Cov Thin-walled Parts no ua li cas?

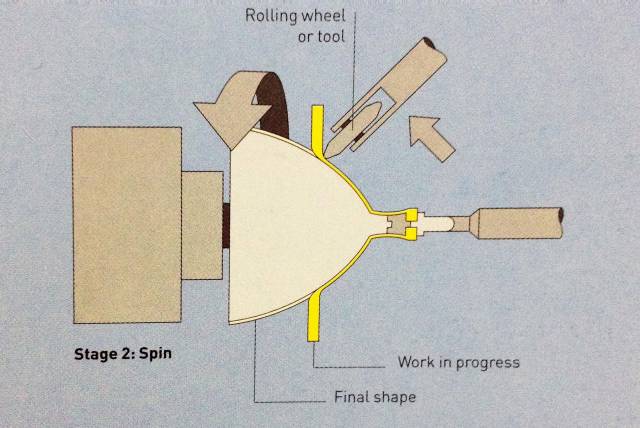

Hlau spinning yog symmetrical rotational txheej txheem rau cov ntawv hlau. Lub spindle tsav qhov khoob thiab cov pwm core tig, thiab tom qab ntawd lub rotary log siv lub siab rau lub rotating dawb paug. Vim lub zog teb ntawm lub ntsiab ncej ntawm lub tshuab spinning thiab longitudinal thiab transverse feed motion ntawm lub cuab tam, lub zos yas deformation maj mam nthuav mus rau tag nrho cov dawb paug, yog li tau txais ntau yam duab ntawm hollow rotating lub cev qhov chaw.

Tus nqi txheej txheem: pwm tus nqi (qis), ib daim nqi (nruab nrab)

Yam khoom: rooj tog, teeb, aerospace, tsheb thauj mus los, tableware, hniav nyiaj hniav kub, thiab lwm yam.

Yield haum: me me thiab nruab nrab batch ntau lawm

Nto Zoo:

Qhov zoo tshaj plaws yog nyob ntawm tus neeg teb xov tooj kev txawj thiab ntau lawm ceev

Machining ceev: Nruab nrab mus rau siab ntau lawm ceev, nyob ntawm qhov loj me, complexity thiab daim ntawv hlau thickness

Cov ntaub ntawv siv tau:

Haum rau cov ntawv sov sov xws li stainless hlau, tooj dag, tooj liab, txhuas, titanium, thiab lwm yam.

Kev txiav txim siab tsim:

1. Hlau spinning tsuas yog tsim nyog rau kev tsim cov rotationally symmetrical qhov chaw, thiab qhov zoo tshaj plaws cov duab yog hemispherical nyias-plhaub hlau qhov chaw;

2. Rau qhov chaw tsim los ntawm cov hlau spinning, lub taub sab hauv yuav tsum tswj tsis pub dhau 2.5m.

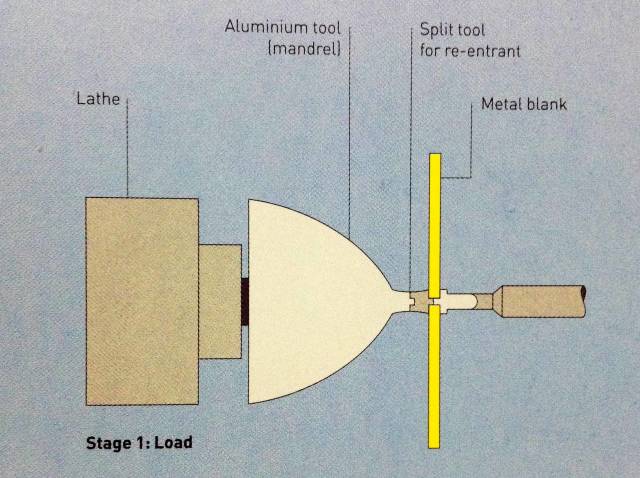

Kauj Ruam 1: Txhim kho cov ntawv txiav puag ncig ntawm lub tshuab mandrel.

Kauj Ruam 2: Lub mandrel tsav lub voj voog hlau phaj kom tig ntawm qhov kev kub ceev, thiab lub cuab yeej nrog tus khiav pib nias cov hlau nto kom txog thaum lub phaj hlau ua tiav rau lub puab phab ntsa ntawm cov pwm.

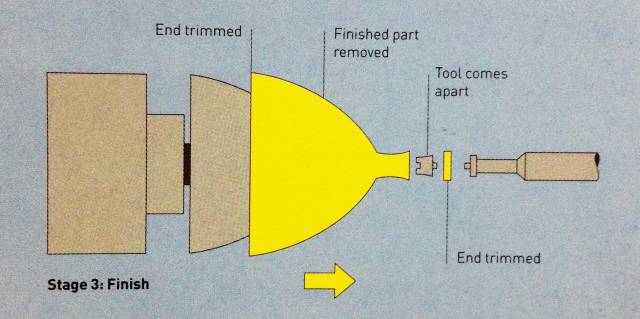

Kauj Ruam 3: Tom qab molding tiav, lub mandrel raug tshem tawm thiab sab saum toj thiab hauv qab ntawm ib feem raug txiav tawm rau demolding.

Xa koj cov lus rau peb:

-

Aluminium CNC Machining qhov chaw

-

Aluminium Sheet Hlau Fabrication

-

Axis High Precision CNC Machining Qhov Chaw

-

CNC Machined Parts rau Ltalis

-

CNC Machining Aluminium Qhov Chaw

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Yeeb Nkab / Tubes