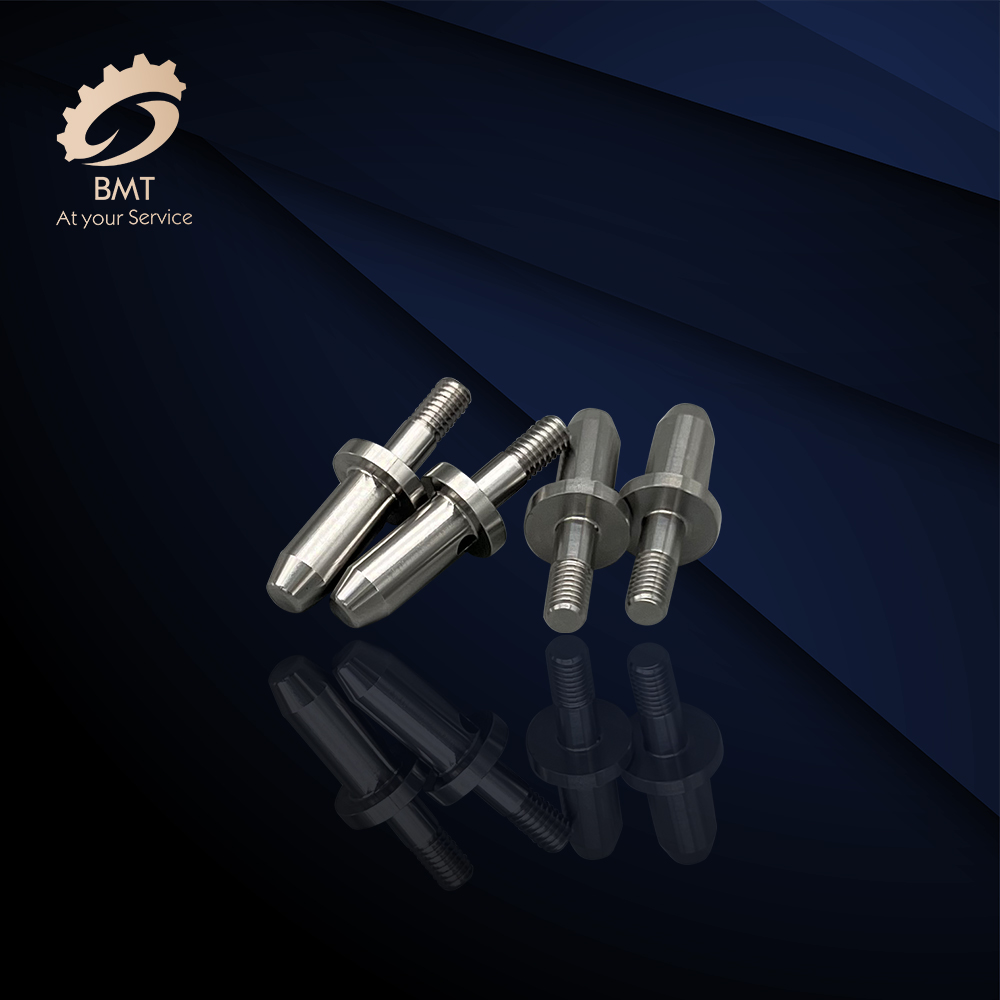

Machining qhov chaw:Pebmachining qhov chawyog engineered kom xa exceptional raug thiab sib xws, ua rau lawv zoo tagnrho rau ntau yam kev lag luam daim ntaub ntawv. Txawm hais tias koj xav tau cov khoom siv dav dav rau aerospace, tsheb, khoom siv kho mob, lossis lwm yam kev lag luam, peb cov khoom siv tshuab yog tsim los ua kom tau raws li koj cov kev xav tau tshwj xeeb. Peb siv cov cuab yeej CNC machining lub xeev thiab ntiav cov kws tshaj lij los tsim cov khoom nrog nruj tolerances thiab intricate geometries. Los ntawm prototypes mus rau high-volume ntau lawm khiav, peb muaj peev xwm xa precision machining qhov chaw uas tshaj qhov koj xav tau.

