CNC High Precision Machining Qhov Chaw

Nyob rau hauv niaj hnub kev lag luam kev lag luam ceev ceev, precision thiab efficiency yog qhov tseem ceeb rau cov lag luam kom nyob twj ywm kev sib tw.Qhov kev xav tau ntawm cov khoom siv zoo, tsis tu ncua, thiab ua tau sai sai tau ua rau kev txhim kho ntawm cov tshuab machining siab heev.Ntawm lawv,CNC Machiningstands raws li ib tug kev ua si-hloov pauv uas revolutionizes txoj kev peb mus rau precision manufacturing.CNC (Computer Numerical Control) Machining yog cov cuab yeej siv thev naus laus zis uas siv lub khoos phis tawj software los tswj cov tshuab, kom ntseeg tau meej thiab rov ua tau.Tsis zoo li cov txheej txheem machining ib txwm muaj, uas muaj kev vam khom rau kev siv zog thiab kev cuam tshuam rau tib neeg, CNC Machining streamlines cov txheej txheem tsim khoom, muab kev txhim kho qhov tseeb, txo tib neeg kev ua yuam kev, thiab nce kev tsim khoom.

Lub plawv ntawm CNC Machining nyob rau hauv nws lub peev xwm los hloov cov qauv tsim, tsim siv software tshwj xeeb, rau hauv lub cev muaj tiag.Cov qauv tsim sib txawv, cov duab nyuaj, thiab qhov loj me uas ib zaug nyuaj kom ua tiav nrog cov txheej txheem ib txwm muaj tam sim no yooj yim ua tiav nrog CNC Machining.Los ntawm precisely tswj lub zog ntawmcov cuab yeej txiav, CNC tshuab tuaj yeem tsim cov khoom nrog qhov tsis sib xws, kev ua siab ntev, thiab lub sijhawm hloov pauv nrawm.Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm CNC Machining yog nws cov khoom siv ntau yam thoob plaws ntau yam khoom.Txawm hais tias nws cov hlau, yas, ntoo, lossis cov khoom sib xyaw, CNC Machining tuaj yeem txiav, zeb, laum, thiab ua ntau yam ntaub ntawv.Qhov kev ua tau zoo no ua rau nws muaj kev xaiv mus rau kev lag luam xws li aerospace, tsheb, kev kho mob, hluav taws xob, thiab ntau lwm yam, qhov tseeb specifications thiab high-quality finishes yog qhov tseem ceeb.

Ntxiv mus, CNC Machining boasts exceptional efficiency, tso cai rau manufacturers kom optimize lawv cov txheej txheem ntau lawm thiab txo nqi.Lub automation qhia los ntawm CNC Machining tshem tawm qhov xav tau ntawm kev teeb tsa thiab kev saib xyuas tas li, tso cai rau cov neeg ua haujlwm tsom mus rau lwm yam dej num thaum lub tshuab ua haujlwm autonomously.Qhov kev ua tau zoo no ua rau kom ntau lawm, ua rau lub sijhawm luv luv thiab ua kom cov neeg siv khoom txaus siab tag nrho.Tshaj liprecision qhov ntau lawm, CNC Machining muaj ntau yam ntawm lwm cov txiaj ntsig.Nws tso cai rau cov tuam txhab tsim qauv los ua qauv sai sai, iterate cov qauv siv zog, thiab hloov mus rau kev hloov pauv kev lag luam xav tau yooj yim.Los ntawm kev siv cov khoos phis tawj siab tshaj plaws, CNC tshuab tuaj yeem simulate cov txheej txheem tsim khoom, tshawb xyuas qhov yuam kev, thiab txhim kho cov cuab yeej txoj hauv kev, ua rau muaj txiaj ntsig zoo dua thiab txuag cov khoom siv.

Tsis tas li ntawd, CNC Machining txhawb nqa kev ruaj ntseg los ntawm kev txo cov khoom pov tseg thiab ua kom muaj kev siv ntau tshaj plaws.Los ntawm kev txiav txim siab txiav qhov tob thiab cov cuab yeej txav,CNC tshuabtxo cov khoom pov tseg piv rau cov txheej txheem ib txwm muaj.Tsis tas li ntawd, lub peev xwm los siv cov khoom seem thiab cov khoom seem rau lwm qhov txuas ntxiv ua rau muaj kev tsim khoom ruaj khov dua.Thaum nws los txog rau CNC Machining, precision, efficiency, versatility, thiab sustainability yog tus tsav tsheb tom qab nws muaj koob meej nyob rau hauv kev lag luam tsim.Los ntawm kev sib koom ua ke thev naus laus zis thev naus laus zis nrog kev txawj ntse ntawm cov neeg ua haujlwm txawj, CNC Machining tau hloov pauv txoj hauv kev uas peb mus txog qhov nyuaj ntau lawm, kev tsim qauv, thiab dhau mus.

