Koj Ib-Stop Solution rau Precision Engineering Xav Tau

Ntawm BMT, peb txaus siab los ua tus thawj coj ntawm kev ua haujlwm zooCNC precisionkev daws teeb meem.Nrog rau peb lub xeev-of-the-art chaw thiab ib pab neeg ntawm cov kws tshaj lij, peb muaj ntau yam precision engineering kev pab cuam los pab rau ntau yam kev xav tau ntawm peb cov neeg siv khoom.Peb lub tuam txhab tshwj xeeb hauv CNC precision machining, cov txheej txheem kev tsim khoom lag luam uas siv lub tshuab computer suav nrog (CNC) thev naus laus zis los tsim qhov nyuaj thiab sib txawv nrog qhov tseeb tshwj xeeb.Txawm hais tias koj xav tau cov khoom tsim tshwj xeeb rau kev lag luam tsheb, cov cuab yeej siv kho mob, kev siv dav hlau, lossis lwm yam haujlwm, peb cov kev pabcuam machining precision xyuas kom meej tias koj cov kev xav tau ua tau raws li qhov tseeb thiab zoo tshaj plaws.

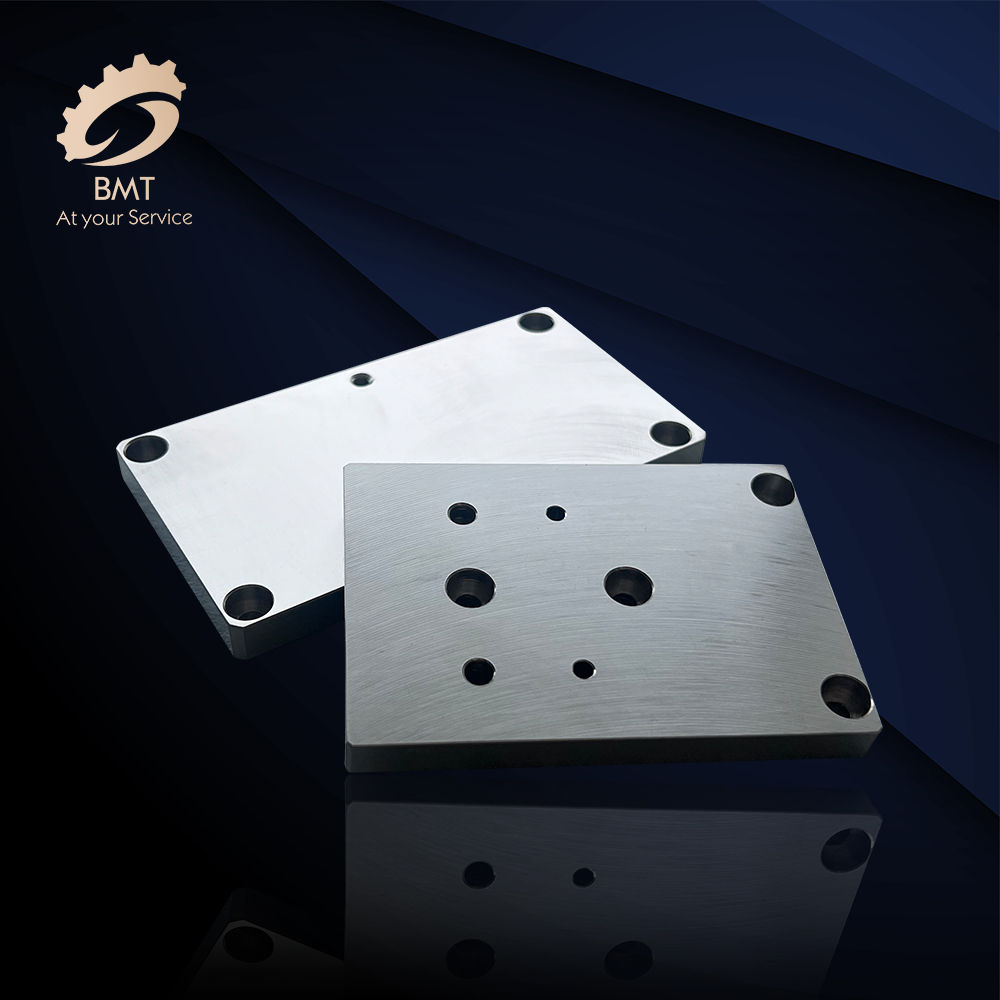

Ib qho ntawm peb lub zog tseem ceeb nyob hauv peb lub peev xwm ua haujlwm nrog ntau yam khoom siv.Los ntawm cov hlau xws li txhuas, stainless hlau, titanium, thiab tooj dag, mus rau cov khoom yas thiab cov khoom sib xyaw, peb muaj cov kws tshaj lij thiab cov cuab yeej siv los daws cov haujlwm nyuaj tshaj plaws.PebCNC precision machining peev xwmtso cai rau peb los tsim cov khoom nrog nruj tolerances, intricate designs, thiab superior nto finishes, kom ntseeg tau cov zoo tshaj plaws qauv.Ntawm BMT, peb nkag siab qhov tseem ceeb ntawm kev ua tau zoo ntawm tus nqi thiab lub sijhawm hloov pauv sai.Peb cov tshuab ua haujlwm siab heev thiab cov txheej txheem ntau lawm ua rau peb ua kom zoo tshaj qhov nrawm yam tsis muaj kev cuam tshuam rau qhov zoo.

Txawm hais tias koj xav tau ib pawg me me lossis cov khoom ntim siab, peb qhov yooj yim tso cai rau peb ua tau raws li koj qhov yuav tsum tau ua thaum ua raws li cov sijhawm kawg.Ntxiv nrog rau peb cov peev txheej precision machining, peb kuj muaj ntau yam kev pabcuam ntxiv los muab kev daws teeb meem rau peb cov neeg siv khoom.Cov kev pabcuam no suav nrog kev tsim thiab kev txhawb nqa engineering, kev tsim qauv, kev sib dhos, thiab kev tswj kom zoo.Los ntawm kev muab cov kev daws teeb meem kawg-rau-kawg, peb xyuas kom meej tias peb cov neeg tau txais kev pom zoo los ntawm lub tswv yim mus rau ntau lawm.