Sheet Hlau:

Pebcov khoom siv hlauyog crafted nrog precision thiab saib xyuas kom meej, muab ntau yam kev daws teeb meem rau ntau yam fabrication xav tau. Txawm hais tias koj xav tau kev cai enclosures, brackets, panels, los yog lwm yam ntaub ntawv hlau Cheebtsam, peb muaj kev txawj ntse los xa cov khoom zoo uas ua tau raws li koj cov specifications. Peb ua hauj lwm nrog ntau yam ntaub ntawv, xws li stainless hlau, txhuas, thiab carbon hlau, thiab tuaj yeem ua kom haum rau ntau yam thicknesses thiab ntau thiab tsawg. Peb cov txheej txheem kev tsim cov ntawv hlau suav nrog kev txiav, khoov, vuam, thiab ua tiav, kom ntseeg tau tias cov khoom kawg ua tau raws li cov qauv zoo tshaj plaws thiab kev ua haujlwm zoo.

Quality Assurance:

Ntawm peb lub chaw, qhov zoo yog nyob rau hauv pem hauv ntej ntawm txhua yam peb ua. Peb tau siv cov kev tswj xyuas nruj nruj thoob plaws hauv cov txheej txheem tsim khoom kom ntseeg tau tias txhua yam khoom ua tau raws li cov qauv kev ua tau zoo tshaj plaws. Los ntawm kev tshuaj xyuas cov khoom siv raw mus rau qhov kawg ntawm cov khoom kuaj, peb ua raws li cov lus qhia nruj kom lav qhov kev ntseeg tau thiab kev ua tau zoo ntawm peb cov khoom siv thiab cov khoom siv hlau. Peb qhov kev cog lus rau kev ua tau zoo yog cuam tshuam los ntawm kev txaus siab ntawm peb cov neeg siv khoom thiab kev sib koom ua tiav ntawm peb cov khoom rau hauv ntau yam kev lag luam.

Customization:

Peb nkag siab tias txhua qhov project muaj cov kev cai tshwj xeeb, uas yog vim li cas peb muab cov kev xaiv kho kom haum rau peb cov khoom raws li koj cov kev xav tau tshwj xeeb. Txawm hais tias koj xav tau kev cai machining qhov chaw nrog cov geometry nyuaj lossis cov khoom siv hlau uas muaj qhov ntev thiab ua tiav, peb pab neeg tau mob siab rau ua haujlwm ze nrog koj kom coj koj lub zeem muag mus rau lub neej. Peb muaj kev txawj ntse thiab hloov tau raws li cov kev cai thov thiab xa cov khoom uas ua raws li koj cov specifications.

Xaus:

Nrog pebprecision machining qhov chawthiab cov khoom siv hlau, koj tuaj yeem ntseeg tau tias koj tau txais cov khoom zoo tshaj plaws uas tau tsim los rau kev ua haujlwm thiab kev ua haujlwm ntev. Txawm hais tias koj xav tau precision machining qhov chaw rau cov ntawv thov tseem ceeb lossis cov khoom siv hlau nplaum rau koj cov kev xav tau fabrication, peb muaj peev xwm thiab kev txawj ntse kom xa cov txiaj ntsig tshwj xeeb. Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov khoom thiab peb tuaj yeem pab txhawb koj li kev tsim khoom.

Xa koj cov lus rau peb:

-

Axis High Precision CNC Machining Qhov Chaw

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes

-

Aluminium CNC Machining qhov chaw

-

Auto Parts Machining

-

CNC Auto Parts Machined Parts

-

CNC Machined Cheebtsam

-

Aluminium Sheet Hlau Fabrication

-

Automotive Kev Lag Luam

-

Centerless sib tsoo

-

CNC Machining Advantages

-

CNC Machining Aluminium Qhov Chaw