Hauv consuav nrog, CNC Machining tau tshwm sim raws li kev ua si-hloov tshuab, hloov kho covkev tsim khoomtoj roob hauv pes.Nws cov precision tsis sib xws, ntau yam khoom muaj peev xwm, thiab cov txheej txheem tsim khoom raug nqi ua rau nws yog ib qho cuab yeej tseem ceeb rau kev lag luam thoob ntiaj teb.Los ntawm embracing CNC Machining, cov lag luam tuaj yeem ua tau raws li qhov xav tau ntau ntxiv ntawm qhov zoo, ceev, thiab raug, ua kom lawv txoj kev vam meej hauv kev lag luam niaj hnub no.

Xa koj cov lus rau peb:

-

Axis High Precision CNC Machining qhov chaw

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Pipes / Tubes

-

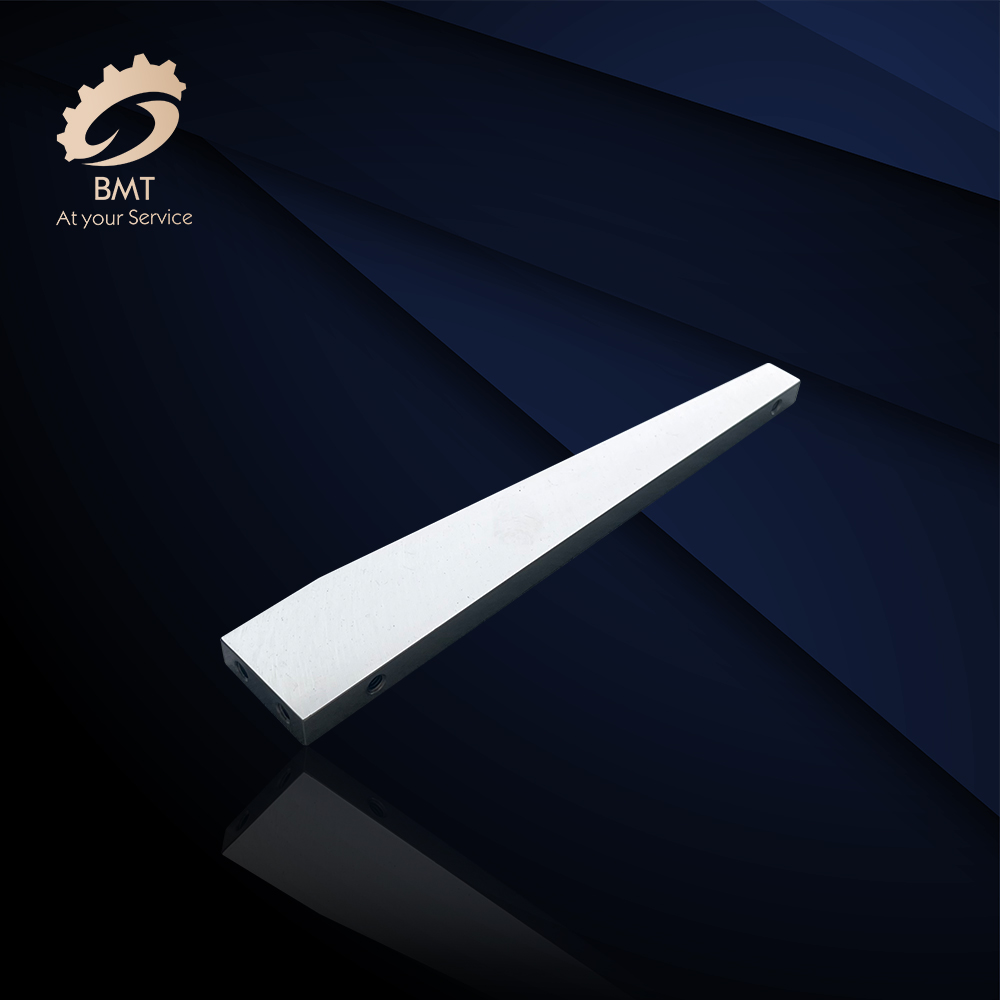

Aluminium CNC Machining qhov chaw

-

Auto Parts Machining

-

CNC Auto Parts Machined Parts

-

CNC Machined Cheebtsam

-

Aluminium Sheet Hlau Fabrication

-

Automotive Kev Lag Luam

-

Centerless sib tsoo

-

CNC Machining Advantages

-

CNC Machining Aluminium Qhov Chaw