Peb qhov kev cog lus rau cov neeg siv khoom txaus siab yog unwavering.Peb koom tes nrog peb cov neeg siv khoom, kom ntseeg tau tias peb nkag siab tag nrho lawv cov kev xav tau thiab muab cov kev daws teeb meem rau tus kheej raws li lawv cov kev xav tau tshwj xeeb.Peb pab neeg ntawm cov kws paub txog engineers thiab cov kws tshaj lij ua haujlwm rau siab ua kom muaj kev sib txuas lus qhib, muab cov kev hloov tshiab tsis tu ncua thoob plaws hauv cov txheej txheem machining.Xaiv peb txhais tau tias koom tes nrog ib lub tuam txhab uas ua ntej qhov zoo, precision, thiab efficiency.Peb siv zog ua kom dhau qhov kev cia siab, xa cov khoom uas ua tau raws li qhov xav tau tshaj plaws.

Nrog rau peb txoj kev mob siab rau kev txhim kho tas mus li thiab kev nqis peev hauv cov thev naus laus zis tshiab, peb nyob rau hauv lub forefront ntawm precision machining kev lag luam, xyuas kom meej tias peb cov neeg tau txais cov khoom zoo tshaj plaws thiab kev pabcuam.Tiv tauj peb hnub no los tham txog kojprecision engineeringxav tau.Txawm hais tias koj xav tau tus qauv lossis kev ua haujlwm loj, peb pab pawg tau npaj los muab koj nrog CNC precision machining kev daws teeb meem.Cia siab rau BMT kom xa qhov tseeb, ua tiav, thiab ua tau zoo, txhua lub sijhawm.

Xa koj cov lus rau peb:

-

Axis High Precision CNC Machining qhov chaw

-

Titanium thiab Titanium Alloy Fittings

-

Titanium thiab Titanium Alloy Forgings

-

Titanium thiab titanium alloy hlau

-

Titanium Bars

-

Titanium Seamless Yeeb Nkab / Tubes

-

Titanium Welded Pipes / Tubes

-

Aluminium CNC Machining qhov chaw

-

Auto Parts Machining

-

CNC Auto Parts Machined Parts

-

CNC Machined Cheebtsam

-

Aluminium Sheet Hlau Fabrication

-

Automotive Kev Lag Luam

-

Centerless sib tsoo

-

CNC Machining Advantages

-

CNC Machining Aluminium Qhov Chaw